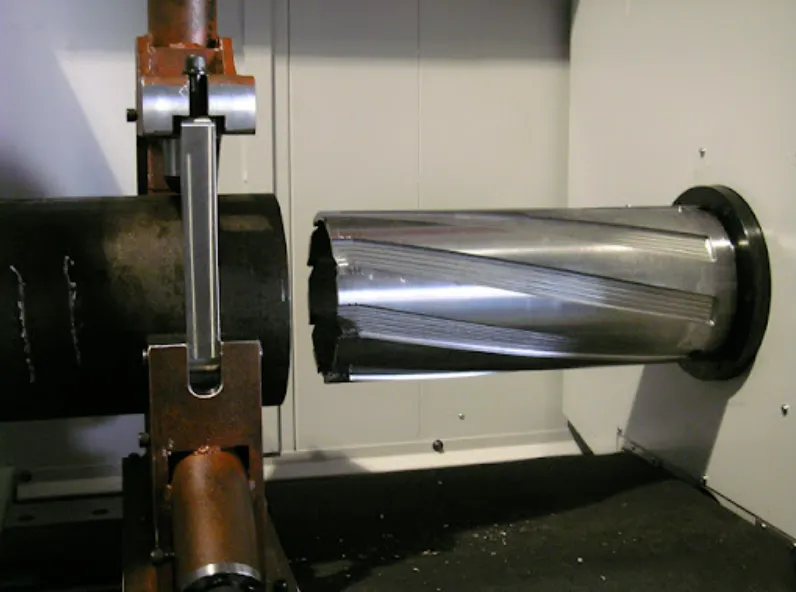

Trepanning machining is a specialized process used in industrial manufacturing to create large-diameter holes in various materials. This technique distinguishes itself from conventional drilling by removing a cylindrical core from the workpiece instead of grinding down the entire diameter into chips. As a result, trepanning is especially valuable in applications requiring precision, efficiency, and the retention of solid material.

The Definition and Process of Trepanning

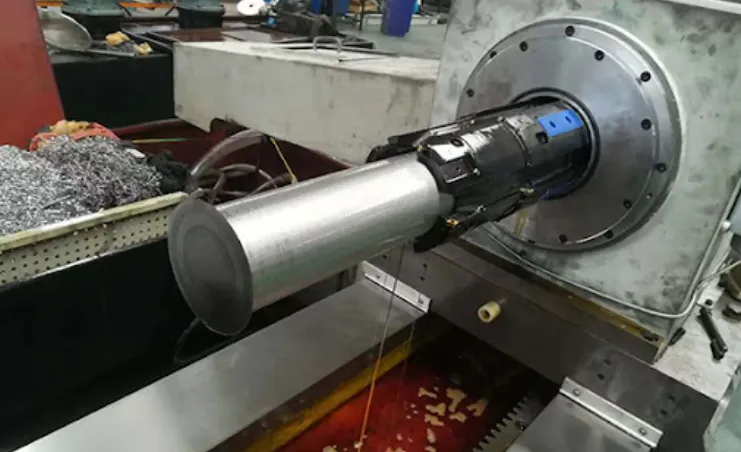

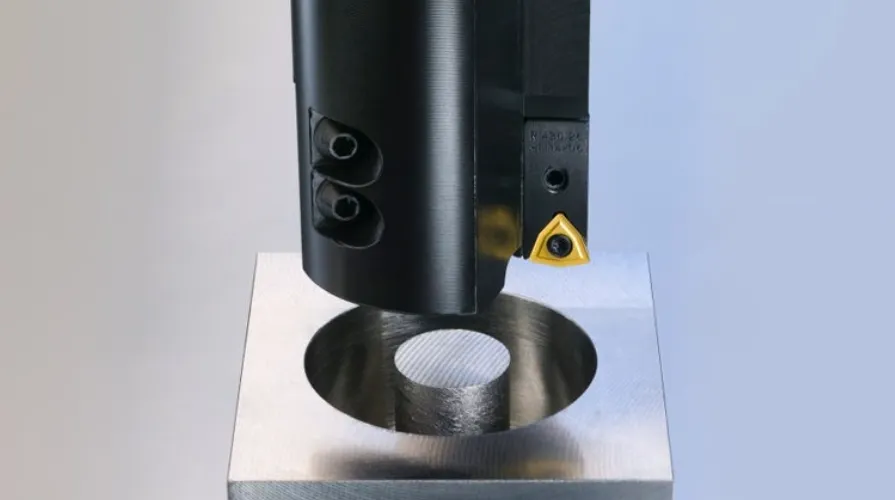

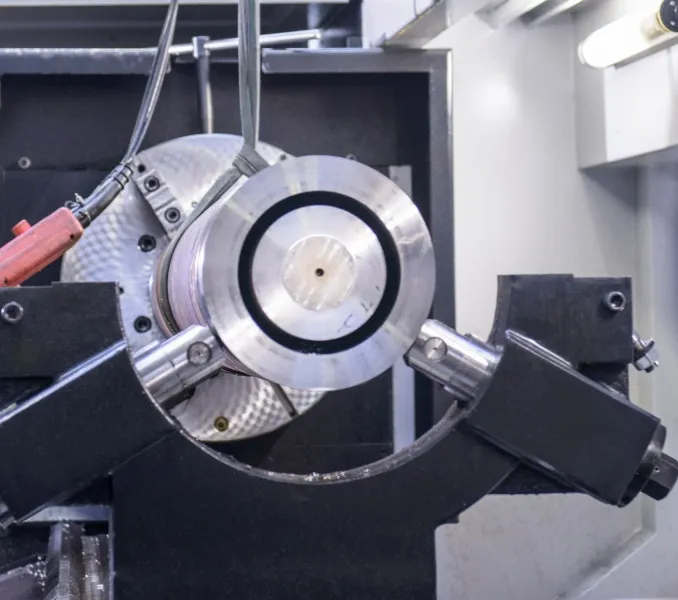

At its core, trepanning involves utilizing a trepanning tool—a cutting device designed to create annular grooves or holes. This tool is mounted on a machine that rotates it around a central axis, enabling the removal of material in a controlled manner. Trepanning is particularly suited for applications where deeper holes are necessary, and it can manage larger diameters compared to traditional drill bits.

The process generally begins with the selection of a suitable blank, typically in the form of round barstock or flat cuts of metal. The trepanning tool is then deployed to cut a circular hole while leaving behind a core, which can often be reclaimed or further processed. This approach not only conserves material but also reduces waste and machining time.

Advantages of Trepanning

-

Material Conservation: One of the key benefits of trepanning is its ability to preserve material. In contrast to full drilling operations which remove all material, trepanning leaves a solid core intact. This is particularly advantageous when working with expensive materials or alloys, such as titanium or high-performance steels.

-

High Efficiency: Trepanning is faster than traditional drilling when producing large-diameter holes. Since the tool only machines the periphery of the hole, it requires less power and reduces the cycle time significantly. This characteristic makes trepanning the preferred method for high-volume operations where time and cost savings are critical.

-

Precision and Tolerance: Modern trepanning machines can achieve tight tolerances, often within 0.001 inches (0.0254 mm). This level of precision is paramount in sectors like aerospace, automotive, and medical devices, where parts must meet stringent specifications.

-

Minimal Residual Stress: Compared to other methods, trepanning induces less heat and mechanical stress into the workpiece, preserving the integrity of the material and reducing the likelihood of distortion during machining.

Applications of Trepanning

Trepanning is versatile and widely used across several industries:

-

Aerospace: In aerospace manufacturing, trepanning is utilized to create weight-efficient components, such as bell housings and bulkheads that require precision-engineered holes.

-

Automotive: It is also employed in the automotive industry for producing parts like axles and shafts, where large-diameter holes are necessary to accommodate complex assemblies.

-

Medical Devices: The medical field benefits from trepanning in the production of implants and surgical instruments, where precision and biocompatibility are paramount.

-

Energy Sector: In the oil and gas industry, trepanning is vital for creating deep holes in drill bits or casing, allowing for efficient extraction of resources.

Comparing Trepanning to Other Machining Techniques

When evaluating trepanning against other machining methods such as gundrilling or conventional drilling, some clear differences emerge. While gundrilling is better suited for creating straight, deep holes, trepanning excels in applications where larger diameter through-holes are required without losing a core. Additionally, the forces involved in trepanning are less taxing on machinery, allowing for sustained operations without compromising on performance or speed.

Advanced Technologies in Trepanning

Recent advancements in CNC (Computer Numerical Control) technology have transformed trepanning machining capabilities. Sophisticated programming allows for complex geometries and multi-axis operations, broadening the scope of what can be produced with this technique. Furthermore, the integration of adaptive control systems enhances efficiency, automatically adjusting parameters based on real-time feedback about the machining process.

Conclusion

Trepanning machining represents a powerful solution for industries demanding efficiency, material savings, and precision. Its unique ability to create large-diameter holes while retaining the core material makes it an invaluable process in numerous applications. As technology continues to advance, the potential for trepanning machining will only expand, driving innovation in manufacturing processes across diverse sectors.