01

Continuous R&D Investment

Sustained research drives innovation, ensuring CNC auto parts manufacturing stays ahead of industry trends

02

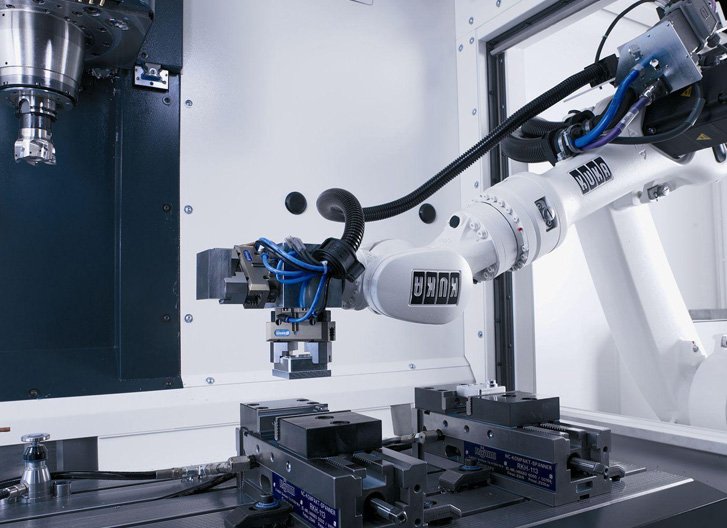

Advanced Production Technology

Cutting-edge manufacturing enhances precision and efficiency, optimizing CNC auto parts production

03

Strict Quality Control System

Rigorous quality control ensures every CNC auto part meets the highest standards with absolute precision

Our Manufacturing Services

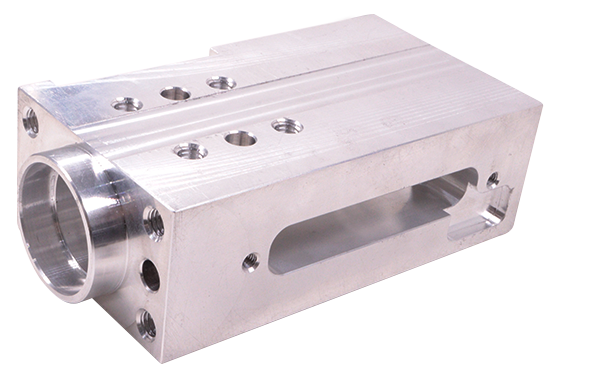

CNC Machining

Milling,turning and post-processing

- Tolerances down to ±.0.005 mm

- High-precision processing machinery and equipment (five-axis processing)

Forging

High-strength metal shaping

Ultra-strong grain structure

85% material efficiency

- Batches of 1-10K unit

- Mould design, development and manufacturing

Casting

Complex shapes, single mold

- Zero-assembly geometries

- Alloy flexibility

100+ metal/alloy options available

- Mould design, development and manufacturing

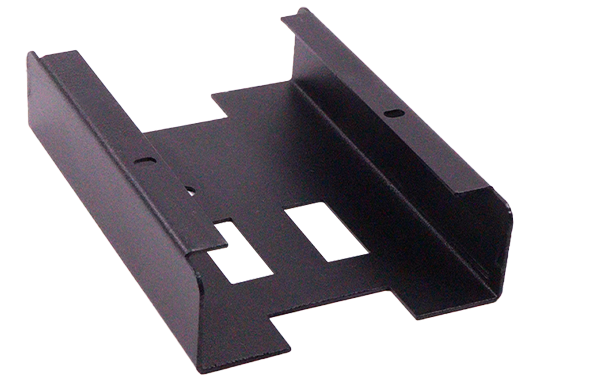

Stamping

Fast precision sheet forming

- ±0.005mm

mm repeatability - 1,500+ parts/hour

- Zero downtime with automated feeding

Product display

Quality Parts for Various Industries

ABOUT US

Deshengrui Machinery Co., Ltd.

Deshengrui Machinery was founded in 2011 and started to provide products for Automotive Industry, Telecommunication Equipment, Automatic Industrial Equipment, Water Treatment Equipment, Lighting Industry etc.

We have rich experience in machining many kinds of materials, such as Aluminum AL6061/7075, Stainless steel 303/304/316, Brass, Steel (C45/Q235/Q345/4140/SPCC/DC01), plastic (POM/NYLON), etc. We can also provide forged parts, stamping parts, iron casting parts, steel casting parts and die casting parts.

Service First,Quality Assurance

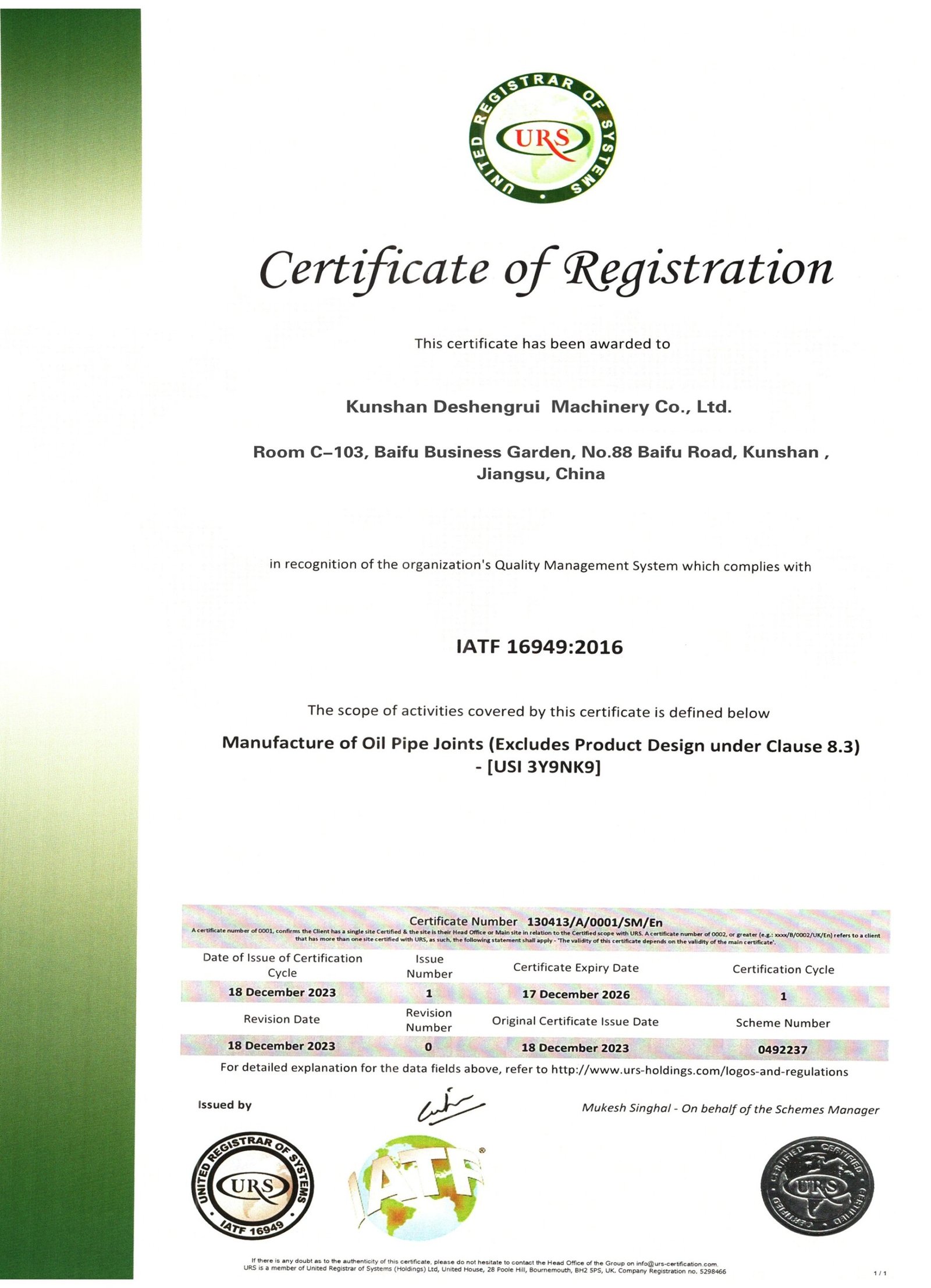

Imagine a world where your prototypes accelerate on our 5-axis CNC lines, while your high-volume runs scale seamlessly through our ISO 9001/IATF-certified global partners — all under your control from a single dashboard.

Free sample

We could provide you with free samples! if the sample total value less than $50.

Competitive price

We offer competitive prices for the products you need, and we also guarantee the quality for you.

Quick response

Our sales staffs will communicate with you as soon as we received your inquiry.

Guaranteed quality

We will carry out strict quality inspection on your products, to ensure that each product perfectly meets your requirements

Timely delivery

We always follow the delivery date strictly, and deliver the product to you at the most suitable time.

Safe and Trustworthy

We’ve been tested and certified by many third-party agencies, and you can always check them out.

Clients Reviews

Michael Zhang

The quality of the parts has really improved our production line. We’ve noticed fewer issues and increased efficiency.

Jessica Liu

I appreciate their attention to detail in every order. It shows they truly care about the quality of their work.

John Smith

The precision of their CNC parts is unmatched! Every piece fits perfectly, which helps our production run smoothly.

Kevin Hu

From design to delivery, they are always professional and make the entire process seamless.

Michelle Fan

I can always count on them for high-quality CNC machining. They are my go-to source for all precision parts.

Robert Johnson

I appreciate their attention to detail in every order. It shows they truly care about the quality of their work.

BLOG

CNC Broaching: The High-Efficiency Cutting Solution for Complex Internal Geometries

Unlike conventional machining methods, CNC broaching delivers unparalleled accuracy in producing internal keyways, splines, and non-circular profiles.

CNC Boring Machines: Precision Engineering for Industrial Applications

CNC boring machines are specialized machine tools designed for high-precision hole enlargement, finishing, and internal machining operations.

CNC Drilling: Precision and Efficiency in Modern Manufacturing

Computer Numerical Control (CNC) drilling has become a cornerstone in contemporary manufacturing, offering unparalleled precision, repeatability, and efficiency. This article explores the fundamentals of CNC drilling, its applications across various industries, the tangible benefits it provides, and the challenges it faces.