In today’s competitive manufacturing landscape, CNC milling machines represent the backbone of precision machining, offering unmatched accuracy, speed, and versatility. From aerospace components to medical implants, the right CNC mill can dramatically impact productivity and part quality. Here, we examine some of the industry’s top-performing machines, their capabilities, and the innovations that set them apart.

1. Haas VF-4SS: The High-Speed Workhorse

1. Haas VF-4SS: The High-Speed Workhorse

A favorite among mid-sized manufacturers, the Haas VF-4SS combines affordability with high-performance machining. Its 15,000 RPM inline direct-drive spindle delivers 1,119 N·m of torque, making it ideal for aluminum, steel, and titanium. With rapid traverse rates of 50.8 m/min (2,000 IPM) and 0.001 mm positioning accuracy, this machine excels in high-mix production environments.

Key Features:

- High-speed machining (HSM) capabilities for smooth finishes in aerospace components

- Intuitive Haas control system with 3D toolpath simulation

- Chip-to-chip tool change in 1.2 seconds for reduced downtime

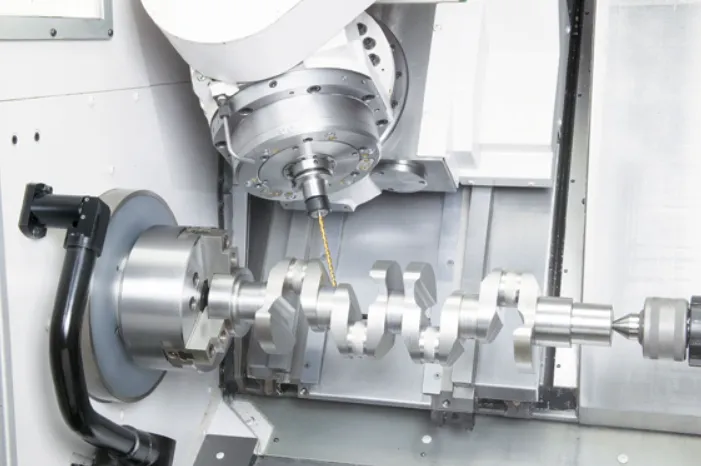

2. DMG MORI DMU 65 monoBLOCK: 5-Axis Precision for Complex Geometries

For shops requiring extreme precision in complex parts, the DMU 65 monoBLOCK stands out. This 5-axis machining center offers ±0.002 mm repeatability and a 12,000 RPM spindle with 196 N·m torque. Its rigid monoBLOCK construction minimizes vibration, ensuring superior surface finishes even in hardened steels (up to HRC 62).

Key Applications:

- Turbine blades (Inconel 718) with 0.8 µm Ra surface finish

- Medical implants (Ti-6Al-4V) with ±0.005 mm tolerance

- Automotive molds with 5-axis simultaneous contouring

3. Mazak VTC-800/30SR: Heavy-Duty Vertical Mill for Large Parts

When machining large, heavy components, the Mazak VTC-800/30SR delivers. Its 50-taper spindle provides 1,200 N·m of torque, enabling aggressive cuts in stainless steel and cast iron. The machine’s 1,500 x 800 mm table supports workpieces up to 3,000 kg, while Mazak’s SmoothX CNC ensures optimal toolpath efficiency.

Performance Highlights:

- 80 m/min rapid traverse for fast positioning

- High-pressure coolant (70 bar) for efficient chip evacuation in deep-pocket milling

- Pallet changer option for 24/7 unmanned production

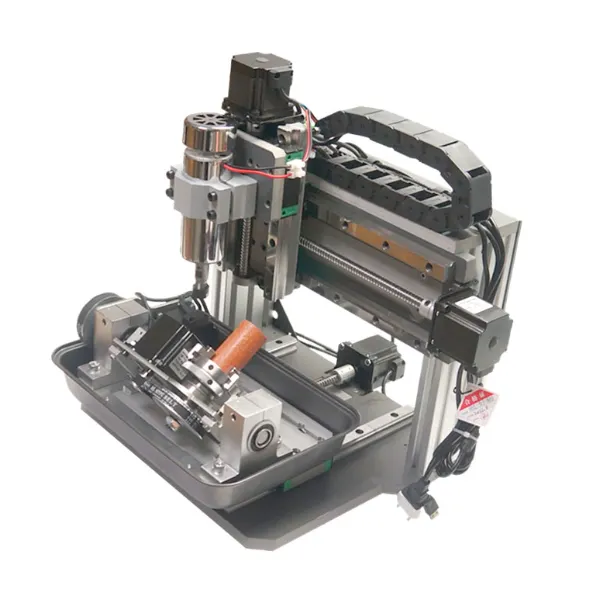

4. Okuma MB-5000H: Horizontal Machining for High-Volume Production

For manufacturers prioritizing throughput, the Okuma MB-5000H horizontal mill is a game-changer. Its 16,000 RPM spindle and 1.3-second chip-to-chip tool changes make it perfect for automotive and energy sector components. The Thermo-Friendly Concept minimizes thermal distortion, maintaining ±0.003 mm accuracy over long production runs.

Industry-Leading Innovations:

- Okuma OSP-P300 control with AI-driven thermal compensation

- Automated pallet system for lights-out machining

- Vibration-dampening cast iron structure for ultra-precise finishes

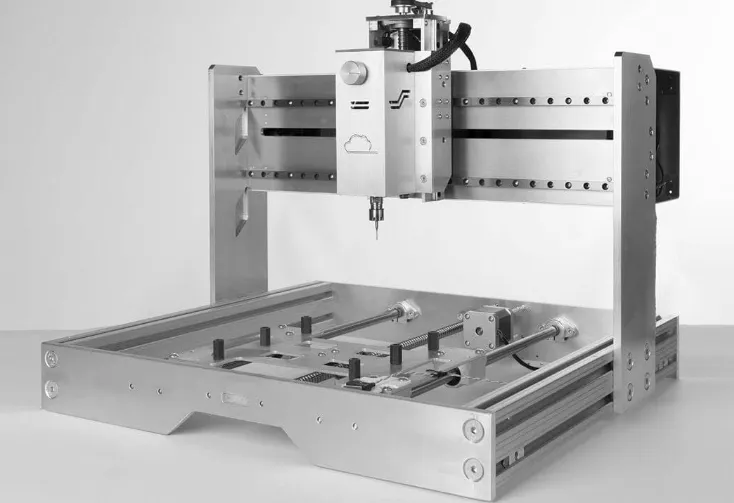

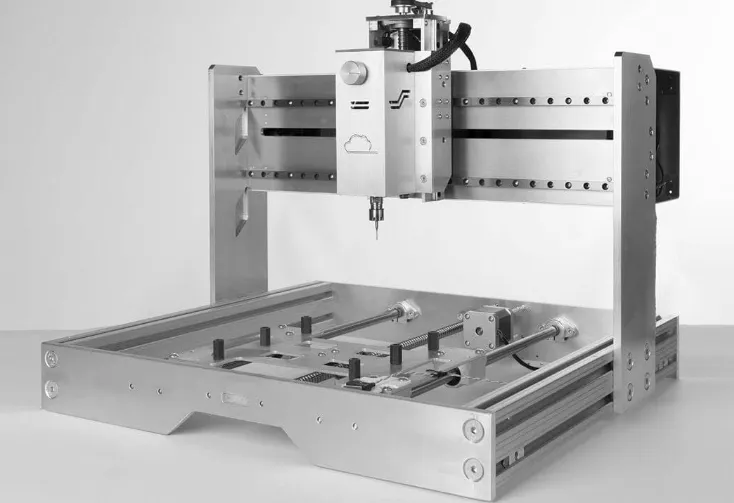

5. Brother Speedio S1000X1: Compact Speed Demon

When space and speed matter, the Brother Speedio S1000X1 shines. Despite its compact footprint, this mill boasts 16,000 RPM spindle speeds and 50 m/min rapid feeds, making it ideal for small precision parts like electronics housings and medical devices.

Why It Stands Out:

- 1.4-second tool changes (30-tool capacity)

- High-accuracy linear scales for ±0.002 mm repeatability

- Energy-efficient design consuming 40% less power than comparable mills

Emerging Trends in CNC Milling

- AI-Powered Optimization: Machines like the Makino D500 use real-time adaptive control to adjust feeds/speeds based on cutting conditions.

- Hybrid Additive/Subtractive: The Matsuura LUMEX Avance-25 combines laser metal deposition with precision milling in one setup.

- IoT & Predictive Maintenance: New FANUC CNC systems monitor spindle health, predicting failures before they occur.

Choosing the Right CNC Mill

Selecting the best machine depends on:

✔ Material requirements (aluminum vs. hardened steel)

✔ Production volume (prototyping vs. mass production)

✔ Tolerances needed (medical vs. general machining)

Final Thoughts

From Haas’s cost-effective VF series to DMG MORI’s ultra-precision 5-axis machines, today’s CNC mills offer solutions for every manufacturing need. As automation and smart machining evolve, these systems will continue pushing the boundaries of what’s possible in precision manufacturing.