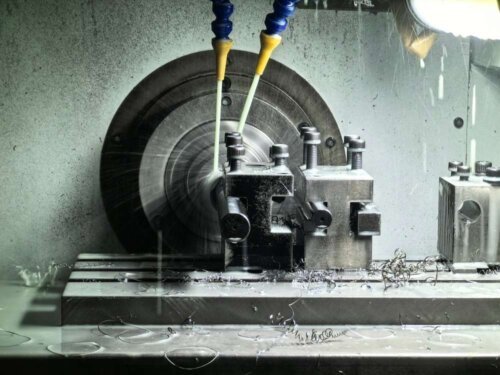

In the fast-paced world of product development, Rapid Prototype Machining has emerged as a game-changer, enabling engineers and designers to quickly transform ideas into tangible prototypes. From automotive components to medical devices, rapid prototyping bridges the gap between concept and reality, reducing time-to-market and ensuring design accuracy. But what exactly is rapid prototype machining, how does it work, and why is it so crucial? Let’s dive into the mechanics, applications, and future of this transformative technology.

What is Rapid Prototype Machining?

Rapid Prototype Machining refers to the use of CNC machining to quickly produce functional prototypes from digital designs. Unlike traditional prototyping methods, which can take weeks or months, rapid prototyping delivers parts in days, allowing for faster design iterations and validation. This process is particularly valuable in industries where precision, speed, and material versatility are critical.

Key Characteristics of Rapid Prototype Machining

- Speed: Parts can be produced in as little as 24–48 hours.

- Precision: Tolerances as tight as ±0.005 inches (0.127 mm).

- Material Versatility: Works with metals, plastics, and composites.

- Functionality: Prototypes are often functional, not just visual models.

How Does Rapid Prototype Machining Work?

How Does Rapid Prototype Machining Work?

Rapid prototype machining combines advanced CNC technology with efficient workflows to deliver high-quality prototypes quickly. Here’s a breakdown of the process:

1. Design and CAD Modeling

The process begins with a 3D CAD model created using software like SolidWorks, Fusion 360, or AutoCAD. This digital blueprint is the foundation for the machining process.

- Pro Tip: Use Design for Manufacturability (DFM) principles to optimize your CAD model for machining, reducing production time and costs.

2. Material Selection

The choice of material depends on the prototype’s intended use. Common options include:

- Metals: Aluminum (lightweight, machinable), stainless steel (durable, corrosion-resistant).

- Plastics: ABS (affordable, versatile), polycarbonate (impact-resistant), nylon (wear-resistant).

- Composites: Carbon fiber (lightweight, strong), fiberglass (durable, corrosion-resistant).

3. CNC Machining

The CNC machining process involves removing material from a workpiece using cutting tools. Here’s a step-by-step overview:

- Tool Selection: Choose the right tool for the job, such as end mills, drills, or lathe tools.

- Cutting Parameters: Set spindle speed (RPM), feed rate (IPM), and depth of cut (DOC) based on material and tool type.

- Machining Operation: Execute the G-code program to perform the cutting operation.

Cutting Parameter Calculations

To optimize machining, use the following formulas:

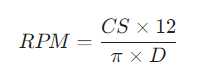

- Spindle Speed (RPM):

Where:

- CS= Cutting speed (SFM, surface feet per minute).

- D= Tool diameter (inches).

Scenario: For machining aluminum with a cutting speed of 500 SFM and a 0.5-inch end mill:

Warning: Exceeding recommended RPM can cause tool wear or breakage. Always consult tool manufacturer guidelines.

- Feed Rate (IPM):

IPM=RPM×FPT×N

Where:

- FPT = Feed per tooth (inches).

- N = Number of teeth on the tool.

Scenario: For a 4-flute end mill at 3820 RPM and 0.002 inches per tooth:

IPM=3820×0.002×4=30.56IPM,

- Material Removal Rate (MRR):

MRR=DOC×WOC×IPM

Where:

- DOC = Depth of cut (inches).

- WOC = Width of cut (inches).

Scenario: For a 0.1-inch DOC and 0.5-inch WOC at 30.56 IPM:

![]()

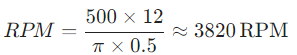

Real-World G-Code Example

Here’s an example of a facing operation using G-code, including tool compensation and coolant commands:

Key G-Code Explanations:

- G43 H01: Activates tool length compensation using offset H01.

- M08/M09: Turns coolant on/off to prevent overheating and improve tool life.

- G00/G01: Rapid and linear motion commands, respectively.

4. Finishing and Inspection

After machining, prototypes may undergo finishing processes like sanding, polishing, or coating. Inspection tools like CMMs (Coordinate Measuring Machines) ensure dimensional accuracy.

Why is Rapid Prototype Machining Essential?

1. Accelerated Time-to-Market

Rapid prototyping reduces the time required to produce functional prototypes, enabling faster design iterations and validation. According to a 2022 report by Engineering.com, companies using rapid prototyping saw a 40% reduction in product development time.

2. Cost-Effective Design Validation

By identifying design flaws early, rapid prototyping minimizes costly revisions during mass production. A 2021 study by Manufacturing Global found that rapid prototyping reduced development costs by up to 30%.

3. Material and Functional Testing

Rapid prototypes are often made from the same materials as final products, allowing for accurate functional and stress testing.

Technical Comparison: Rapid Prototyping Methods

| Aspect | CNC Machining | 3D Printing | Injection Molding |

|---|---|---|---|

| Speed | Fast (24–48 hours) | Very Fast (hours) | Slow (weeks for tooling) |

| Precision | High (±0.005 inches) | Moderate (±0.01 inches) | High (±0.002 inches) |

| Material Options | Wide range (metals, plastics, composites) | Limited (plastics, resins) | Limited (plastics, some metals) |

| Cost | Moderate | Low | High (tooling costs) |

| Functionality | Fully functional | Limited functionality | Fully functional |

Challenges and Limitations

1. High Initial Investment

CNC machines and tooling can be expensive, with costs ranging from $50,000 to over $500,000. Here’s a breakdown of typical costs:

- CNC Machine: $50,000–$500,000.

- Tooling: $5,000–$20,000 annually.

- Maintenance: $10,000–$30,000 annually.

2. Skilled Labor Shortage

Operating CNC machines requires specialized training. A 2021 report by IndustryWeek highlighted a growing skills gap, with many companies struggling to find qualified machinists.

3. Material Waste

Machining is a subtractive process, meaning it generates material waste. For complex designs, this can result in significant scrap.

The Future of Rapid Prototype Machining

1. Smart Manufacturing

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) is revolutionizing rapid prototyping. For example, predictive maintenance systems use AI to monitor tool wear and optimize machining parameters in real-time.

2. Hybrid Prototyping

Combining additive manufacturing (3D printing) with CNC machining allows for the creation of complex geometries with minimal waste. Hybrid machines are becoming increasingly popular in industries like aerospace and medical devices.

3. Advanced Materials

New materials, such as high-performance polymers and metal composites, are expanding the possibilities for rapid prototyping.

Conclusion

Rapid prototype machining is a cornerstone of modern product development, enabling faster, more accurate, and cost-effective prototyping. From automotive components to medical devices, this technology is driving innovation across industries. While challenges like high costs and skilled labor shortages persist, advancements in technology are paving the way for a smarter, more efficient future.

If you’re considering rapid prototype machining, prioritize understanding your specific needs and explore options like hybrid machines or outsourcing. With the right tools and expertise, the possibilities are endless.

References

- Engineering.com (2022) – Report on rapid prototyping in product development.

- Manufacturing Global (2021) – Study on cost savings with rapid prototyping.

- IndustryWeek (2021) – Article on the skills gap in CNC machining.

- Aerospace Manufacturing and Design (2022) – Report on rapid prototyping in aerospace.

- Medical Design & Outsourcing (2023) – Case study on rapid prototyping in medical devices.