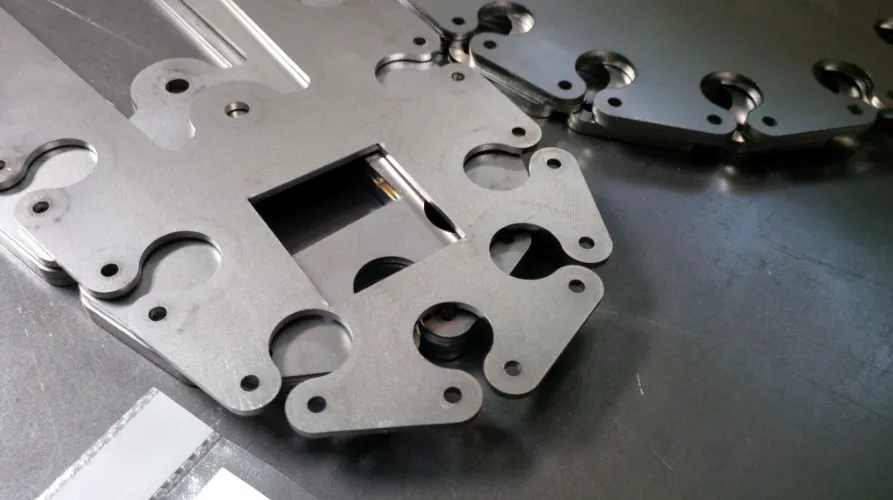

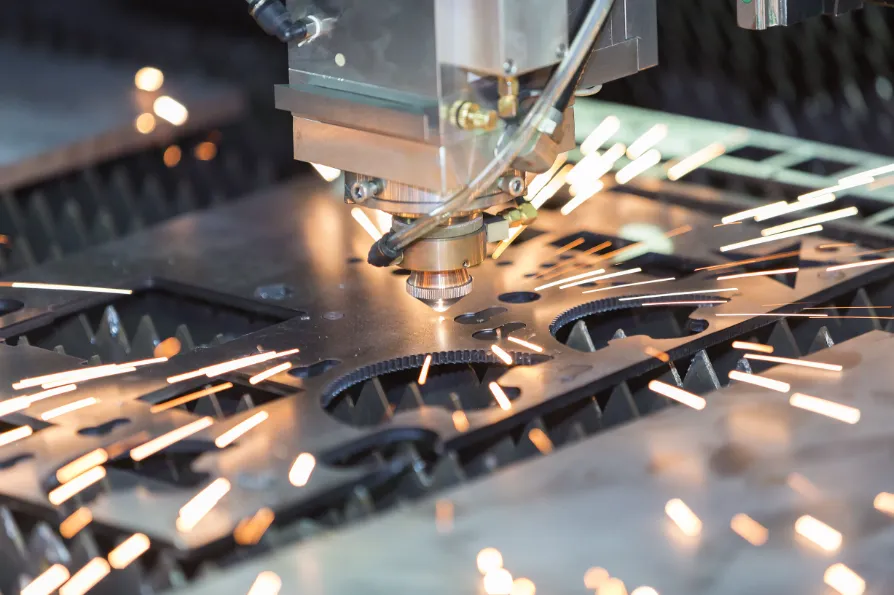

The evolution of steel laser cutting has revolutionized metal manufacturing, offering unparalleled precision, speed, and versatility across industries. Modern fiber laser systems can process carbon steel up to 30 mm thick with cutting tolerances of ±0.1 mm, while maintaining kerf widths as narrow as 0.2 mm. This technology has become indispensable for applications ranging from automotive chassis components to architectural metalwork, where dimensional accuracy and edge quality are critical.

Laser Cutting Technologies for Steel

Fiber lasers now dominate the steel cutting market, with wavelengths of 1,070 nm providing optimal absorption in ferrous materials. A 6 kW fiber laser can cut 10 mm mild steel at speeds exceeding 8 m/min, while 12 kW systems handle 20 mm plate at 3.5 m/min – approximately three times faster than equivalent CO₂ lasers. The latest 30 kW lasers push these boundaries further, cleanly processing 30 mm structural steel at 1.2 m/min with nitrogen assist gas.

For stainless steel applications, manufacturers increasingly adopt bright cutting techniques using high-purity nitrogen (99.999%) at pressures up to 25 bar. This process produces oxide-free edges with surface roughness below 3.2 μm Ra on 6 mm 304 stainless, eliminating the need for secondary finishing in visible applications like elevator panels or kitchen equipment.

Material Considerations and Cutting Parameters

The laser cutting performance varies significantly with steel grade and composition:

- Mild Steel (S235JR):

- 4 kW laser: 12 m/min @ 2 mm, 4 m/min @ 6 mm

- Oxygen-assisted cutting achieves clean edges with dross-free results up to 20 mm thickness

- High-Strength Steel (S690QL):

- Requires 20% lower feed rates than mild steel

- Preheating to 80°C prevents microcracking in thicknesses above 15 mm

- Stainless Steel (316L):

- Nitrogen cutting at 15 bar produces burr-free edges

- 8 kW laser achieves 6 m/min @ 3 mm with 0.3° perpendicularity tolerance

Industrial Applications and Economic Impact

Automotive manufacturers leverage laser cutting for body-in-white components, where a single 10 kW laser can blank 1.2 mm galvannealed steel at 25 m/min, producing 600+ parts per hour with positional repeatability of ±0.05 mm. The construction sector benefits from the technology’s ability to process 20 mm structural steel beams with complex copes and connections at 1.5 m/min – a task that would require five times longer with plasma cutting.

In heavy industry, laser systems now integrate with robotic arms for 3D cutting of pressure vessel components. Systems like the Trumpf TruLaser Cell 7040 maintain ±0.2 mm accuracy when bevel-cutting 25 mm carbon steel pipe at 45° angles, a capability critical for nuclear and petrochemical applications.

Quality Control and Process Monitoring

Advanced monitoring systems have significantly improved cutting consistency:

- Capacitive height sensors maintain nozzle standoff distance within ±0.03 mm

- Coaxial cameras detect cut front anomalies in real-time, adjusting parameters to prevent defects

- Spectrometers analyze plasma emissions to identify material grade variations automatically

These technologies reduce scrap rates by up to 40% in high-volume production, as demonstrated by a recent case study at a truck frame manufacturer processing 8 mm high-strength steel.

Emerging Innovations

The frontier of steel laser cutting includes several promising developments:

- Blue Laser Cutting (450 nm wavelength)

- Improved absorption in copper-alloyed steels

- Enables cleaner cuts on 3 mm weathering steel at 10 m/min

- Hybrid Laser-Arc Cutting

- Combines laser precision with arc cutting thickness capacity

- Processes 50 mm shipbuilding steel with 30% less bevel angle variation than plasma

- AI-Powered Parameter Optimization

- Machine learning algorithms predict optimal gas pressures and focal positions

- Reduces setup time by 70% when switching between steel grades

Environmental and Safety Considerations

Modern laser cutting systems address sustainability concerns through:

- Fume extraction efficiency exceeding 99% with HEPA filtration

- Energy consumption reduced to 8 kWh per hour for 4 kW systems

- Scrap minimization through AI nesting software achieving 92% material utilization

As laser sources continue advancing in power and efficiency, steel cutting capabilities will expand further – with 40 kW systems now entering the market promising single-pass cutting of 40 mm marine-grade steel at production-relevant speeds. This relentless technological progress ensures laser cutting remains the gold standard for precision steel fabrication across industries.