Precision stamping is a high-volume manufacturing process that produces metal components with tight tolerances and complex geometries. This cold-forming technique utilizes specialized presses and tooling to transform sheet metal into functional parts for various industries.

Stamping Methods and Equipment

Stamping Methods and Equipment

Manufacturers employ multiple stamping techniques depending on part requirements:

- Fine Blanking

- Combines extrusion and stamping in a single stroke

- Achieves smooth shear surfaces (Ra 0.4-1.6μm)

- Maintains tolerances within ±0.0005″ per inch

- Requires triple-action presses (100-3,000 ton capacity)

- Progressive Die Stamping

- Performs multiple operations simultaneously in a strip-fed process

- Typical production rates: 100-1,500 strokes per minute

- Handles material thicknesses from 0.002″ to 0.250″

- Incorporates 5-30 stations in a single die set

- Transfer Die Stamping

- Uses mechanical fingers to move parts between stations

- Suitable for larger components (up to 24″ length)

- Maintains ±0.002″ positional accuracy

- Multi-Slide Stamping

- Features 4-6 tool slides operating perpendicular to main ram

- Forms complex 3D shapes in a single hit

- Common for small electrical contacts and springs

Material Specifications

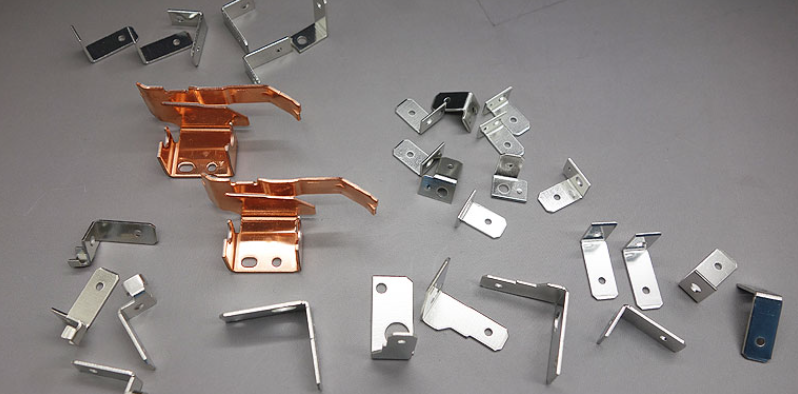

Precision stamping processes various metals:

- Steel Alloys

- Low-carbon steels (1008, 1010)

- High-strength steels (HSLA 340, 420)

- Stainless steels (301, 304, 17-7PH)

- Non-Ferrous Metals

- Aluminum (1100, 5052)

- Copper alloys (C110, C260)

- Nickel silver (C7521)

- Exotic Materials

- Beryllium copper (C17200)

- Kovar (ASTM F15)

- Shape memory alloys (Nitinol)

Material thickness typically ranges from 0.001″ foil to 0.125″ plate, with specific alloys selected for conductivity, corrosion resistance, or magnetic properties.

Tooling Technology

Precision stamping dies incorporate advanced features:

- Guiding Systems

- Precision ball bearings (0.0002″ clearance)

- Four-pillar constructions for alignment

- Cutting Components

- Powder metallurgy tool steels (M2, M4)

- Polycrystalline diamond (PCD) inserts

- CVD-coated punches (TiCN, AlCrN)

- Forming Elements

- Multi-stage forming stations

- Nitrogen-loaded pressure pads

- Sensor-equipped die protection

Tool life ranges from 500,000 cycles for complex forms to 10M+ for simple blanks, with maintenance intervals based on monitored wear patterns.

Dimensional Capabilities

Modern precision stamping achieves:

- Tolerances

- ±0.0005″ for critical dimensions

- ±0.001″ typical for most features

- Angular tolerances within ±0.5°

- Geometric Complexity

- Formed threads (M1.6-M12)

- Micro holes (0.008″ diameter)

- Raised logos (0.003″ relief)

- Edge breaks (0.002″ radius)

- Surface Characteristics

- Burr-free edges (<0.0003″)

- Controlled surface textures

- Preserved grain structure

Quality Control Systems

Manufacturing facilities implement comprehensive inspection protocols:

- In-Process Monitoring

- Vision systems (5MP cameras)

- Laser micrometers (0.00004″ resolution)

- Force monitoring (2% load accuracy)

- Final Inspection

- Optical comparators (50x magnification)

- CMM measurement (±0.0001″ repeatability)

- Surface roughness testers (0-500μm range)

- Material Verification

- XRF analyzers for alloy composition

- Microhardness testing (HV scale)

- Grain structure analysis

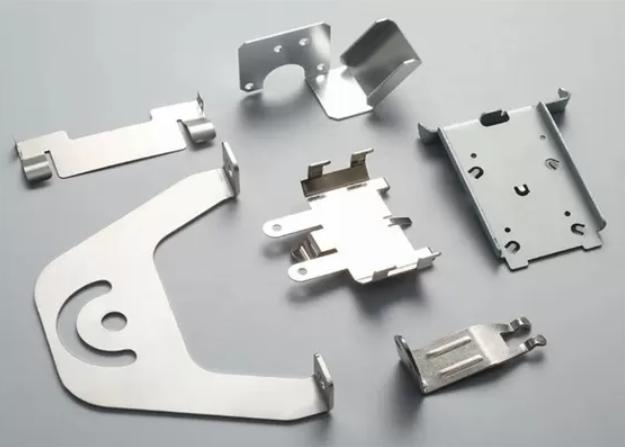

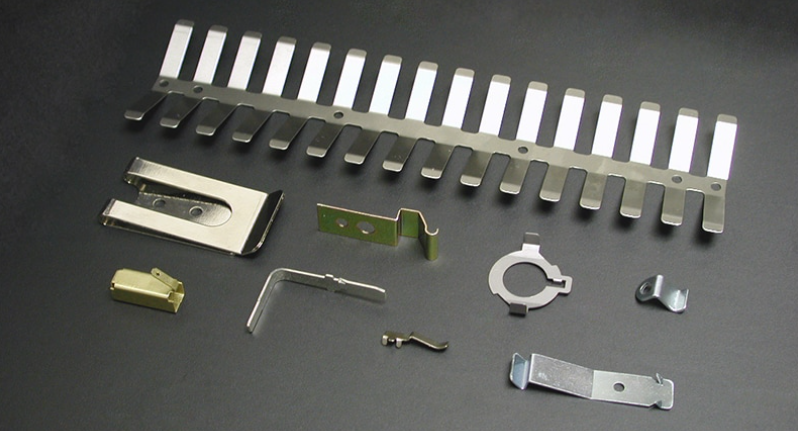

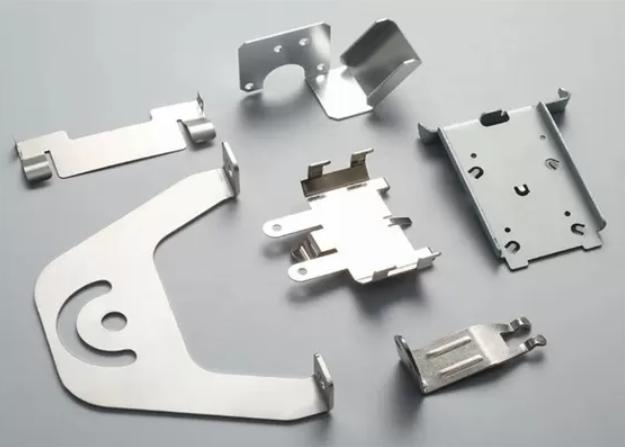

Industry Applications

Precision stamped components serve critical functions across sectors:

Electronics

- Connector pins (0.010″ pitch)

- Shielding cans (0.004″ wall)

- Battery contacts (0.002″ flatness)

Medical Devices

- Surgical tool components

- Implantable marker bands

- Dispenser mechanisms

Automotive

- Fuel injector shims

- Sensor housings

- Transmission plates

Aerospace

- Avionics brackets

- Turbine seals

- Antenna components

Production Economics

Precision stamping offers distinct advantages:

- High Volume Output

- 1M+ parts per month capability

- 24/7 production with <1% downtime

- Material Utilization

- 85-98% yield through nesting optimization

- Scrap recycling programs

- Cost Efficiency

- $0.001-$5.00 per part depending on complexity

- 30-70% cost reduction vs. machining

Emerging Technologies

The field continues advancing through:

- Smart Tooling with embedded sensors

- AI-Powered Process Control

- Hybrid Additive/Stamping Methods

- Nano-Structured Tool Coatings

Precision stamping remains a foundational manufacturing process, combining speed, accuracy, and repeatability to produce mission-critical components for modern technology applications.