Introduction to CNC Router Technology

A CNC router is an automated cutting machine that utilizes computer numerical control to precisely shape various materials. Unlike manual machining tools, these systems follow digital instructions to execute complex cutting operations with minimal human intervention. The technology has revolutionized manufacturing processes across multiple industries by combining digital precision with mechanical cutting capabilities.

Historical Development

Historical Development

The evolution of CNC routers traces back to the 1940s when numerical control systems were first developed for military applications. Early models in the 1970s used punch tape programming, while modern systems employ sophisticated CAD/CAM software integration. The transition from stepper motors to servo motors in the 1990s significantly improved accuracy and speed capabilities.

Core Mechanical Components

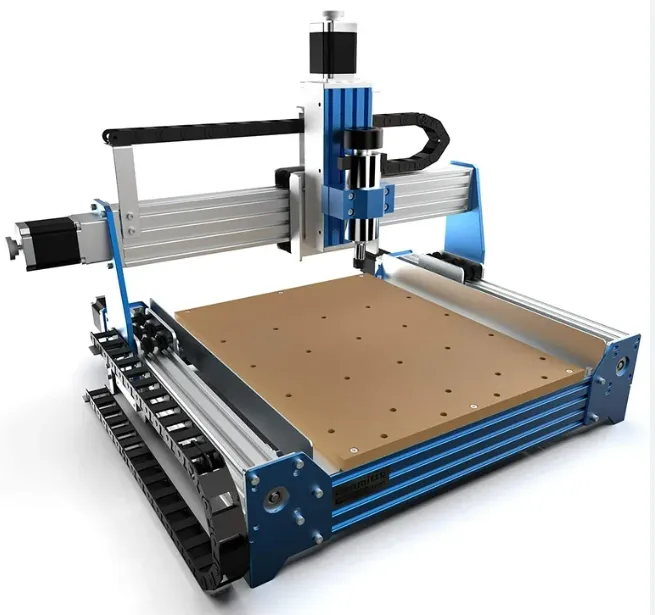

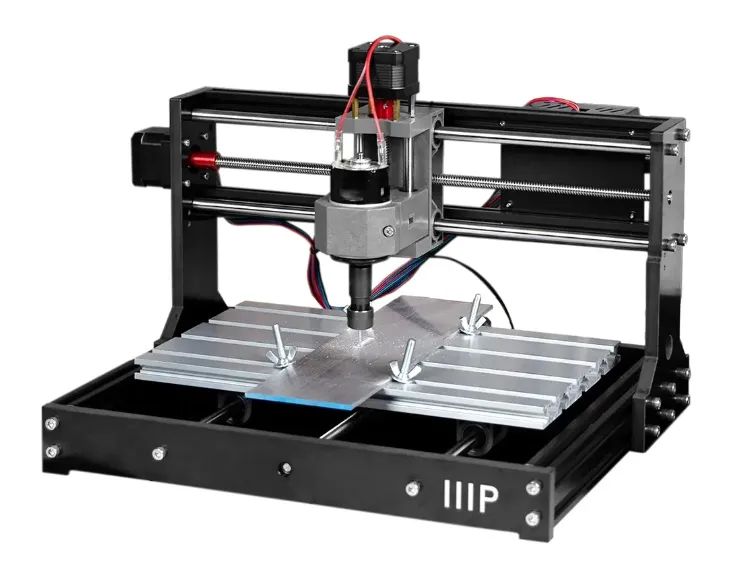

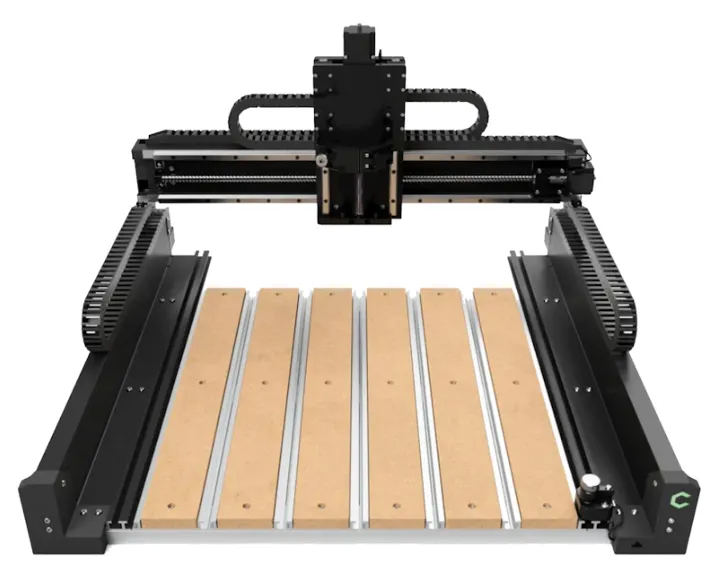

The structural framework of a CNC router consists of:

- A rigid base frame typically constructed from welded steel or aluminum extrusions

- Moving gantry systems that traverse along precision-ground linear rails

- Ball screw or rack-and-pinion drive mechanisms for axis movement

- Anti-backlash nut assemblies that maintain positioning accuracy

- Heavy-duty work tables with T-slots or vacuum hold-down systems

Electronics and Control Systems

Modern CNC routers incorporate:

- Industrial-grade motion controllers with DSP processing

- High-performance servo drives with 20-bit encoders

- Spindle vector drives capable of maintaining constant torque

- Integrated PLCs for auxiliary function control

- Touchscreen HMI interfaces with real-time monitoring

Cutting Tool Technology

Router spindles feature:

- Air-cooled or liquid-cooled designs (1.5-30HP)

- ER collet chucks for tool holding

- Automatic tool changers with 8-24 station carousels

- HSK tool interface systems for high-speed applications

- Laser-assisted tool measurement systems

Software Architecture

The operating system includes:

- CAD/CAM software packages for design conversion

- Post-processors for machine-specific G-code generation

- Simulation modules for toolpath verification

- Nesting algorithms for material optimization

- DNC systems for large program management

Material Processing Capabilities

CNC routers handle diverse materials:

- Wood products: Hardwoods, MDF, plywood (cut speeds 10-30m/min)

- Plastics: Acrylic, PVC, polycarbonate (feed rates 5-15m/min)

- Non-ferrous metals: Aluminum, brass (0.5-5m/min cutting speeds)

- Composites: Carbon fiber, fiberglass (specialized tooling required)

Precision and Accuracy Specifications

Performance metrics include:

- Positioning accuracy: ±0.01mm to ±0.05mm

- Repeatability: ±0.005mm to ±0.02mm

- Minimum incremental movement: 0.001mm

- Surface finish quality: Ra 0.8-3.2μm achievable

Industrial Applications

Major usage sectors comprise:

- Furniture manufacturing: Cabinet door production, decorative carving

- Sign making: Dimensional letter fabrication, LED channel routing

- Aerospace: Lightweight component machining

- Automotive: Interior trim production, prototype development

- Musical instruments: Precision body shaping, inlay work

Safety Systems and Features

Critical safety components:

- Emergency stop circuits with redundant monitoring

- Axis limit switches with soft/hard stop functionality

- Spindle overload protection

- Enclosure interlocks

- Chip containment systems

Maintenance Requirements

Scheduled upkeep involves:

- Linear guide lubrication (automatic or manual)

- Ball screw backlash inspection

- Spindle bearing replacement cycles

- Cooling system maintenance

- Controller firmware updates

Emerging Technological Developments

Current innovations include:

- Hybrid additive-subtractive systems

- AI-based tool wear prediction

- Augmented reality setup assistance

- Cloud-based machine monitoring

- Advanced vibration damping systems

Economic Considerations

Cost factors encompass:

- Machine acquisition (entry-level to industrial-grade)

- Tooling and workholding investments

- Maintenance and operational expenses

- Operator training requirements

- ROI calculations based on production throughput

Environmental Impact

Sustainability aspects:

- Energy-efficient spindle designs

- Chip recycling systems

- Low-emission cutting processes

- Noise reduction technologies

- Coolant filtration and reuse

Future Outlook

Anticipated advancements:

- Increased adoption of 5-axis technology

- Enhanced material handling automation

- Improved cutting tool materials

- Tighter integration with Industry 4.0 systems

- Expanded material compatibility

This comprehensive examination of CNC router technology demonstrates its critical role in modern manufacturing, offering unparalleled precision and efficiency in material processing applications across diverse industries. The continuous evolution of these systems ensures their ongoing relevance in an increasingly automated production landscape.