In recent years, the demand for precision and efficiency in manufacturing has led to the rapid evolution of various tools and technologies. One such advancement is the wire cutting machine, a device that has become essential in sectors such as aerospace, automotive, electronics, and metal fabrication. This article explores the functioning, types, applications, and future trends of wire cutting machines.

Understanding Wire Cutting Machines

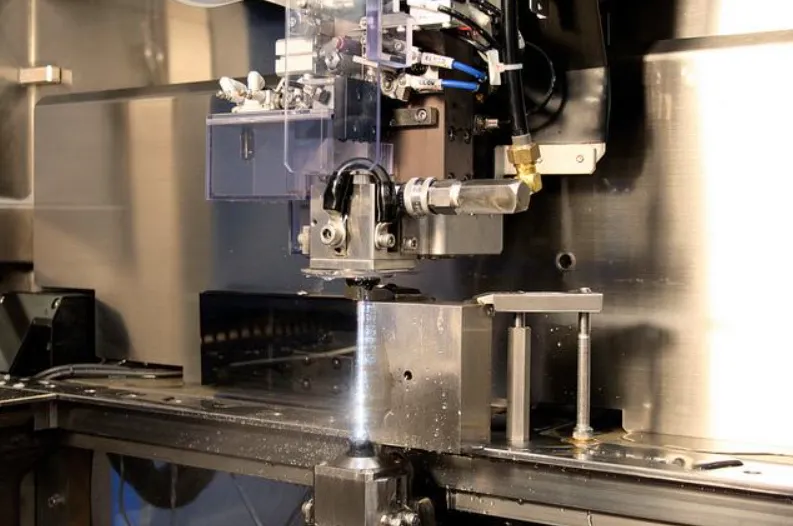

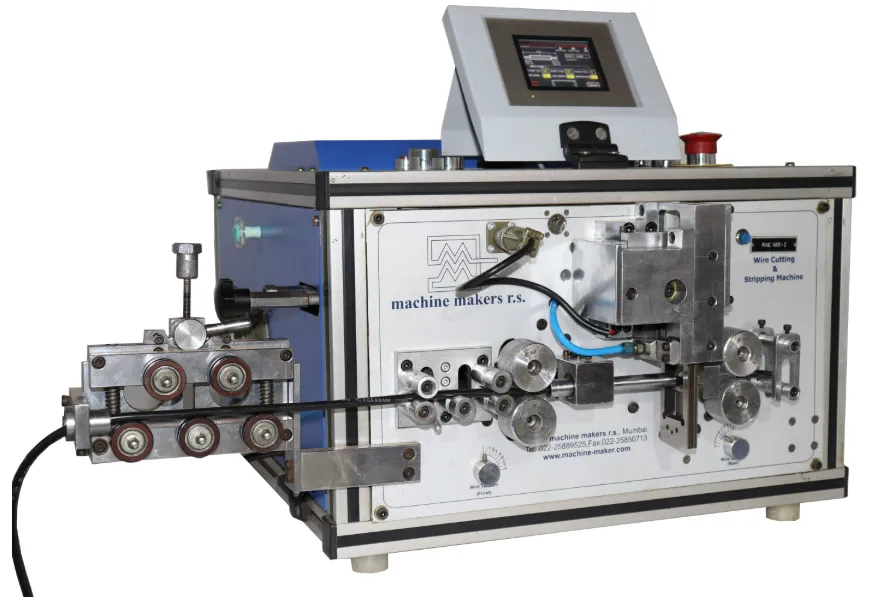

Wire cutting machines, often referred to as wire EDM (Electrical Discharge Machining) machines, operate on the principle of using electrical discharges to cut through materials. Unlike traditional cutting methods which employ blades or lasers, wire EDM utilizes a thin, electrically charged wire that acts as an electrode. As the wire moves through the material, it generates localized heat, effectively melting and vaporizing the material in its path.

The process is highly precise, allowing for intricate shapes and fine details that would be challenging to achieve with conventional cutting methods. Wire cutting machines are predominantly used for materials such as stainless steel, titanium, and various alloys, making them suitable for high-demand industries.

Types of Wire Cutting Machines

There are several types of wire cutting machines, each tailored to specific applications and requirements:

-

Standard Wire EDM Machines: These machines are designed for general-purpose cutting, featuring a fixed position for both the wire and the workpiece. They are suitable for producing a wide variety of shapes and sizes.

-

Rotary Wire EDM Machines: These systems include a rotating spindle that allows for continuous wire feed, enhancing cutting speed and efficiency. They are often used for bulk production where speed is essential.

-

2D and 3D Wire EDM Machines: While traditional machines are limited to 2D cutting, advanced 3D wire EDM machines can create complex geometries by moving the wire in three dimensions. This capability is invaluable for creating intricate components, especially in aerospace and automotive applications.

-

Fast Wire EDM Machines: These machines are engineered for high-speed operations, achieving rapid cutting rates without sacrificing precision. They are particularly useful in competitive manufacturing environments where time is critical.

Applications of Wire Cutting Machines

Wire cutting machines have a wide range of applications, owing to their versatility and precision. Some of the prominent uses include:

-

Aerospace Components: The aerospace industry requires parts that meet extremely tight tolerances. Wire EDM is used to manufacture turbines, fuel injectors, and other complex components that demand accuracy.

-

Medical Devices: Wire cutting is crucial in the production of medical instrumentation, such as surgical tools and implantable devices, where precision is paramount to patient safety.

-

Automotive Parts: From engine components to transmission parts, wire EDM machines are employed to create intricate shapes that traditional machining methods may not be able to achieve.

-

Molds and Dies: Wire cutting is often used to manufacture injection molds and stamping dies. The ability to create complex features ensures optimal performance and longevity of these tools.

The Future of Wire Cutting Machines

The wire cutting machine industry is poised for continued evolution, driven by advancements in technology and the increasing demand for precision manufacturing. Some key trends to watch include:

-

Automation and Smart Technologies: The integration of AI and machine learning into wire cutting machines is anticipated to enhance operational efficiency. Automated systems can analyze cutting conditions in real-time, optimizing performance and reducing human error.

-

Advanced Materials: As new materials such as composites and superalloys become more prevalent, wire cutting machines will need to adapt to handle these challenging materials without compromising precision.

-

Sustainability Initiatives: With rising environmental consciousness, manufacturers are focused on minimizing waste in the production process. Wire EDM is inherently efficient, but future developments may further reduce energy consumption and increase recyclability of materials.

-

Increased Customization: As industries require unique solutions, the ability to quickly switch between different wire types and configurations will become increasingly important. Future machines may be designed for rapid reconfiguration to meet specific project needs.

Conclusion

Wire cutting machines have transformed the landscape of manufacturing, offering unparalleled precision and versatility across various industries. As technology continues to advance, these machines will undoubtedly evolve, enabling manufacturers to meet the ever-increasing demands for high-quality, intricate components. The future of wire cutting is bright, with innovations on the horizon that promise to further enhance their capabilities and applications.