BlOG

Get a Free Quote

Wire Cutting Machines: Revolutionizing Manufacturing Processes

In recent years, the demand for precision and efficiency in manufacturing has led to the rapid evolution of various tools and technologies. One such advancement is the wire cutting machine, a device that has become essential in sectors such as aerospace, automotive, electronics, and metal fabrication.

CNC Wood Lathes: Revolutionizing Woodworking Through Digital Craftsmanship

The woodworking industry has undergone a quiet revolution with the widespread adoption of CNC wood lathes, machines that blend centuries-old turning techniques with cutting-edge digital control. These sophisticated systems now dominate high-end production shops, with industry reports indicating a 47% increase in CNC lathe installations for wood applications since 2018.

CNC Precision Machining: The Backbone of Modern Manufacturing

CNC precision machining has revolutionized manufacturing by delivering accuracy, repeatability, and efficiency at unprecedented levels. Modern CNC machines routinely achieve tolerances within ±0.005 mm (5 microns), with high-end systems pushing this to ±0.001 mm (1 micron) for critical aerospace and medical components.

Perforated Metal Sheet: Precision Engineered for Performance and Aesthetics

Perforated metal sheets have become indispensable across industries, offering an optimal balance of strength, airflow, and design flexibility. Modern manufacturing techniques can produce holes as small as 0.3mm diameter with ±0.02mm positional accuracy in stainless steel sheets up to 6mm thick.

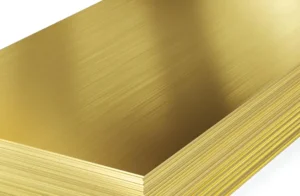

Brass Sheet Metal: A Versatile Material in Modern Industries

Brass sheet metal, an alloy primarily composed of copper and zinc, has been a cornerstone in various industries for centuries. Renowned for its excellent machinability, corrosion resistance, and aesthetic appeal, brass sheet metal continues to play a pivotal role in applications ranging from decorative arts to industrial machinery.

Industrial Machining: The Engine of Modern Manufacturing

Industrial machining has evolved into a highly sophisticated discipline, combining advanced materials science with digital precision to meet the demands of global manufacturing. Modern CNC machining centers now routinely achieve tolerances of ±0.005 mm (5 microns) on production runs exceeding 10,000 parts, with high-speed spindles reaching 40,000 RPM for aluminum aerospace components.

Turret Lathes: The Workhorse of Precision Turning Operations

Turret lathes remain indispensable in modern manufacturing, offering unmatched efficiency for medium-to-high volume production of precision turned parts. Unlike conventional engine lathes, these machines feature a hexagonal turret capable of holding 6-12 tools simultaneously, reducing changeover time by up to 80% compared to manual tooling systems.

Industrial Automation Services: Revolutionizing Modern Manufacturing

Industrial automation services have become a pivotal force in transforming the landscape of modern manufacturing. By leveraging advanced technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT), these services enhance efficiency, improve product quality, and reduce operational costs.

Molded Metal: Precision Manufacturing Through Advanced Forming Processes

Molded metal components represent a critical segment of modern manufacturing, with die casting alone accounting for over 50% of all non-ferrous metal parts production globally.

Lathe vs. Mill: Understanding the Key Differences in Machining

In the world of manufacturing, machining plays a crucial role in producing precise components and parts. Two of the most commonly used machine tools in this process are the lathe and the milling machine.

What is a Milling Machine?

A milling machine is an essential tool in the fields of manufacturing and metalworking, used for removing material from a workpiece through the use of rotary cutters. It is vital for precision machining, allowing for the shaping and finishing of various materials.

Precision Aerospace CNC Machining: Meeting the Demands of Flight

The aerospace industry represents the pinnacle of CNC machining, where tolerances measured in microns and material performance under extreme conditions dictate machining strategies.