The journey of a CNC prototype begins long before the first tool touches metal. It starts with a CAD model—a perfect, weightless digital representation of a part that exists only in theory. But the moment this file lands in the hands of a skilled machinist, the real challenge begins: transforming flawless digital geometry into a physical object that must obey the stubborn laws of material science, tool physics, and machine limitations. This transition from virtual to tangible is where prototyping separates the feasible from the fantasy, revealing design flaws that no simulation could predict.

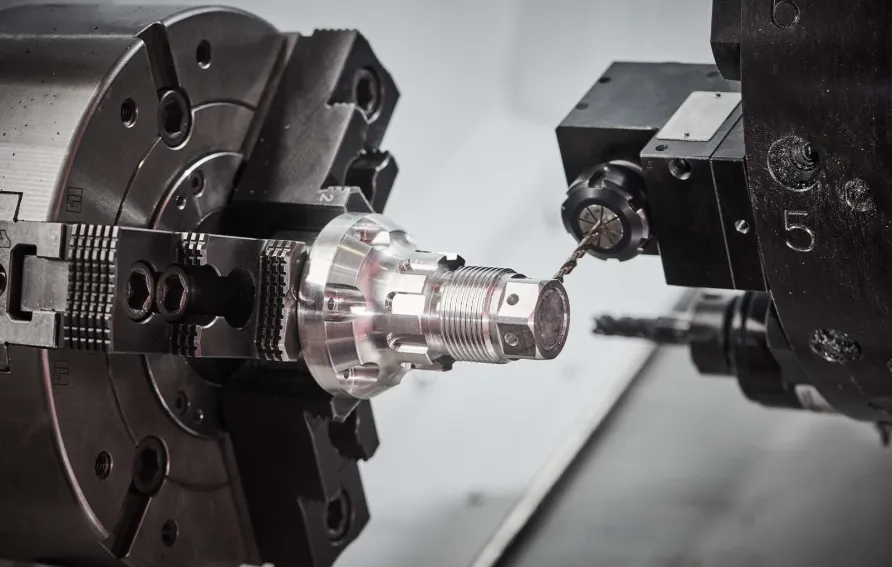

As the CNC machine roars to life, its spindle accelerating to 20,000 RPM with a rising whine, the first critical decision emerges: how to hold the raw material. Will a standard vise work, or does this oddly shaped prototype require custom fixturing? The choice here can mean the difference between a part that holds ±0.025mm tolerance and one that warps irreparably when released. Tool selection becomes equally crucial—that delicate 1mm endmill might create beautiful fine details but could snap instantly if the programmer doesn’t account for chip load in deep pockets. Meanwhile, the machine’s coolant system hisses to life, its nozzles strategically positioned to prevent thermal distortion in thin-walled sections while clearing chips from complex internal channels.

As the CNC machine roars to life, its spindle accelerating to 20,000 RPM with a rising whine, the first critical decision emerges: how to hold the raw material. Will a standard vise work, or does this oddly shaped prototype require custom fixturing? The choice here can mean the difference between a part that holds ±0.025mm tolerance and one that warps irreparably when released. Tool selection becomes equally crucial—that delicate 1mm endmill might create beautiful fine details but could snap instantly if the programmer doesn’t account for chip load in deep pockets. Meanwhile, the machine’s coolant system hisses to life, its nozzles strategically positioned to prevent thermal distortion in thin-walled sections while clearing chips from complex internal channels.

What truly distinguishes exceptional prototype machining is the machinist’s ability to “read between the lines” of a CAD file. They spot potential disasters before committing to code—recognizing that a designer’s perfect 90-degree corner would require an impossibly small tool, or that a specified surface finish would triple machining time without adding functional value. The best shops don’t just blindly follow drawings; they engage in a silent dialogue with the design, suggesting nearly invisible modifications—a 0.3mm radius here, a slightly adjusted draft angle there—that make the difference between a prototype that works and one that fails validation testing.

Material behavior becomes the wild card in this process. That aerospace-grade aluminum alloy might simulate beautifully but reveal unexpected gummy behavior during actual cutting, while a different temper could machine like butter but distort during stress testing. The prototype stage exposes these realities brutally and immediately—the way a thin flange vibrates during machining, how internal stresses manifest as warpage after cutting, or why certain hole patterns cause unpredictable tool deflection. These aren’t failures; they’re invaluable lessons that no finite element analysis could predict with equal accuracy.

Speed versus precision becomes the constant tension in prototype machining. Rush the job with aggressive parameters, and you risk scrapping the only piece of expensive material. Go too cautiously, and the 72-hour delivery window slips away. The magic happens when machinists leverage their experience to find the sweet spot—knowing exactly how fast they can push a 3/8″ endmill through titanium before harmonics become problematic, or when to switch from a roughing tool to a finishing tool despite the toolchange time penalty. This balancing act extends to post-processing too—that beautiful as-machined surface might look perfect until the anodizing tank reveals subtle tool marks invisible to the naked eye.

The most valuable prototypes aren’t necessarily the ones that function perfectly, but those that fail in instructive ways. A cracked boss shows where stress concentrations need redesign; a stuck assembly reveals tolerance stack issues; a vibrating component exposes unanticipated resonance frequencies. Each “failure” becomes a data point more valuable than any simulation output—a physical manifestation of real-world physics that no software can fully replicate. This is why CNC prototyping remains irreplaceable despite advances in 3D printing and virtual testing—because metal cut by metal tells truths that pixels cannot.

In the hands of master machinists, CNC prototyping transcends simple part production. It becomes a form of mechanical divination—interpreting the whispers of stressed materials, decoding the stories told by chip formation patterns, and translating digital perfection into physical excellence. Every prototype that emerges from the machine, whether successful or flawed, carries with it the accumulated wisdom of a thousand previous cuts—each one teaching us something new about how to bridge the gap between what we can imagine and what we can actually build.