BlOG

Get a Free Quote

Acetal vs. Delrin: Key Differences and Applications

Acetal and Delrin are both engineering plastics known for their impressive mechanical properties; however, they differ significantly in performance and applications. Acetal, also known as polyoxymethylene (POM), is a thermoplastic that offers high strength, stiffness, and excellent dimensional stability.

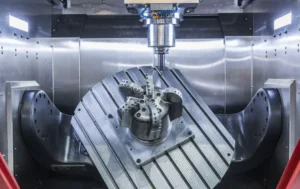

CNC Programming’s Role in Modern Manufacturing

CNC programming, short for Computer Numerical Control programming, is an essential aspect of modern manufacturing that revolutionizes how products are machined and assembled. At its core, CNC programming involves writing codes that direct machines, such as mills, lathes, and routers, to perform specific tasks with precision and accuracy.

Precision CNC Acrylic Services: Mastering the Art of Optical-Grade Fabrication

CNC machining of acrylic (PMMA) represents one of the most demanding disciplines in plastic fabrication, requiring an entirely different approach than metal machining to achieve crystal-clear results.

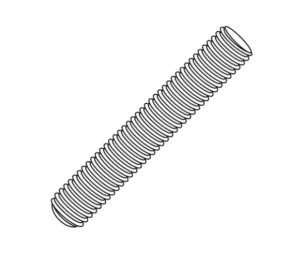

Understanding Left-Hand Threads: A Comprehensive Guide

Left-hand threads, often referred to as left-hand screws or reverse threads, play a crucial role in various mechanical applications. Unlike standard right-hand threads, which tighten when turned clockwise, left-hand threads require a counterclockwise rotation to tighten.

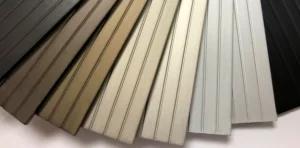

How to Anodize Aluminum: A Technical Deep Dive into Oxide Growth Engineering

Anodizing aluminum transforms the metal’s surface through controlled electrochemical oxidation, creating a porous aluminum oxide layer that outperforms the base material in hardness, corrosion resistance, and adhesive properties.

The Art and Science of Bending Aluminum

Bending aluminum is a delicate balance between metallurgical precision and mechanical intuition, where the material’s crystalline structure dictates every decision from tool selection to bend radius.

Advancements and Innovations in Boring Machining Techniques

Boring machining is a precision technique primarily used to enlarge existing holes in a workpiece to achieve greater diameters and improved dimensional accuracy. As industries evolve, so do the technologies and methods employed in boring operations.

Micro Machining: An Overview of Technologies, Applications, and Trends

Micro machining is a specialized field of manufacturing that focuses on the production of incredibly small parts and features, typically measured in micrometers (one-millionth of a meter).

The Art and Science of CNC Prototyping: Where Digital Dreams Meet Physical Reality

The journey of a CNC prototype begins long before the first tool touches metal. It starts with a CAD model—a perfect, weightless digital representation of a part that exists only in theory. But the moment this file lands in the hands of a skilled machinist, the real challenge begins: transforming flawless digital geometry into a physical object that must obey the stubborn laws of material science, tool physics, and machine limitations.

CNC Machine Types: The Unsung Heroes of the Shop Floor

Every machinist knows the truth – not all CNC machines are created equal. Each type has its own quirks, strengths, and that one particular job it was born to do. Let’s cut through the brochure specs and talk about what these machines really do when the shop doors close.

What is Automation?

Automation isn’t just about machines replacing human labor—it’s a fundamental shift in how we approach tasks, blending mechanics, computing, and decision-making to streamline processes that once demanded constant human oversight. At its core, automation involves programming systems to execute repetitive or complex actions with minimal intervention, whether in a factory assembling cars or a smart thermostat adjusting your home’s temperature.

3D Machining-The Digital Transformation of Material Processing

Modern manufacturing has entered an era where complex geometries emerge from raw material blocks with unprecedented precision, thanks to advanced 3D machining techniques. Unlike traditional 2.5D machining limited to planar operations, true 3D machining enables simultaneous multi-axis tool movement that follows complex surface contours with sub-millimeter accuracy.