A CNC (Computer Numerical Control) system represents the digital brain and nervous system of modern automated manufacturing equipment. This sophisticated control architecture transforms digital design specifications into precise physical movements of machine tools with micron-level accuracy.

Core Components:

Core Components:

- Central Processing Unit (CPU):

- Industrial-grade processor (typically 32-bit or 64-bit)

- Real-time operating system (RTOS) for deterministic performance

- Processing speeds ranging from 1-4 GHz in modern systems

- Motion Controller:

- Manages up to 9 axes of simultaneous interpolation

- Controls servo/stepper motors with pulse frequencies exceeding 4 MHz

- Maintains positioning accuracy within ±0.0001″ (±2.5μm)

- Input/Output (I/O) System:

- Digital I/O channels (typically 16-64 points)

- Analog inputs for sensor monitoring

- Fieldbus interfaces (EtherCAT, PROFINET, etc.)

Software Architecture:

- Machine Control Software:

- G-code interpreter (ISO 6983 standard)

- PLC functionality (IEC 61131-3 compliant)

- Look-ahead processing (50-1000 blocks)

- Human-Machine Interface (HMI):

- Touchscreen displays (7″-24″ industrial panels)

- Virtual control panels

- 3D toolpath visualization

Positioning Systems:

- Feedback Devices:

- Rotary encoders (20-bit resolution)

- Linear scales (0.1μm resolution)

- Laser interferometers for calibration

- Drive Systems:

- AC servo drives (1-50kW)

- Stepper systems (NEMA 17-42 frames)

- Linear motor configurations

Communication Protocols:

- Network Interfaces:

- Ethernet (100Mbps-1Gbps)

- RS-232/422 legacy ports

- Wireless connectivity options

- Data Transfer Standards:

- DNC (Direct Numerical Control)

- MTConnect for machine monitoring

- OPC UA for Industry 4.0 integration

Control Functions:

- Axis Control:

- Coordinated multi-axis motion

- Jerk-limited acceleration profiles

- Backlash compensation algorithms

- Spindle Management:

- Speed control (50-30,000 RPM)

- Orientation positioning (±0.001°)

- Load monitoring (0-150% capacity)

- Tool Management:

- Automatic tool changers (ATC)

- Tool length/wear compensation

- Life monitoring systems

Safety Systems:

- Hardware Protections:

- Emergency stop circuits (Category 3/PL e)

- Safe torque off (STO) functionality

- Over-travel limit switches

- Software Protections:

- Collision avoidance algorithms

- Thermal overload monitoring

- Vibration detection systems

Programming Capabilities:

- Standard Programming:

- G-code (ISO standard)

- M-code (machine functions)

- Macro programming (parametric)

- Advanced Features:

- Conversational programming

- CAD/CAM direct interfaces

- Simulation modes

System Variants:

- Standalone Controllers:

- Dedicated CNC units (Fanuc, Siemens, etc.)

- Typical memory: 1-256MB

- Storage: CompactFlash/SD cards

- PC-Based Systems:

- Industrial PCs with motion cards

- Windows/Linux real-time extensions

- Cloud connectivity options

Performance Specifications:

- Block processing time: 0.1-5ms

- Minimum increment: 0.00001″ (0.1μm)

- Maximum feedrate: 1,500 IPM (38 m/min)

- Synchronization accuracy: <1μs

Industry Applications:

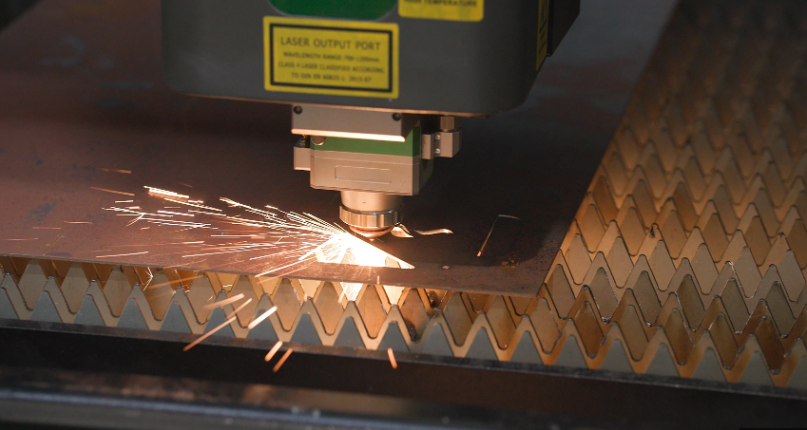

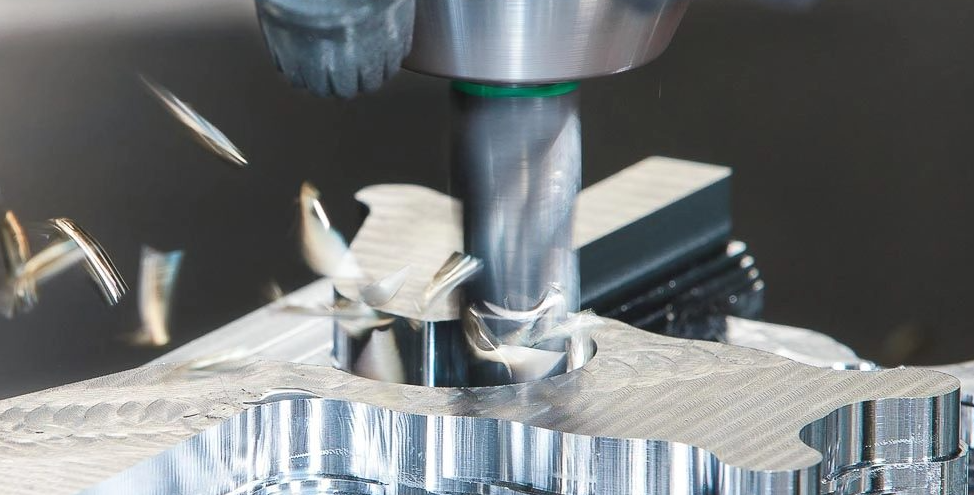

- Metal Cutting:

- Mills, lathes, grinders

- EDM machines

- Laser/waterjet cutters

- Other Manufacturing:

- Woodworking routers

- 3D printers

- Composite material machines

Maintenance Features:

- Predictive maintenance algorithms

- Vibration analysis capabilities

- Remote diagnostics access

- Firmware update mechanisms

Emerging Technologies:

- AI-based adaptive control

- Digital twin integration

- Edge computing applications

- Quantum computing interfaces

CNC systems continue evolving with enhanced connectivity, smarter control algorithms, and tighter integration with manufacturing execution systems (MES), maintaining their critical role in Industry 4.0 environments while supporting increasingly complex machining operations.