BlOG

Get a Free Quote

CNC Broaching: The High-Efficiency Cutting Solution for Complex Internal Geometries

Unlike conventional machining methods, CNC broaching delivers unparalleled accuracy in producing internal keyways, splines, and non-circular profiles.

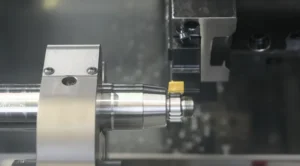

CNC Boring Machines: Precision Engineering for Industrial Applications

CNC boring machines are specialized machine tools designed for high-precision hole enlargement, finishing, and internal machining operations.

CNC Drilling: Precision and Efficiency in Modern Manufacturing

Computer Numerical Control (CNC) drilling has become a cornerstone in contemporary manufacturing, offering unparalleled precision, repeatability, and efficiency. This article explores the fundamentals of CNC drilling, its applications across various industries, the tangible benefits it provides, and the challenges it faces.

Aluminum Die Casting: Precision Engineering for Mass Production

The aluminum die casting industry has evolved into a sophisticated manufacturing sector capable of producing complex, high-tolerance components at remarkable speeds. Modern cold chamber die casting machines now routinely operate at clamping forces ranging from 250 to 4,000 tons, with shot weights varying from a few grams to over 50 kg.

Steel Laser Cutting: Precision and Efficiency in Modern Metal Fabrication

The evolution of steel laser cutting has revolutionized metal manufacturing, offering unparalleled precision, speed, and versatility across industries. Modern fiber laser systems can process carbon steel up to 30 mm thick with cutting tolerances of ±0.1 mm, while maintaining kerf widths as narrow as 0.2 mm.

Precision Tooling: The Foundation of Modern Manufacturing Accuracy

In today’s manufacturing landscape, precision tooling has become the critical differentiator between adequate and exceptional part quality. The industry has seen tooling tolerances shrink from ±0.1mm to ±0.005mm in just the past decade, with leading-edge applications now demanding ±0.001mm consistency in medical and aerospace components.

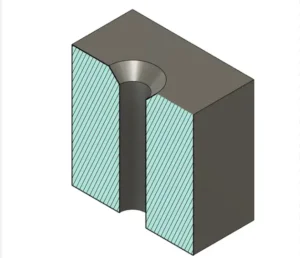

Countersunk Holes: Engineering Precision for Flush Fastening Solutions

In mechanical design and manufacturing, countersunk holes represent a critical fastener solution where flush surface mounting is required. These conical recesses allow screw heads to sit perfectly level with or below the material surface, eliminating protrusions that could interfere with assembly or create safety hazards.

Black Oxide Coating: Process, Benefits, and Applications

Black oxide coating, also known as blackening or black oxide treatment, is a widely used surface finishing technique that enhances the aesthetic and functional properties of metal parts.

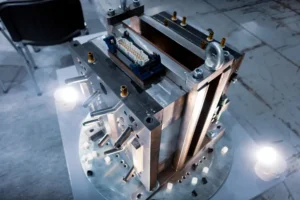

Understanding Injection Molding: A Comprehensive Overview

Injection molding stands as one of the most efficient and widely employed manufacturing processes today, revolutionizing the production of various plastic components and products. This article offers an in-depth exploration of injection molding, delving into its mechanisms, materials, advantages, applications, and future trends.

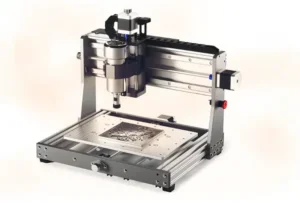

Budget CNC Machines: A Comprehensive Guide for 2025

As the need for precision machining continues to rise across various industries, budget CNC (Computer Numerical Control) machines have gained significant traction. Whether you’re a hobbyist, a small business owner, or an educational institution, investing in a budget-friendly CNC machine can be a game-changer.

Woodworking CNC Machines: Precision and Versatility in Modern Woodcraft

The woodworking industry has seen a dramatic transformation with the integration of CNC technology, enabling craftsmen and manufacturers to achieve levels of precision and efficiency previously unimaginable with traditional tools.

The Best CNC Milling Machines: Precision Powerhouses for Modern Manufacturing

In today’s competitive manufacturing landscape, CNC milling machines represent the backbone of precision machining, offering unmatched accuracy, speed, and versatility. From aerospace components to medical implants, the right CNC mill can dramatically impact productivity and part quality.