Pillow block bearings, often referred to as plummer block bearings, are essential components in various mechanical and manufacturing systems. They provide support for rotating shafts while accommodating misalignment and minimizing friction, thereby ensuring smooth operation in machinery. In this article, we’ll delve into the definition, types, applications, advantages, and maintenance of pillow block bearings, providing a thorough understanding of their significance in the world of engineering.

What Are Pillow Block Bearings?

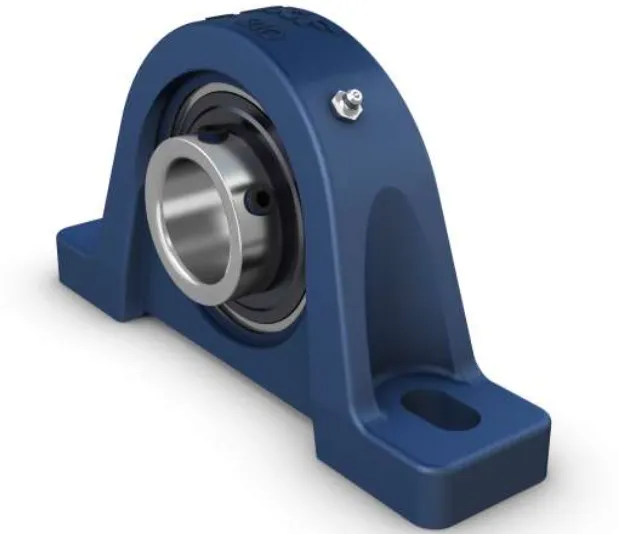

Pillow block bearings are mounted bearings housed in a sleek block or casing, which offers structural support to rotating machinery. The design allows them to be bolted onto a flat surface, positioning the rotating shaft within the bearing. The main objective of a pillow block bearing is to stabilize the shaft while permitting its rotation, thus reducing wear and tear on both the bearing and the shaft itself.

The bearing itself can be either a ball bearing or a roller bearing, depending on the specific application requirements. With their robust construction, pillow block bearings can handle substantial loads and enable smooth motion in various equipment.

Types of Pillow Block Bearings

Pillow block bearings can be categorized based on their design and material. The most common types include:

-

Ball Pillow Block Bearings: These are designed with ball elements to manage radial loads effectively while allowing for rotational movement. They are well-suited for applications requiring precise motion and minimal friction.

-

Roller Pillow Block Bearings: Utilizing cylindrical rollers, these bearings are designed to handle high radial loads and impacts. They are often used in heavy-duty applications where significant load capacity is required.

-

Split Pillow Block Bearings: These bearings consist of two separate halves that can be installed around the shaft. This design is beneficial when shaft removal is challenging, allowing for easier maintenance without disconnecting the entire assembly.

-

Solid Pillow Block Bearings: Constructed from a single piece of material, these bearings offer increased durability and are commonly used in applications with infrequent bearing replacements.

-

Self-Aligning Pillow Block Bearings: These bearings feature a spherical outer surface that can accommodate slight misalignments in the shaft’s positioning, making them ideal for applications where alignment might shift during operation.

Applications of Pillow Block Bearings

Pillow block bearings are versatile components used in a wide range of industries and applications, including:

-

Automotive Industry: They are used in various vehicles, including cars and trucks, to support rotating shafts in engines and transmissions.

-

Agricultural Equipment: In tractors and harvesters, pillow block bearings help maintain the rotation of axles and other moving parts.

-

Conveyor Systems: Used extensively in material handling, pillow block bearings support conveyor belts and ensure smooth movement of goods.

-

Manufacturing Machinery: These bearings are pivotal in machines that operate with rotating parts, enhancing productivity by reducing friction and wear.

-

HVAC Systems: Pillow block bearings are employed in blowers and compressors to support rotating shafts, crucial for efficient airflow and operation.

Advantages of Pillow Block Bearings

Pillow block bearings offer several key benefits:

-

Ease of Installation: Their design allows for straightforward mounting and replacement, minimizing downtime during maintenance.

-

Load Support: They can support high radial loads, making them suitable for various heavy-duty applications.

-

Alignment Compensation: With self-aligning capabilities, pillow block bearings can accommodate misalignment, reducing wear on the shaft and increasing the lifespan of both the bearing and machinery.

-

Reduced Friction: The smooth operation of pillow block bearings minimizes friction, enhancing the efficiency of rotating components.

-

Durability: Made from high-quality materials, pillow block bearings are designed to withstand harsh operating conditions, providing reliability over extended periods.

Maintenance Tips for Pillow Block Bearings

To ensure optimal performance and longevity of pillow block bearings, regular maintenance is essential. Here are some tips:

-

Routine Inspections: Regularly check for signs of wear, lubrication failure, or misalignment. Early detection of issues can prevent costly repairs.

-

Proper Lubrication: Ensure that bearings are adequately lubricated according to the manufacturer’s specifications. Insufficient lubrication can lead to overheating and bearing failure.

-

Monitoring Temperature: Keep an eye on the operating temperature. Excessive heat may indicate underlying issues, such as lack of lubrication or misalignment.

-

Tightening Bolts: Periodically inspect and tighten the mounting bolts to ensure secure fastening and maintain alignment.

-

Replacement Plans: Have a strategy for timely replacement of old or worn-out pillow block bearings to prevent unexpected machinery failure.

Conclusion

Pillow block bearings are a critical component in various machinery and equipment across multiple industries. Their robust design, ability to accommodate misalignment, and ease of maintenance make them indispensable in ensuring smooth and efficient operations. By understanding the types, applications, advantages, and maintenance practices associated with pillow block bearings, industries can enhance their operational efficiency and prolong the life of their machinery. As technology continues to advance, the evolution of pillow block bearings will undoubtedly contribute to the growing demands of modern manufacturing and engineering.