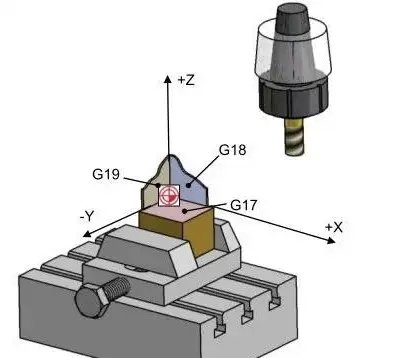

3-axis machining:

In 3-axis machining, processing is performed using linear feed axes X, Y, and Z. Characteristics include: the cutting tool direction remains constant throughout the entire cutting path. Real-time perfect cutting conditions at the tool tip are not achievable.

5-axis machining:

5-axis machining involves linear interpolation motion along any five axes of feed axes X, Y, Z, and rotational axes A, B, C around X, Y, Z. Siemens’ motion transformation instruction TRAORI effectively supports 5-axis transformations.

Summary:

In CNC machining centers, 3-axis and 5-axis refer to the number of controllable axes on the machine.

Specifically, the differences are as follows: (3-axis) typically refers to the X, Y, and Z axes, enabling linear motion to produce 2D or simple 3D shapes. (5-axis) In addition to the X, Y, and Z axes, there are two additional rotational axes, usually A and C axes. Through the coordination of these five axes, complex 3D shapes can be machined. Compared to 3-axis machining centers, 5-axis machining centers can produce more complex parts with higher efficiency and precision.