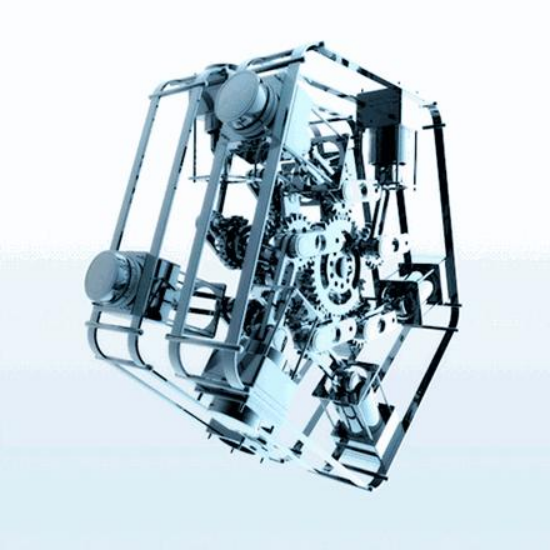

Metal non-standard parts are produced by manufacturers based on drawings provided by customers, using equipment to make corresponding products. These parts typically include molds and various industry-specific components, with tolerance requirements and surface finish specified by the customer, without a fixed standard.

Products from casting to precision machining require strict quality control, with complex and variable processes, often resulting in higher costs compared to standard parts. Non-standard parts are indispensable in modern industry. With increasing demand for high-end and customized products, the concept of non-standard parts has emerged. Their production corresponds to machining on other machine tools. The process is complex, with very strict tolerance requirements for product quality.

Not long ago, Mr. Thomas contacted DSR Machinery on Google, inquiring whether the precision of aluminum CNC machining could achieve 0.02. After analyzing the 3D drawings, the engineering department confirmed that the precision requirement could be met. After several days of production and machining, DSR Machinery delivered the finished aluminum parts. Upon testing, the precision met the customer’s requirements.

Machining Tips:

When processing non-standard parts, start by categorizing machine tool components: key components include the box body, base, spindle, flange, and sheet metal.

Production processes vary: different processes require different equipment, such as lathes (including CNC and conventional lathes), milling machines, planers, grinders, radial drills, wire cutting machines, and heat treatment furnaces.

Changing the external dimensions or functions of a workpiece is referred to as non-standard part machining. Cold and hot processing are categorized based on the temperature conditions of the workpiece. Cold processing typically occurs at room temperature without causing any chemical or phase changes to the workpiece. This includes cutting and pressure processing. Heating above or below room temperature during processing causes chemical or phase changes, known as hot processing. Heat treatment typically involves heat treatment, forging, casting, and welding.