The cantilever pin is a highly specialized non-standard mechanical component designed to support loads while allowing rotational or linear movement in various applications. Unlike standard fasteners such as bolts or dowel pins, cantilever pins are engineered to withstand shear, bending, and torsional forces, making them essential in high-load-bearing mechanical systems.

Due to their unique role, these pins require precise design, material selection, and manufacturing processes to ensure durability and performance. This article provides a detailed exploration of cantilever pins, covering their structural characteristics, applications, engineering challenges, and future advancements.

Structural Design and Material Selection

Geometrical Features and Variants

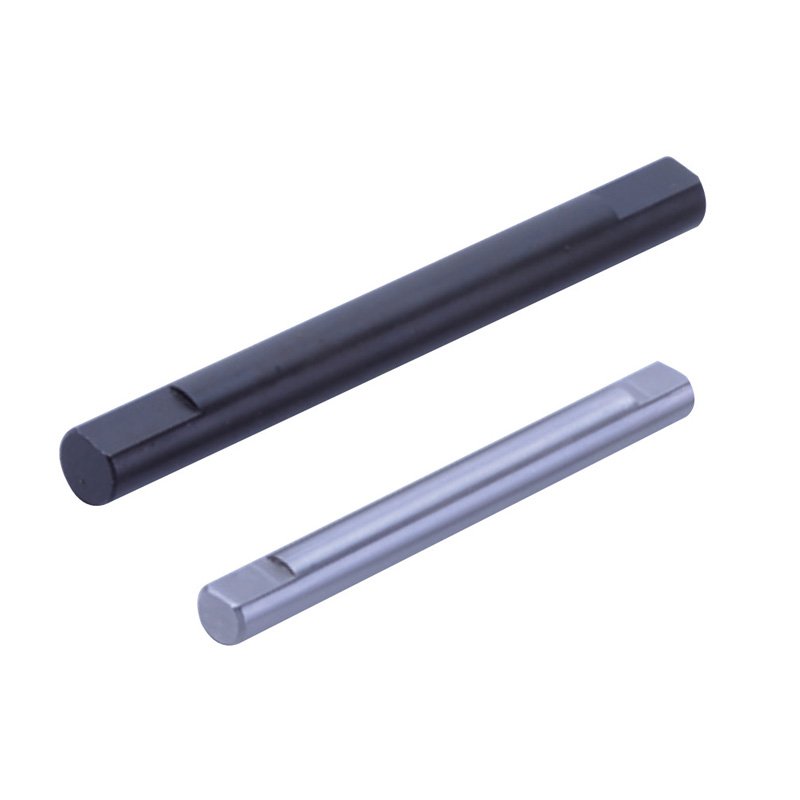

Cantilever pins are typically cylindrical, but their design can vary significantly based on their intended use. Some common features include:

- Threaded Ends: For secure attachment in high-vibration environments.

- Grooves or Retention Features: To accommodate circlips, retaining rings, or other locking mechanisms.

- Tapered Sections: For applications requiring self-locking functionality.

- Holes for Cotter Pins: Used in automotive and heavy machinery applications for additional security.

Material Considerations

Selecting the right material is critical for ensuring mechanical integrity under dynamic loads. The most commonly used materials include:

-

Alloy Steels (AISI 4140, 4340):

- High tensile strength and toughness

- Suitable for applications requiring resistance to fatigue and impact

-

Stainless Steels (316L, 17-4 PH):

- Excellent corrosion resistance

- Used in aerospace, medical devices, and marine environments

-

Titanium Alloys (Grade 5 Ti-6Al-4V):

- High strength-to-weight ratio

- Ideal for aerospace and high-performance applications

-

Brass and Bronze:

- Low friction and good wear resistance

- Often used in bearings and sliding mechanisms

Surface Treatments and Coatings

To improve durability and performance, cantilever pins often undergo surface treatments such as:

- Nitriding: Enhances surface hardness and wear resistance.

- Black Oxide Coating: Provides mild corrosion resistance and reduces glare.

- Zinc or Nickel Plating: Commonly used for enhanced corrosion resistance in industrial applications.

- PTFE Coating: Reduces friction for smoother operation in mechanical assemblies.

Applications Across Industries

Cantilever pins are widely used in industries where precise load management and controlled motion are required.

1. Automotive Engineering

Cantilever pins are critical in suspension and drivetrain systems, where they serve functions such as:

- Pivot points for control arms and linkages.

- Brake caliper guide pins in disc brake systems.

- Gear shift and clutch linkages requiring rotational motion.

2. Aerospace and Defense

In aerospace applications, these pins must meet stringent material and precision standards:

- Aircraft landing gear hinge pins, exposed to extreme loads during takeoff and landing.

- Helicopter rotor connection points requiring high fatigue resistance.

- Weapon system mounting pins, ensuring secure attachment under dynamic conditions.

3. Industrial Machinery and Heavy Equipment

Heavy-duty machinery requires robust cantilever pins in components such as:

- Conveyor belt tensioning systems, where the pin serves as a pivot for belt adjustments.

- Robotic arm joints, allowing precise movement while bearing significant loads.

- Agricultural equipment, where they serve as pivoting connectors in hydraulic systems.

4. Medical Devices

Cantilever pins are also used in precision medical equipment, such as:

- Adjustable orthopedic instruments, where high precision is critical for patient safety.

- Surgical robots requiring low-friction pivot points for articulated arms.

Engineering Challenges and Failure Considerations

Despite their simple appearance, cantilever pins are subjected to complex stresses. The following engineering challenges must be addressed:

1. Fatigue and Stress Concentration

Repeated cyclic loading can lead to microcrack formation and fatigue failure. To mitigate this, engineers conduct:

- Finite Element Analysis (FEA): Predicts stress distribution and potential failure points.

- Shot Peening: Induces surface compressive stress to improve fatigue resistance.

2. Wear and Corrosion Resistance

In environments with high friction or exposure to chemicals, wear-resistant coatings or self-lubricating materials (e.g., PTFE coatings) are essential to extend the component’s lifespan.

3. Dimensional Tolerances and Fitment

For applications requiring high precision, tolerances as tight as ±0.01 mm may be necessary. Advanced CNC machining and honing processes ensure that the pin maintains proper fitment.

Manufacturing Process and Quality Control

The production of cantilever pins involves several critical steps to ensure mechanical integrity:

- CNC Machining: High-precision turning and milling ensure dimensional accuracy.

- Heat Treatment: Quenching and tempering enhance mechanical properties.

- Grinding and Polishing: Ensures a smooth surface finish and reduces friction.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection detect micro-defects.

Case Study: Aerospace Cantilever Pins

A leading aerospace manufacturer recently redesigned its landing gear hinge pin using 17-4 PH stainless steel, replacing a previously used titanium alloy. Finite element analysis revealed that the new material improved fatigue resistance by 22% while maintaining weight constraints. This real-world case highlights the importance of material selection in high-performance applications.

Future Trends and Innovations

1. Advanced Materials

Research into nanostructured alloys and composite materials aims to improve strength while reducing weight. Titanium-aluminum alloys are being explored for their high fatigue resistance.

2. Additive Manufacturing (3D Printing)

The use of metal additive manufacturing allows for complex geometries and lightweight structures, reducing material waste.

3. Smart Coatings

New coating technologies incorporating self-healing polymers and embedded sensors can provide real-time data on pin wear and structural integrity.

4. AI-Driven Predictive Maintenance

With the rise of machine learning and AI, predictive maintenance systems can analyze load history and environmental conditions to estimate component lifespan, reducing unplanned downtime.

Conclusion

Cantilever pins, though small, play a vital role in mechanical assemblies across multiple industries. Their ability to withstand high loads, provide rotational movement, and maintain precise fitment makes them indispensable in modern engineering.

Advancements in materials, surface treatments, and manufacturing techniques continue to push the boundaries of performance, ensuring that these components remain reliable in high-stress, high-precision applications. Whether in aerospace, automotive, or industrial machinery, the future of cantilever pins lies in enhanced durability, reduced weight, and smarter integration into predictive maintenance systems.

By understanding the design principles, challenges, and innovations surrounding these critical components, engineers can ensure optimal performance, safety, and longevity in their respective applications.