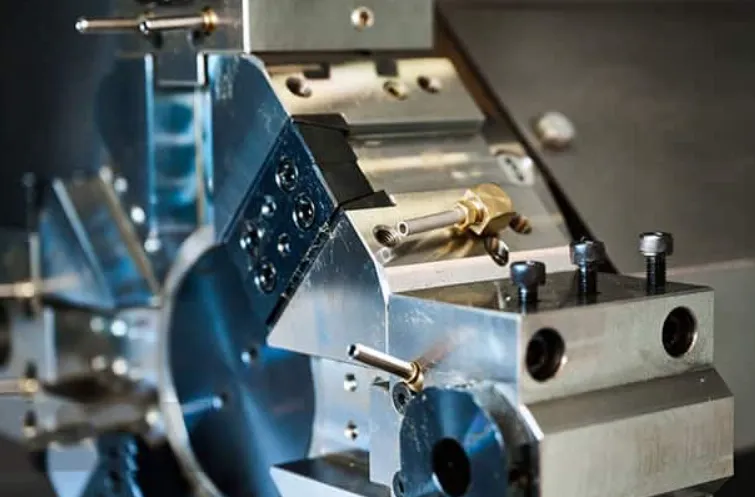

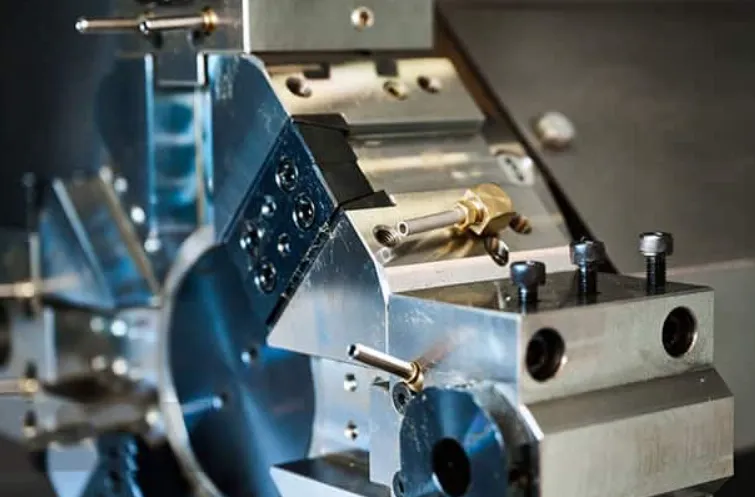

Turret lathes remain indispensable in modern manufacturing, offering unmatched efficiency for medium-to-high volume production of precision turned parts. Unlike conventional engine lathes, these machines feature a hexagonal turret capable of holding 6-12 tools simultaneously, reducing changeover time by up to 80% compared to manual tooling systems. Current models like the Haas ST-30Y demonstrate this advantage practically, completing complex part geometries in a single chucking through sequential operations including turning, facing, drilling, and threading – all with positioning repeatability of ±0.005mm.

The economic impact becomes clear when examining production metrics: A standard 2-axis turret lathe typically achieves 25-35% higher output than conventional lathes when machining brass fittings, with cycle times reduced from 8.5 minutes to 6.2 minutes per part. This efficiency stems from the turret’s ability to pre-stage tools, eliminating the 12-18 second tool change delays common in manual operations. Modern CNC turret lathes like the Mazak Quick Turn 250MSY push these boundaries further, incorporating live tooling for milling operations that reduce secondary processing by an additional 40%.

The economic impact becomes clear when examining production metrics: A standard 2-axis turret lathe typically achieves 25-35% higher output than conventional lathes when machining brass fittings, with cycle times reduced from 8.5 minutes to 6.2 minutes per part. This efficiency stems from the turret’s ability to pre-stage tools, eliminating the 12-18 second tool change delays common in manual operations. Modern CNC turret lathes like the Mazak Quick Turn 250MSY push these boundaries further, incorporating live tooling for milling operations that reduce secondary processing by an additional 40%.

Material-specific innovations have expanded turret lathe capabilities dramatically. For tough alloys like Inconel 718, builders now integrate high-pressure coolant systems (up to 1000psi) directly through rotating turret stations, extending tool life by 300% when machining at surface speeds of 60-80m/min. Swiss-type turret lathes take precision further, with Citizen’s L32 XII model demonstrating 0.0002″ (5μm) diameter tolerances on medical bone screws made from Ti-6Al-4V ELI. The machine’s guide bushing design and 12,000rpm main spindle maintain these tolerances across lots of 50,000+ components.

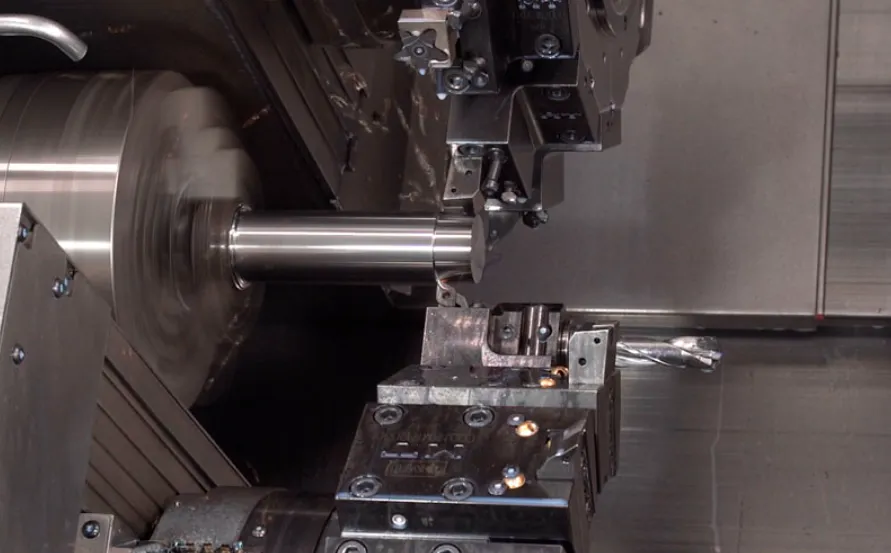

Automation integration has transformed turret lathe productivity. The Okuma GENOS L300-MYW exemplifies this evolution, combining a 10-station turret with robotic loading to achieve lights-out production of aluminum hydraulic components at 98 parts/hour. Real-world data from automotive suppliers shows these systems reduce labor costs by 60% while maintaining 99.2% first-pass yield rates on diameter tolerances of ±0.01mm.

Emerging smart technologies address traditional turret lathe limitations. Thermal compensation systems now automatically adjust for spindle growth during extended runs, maintaining positional accuracy within 2μm despite temperature fluctuations. On Mori Seiki’s NTX1000, this technology works in tandem with vibration-dampening turret mounts to enable fine finishing cuts (0.4μm Ra) on hardened steel dies (HRC62) at 1,800rpm – a task previously requiring separate grinding operations.

The future points toward even greater integration. Newer models like the DMG MORI NLX 2500 combine traditional turret strengths with additive manufacturing capabilities, allowing deposition of wear-resistant coatings during the turning process itself. This hybrid approach has shown particular promise in oil/gas applications, where Inconel 625 clad valves demonstrate 8x longer service life than conventionally machined components. As Industry 4.0 connectivity becomes standard, expect turret lathes to evolve from standalone workhorses into fully networked manufacturing nodes capable of self-optimizing tool paths based on real-time cutting data.