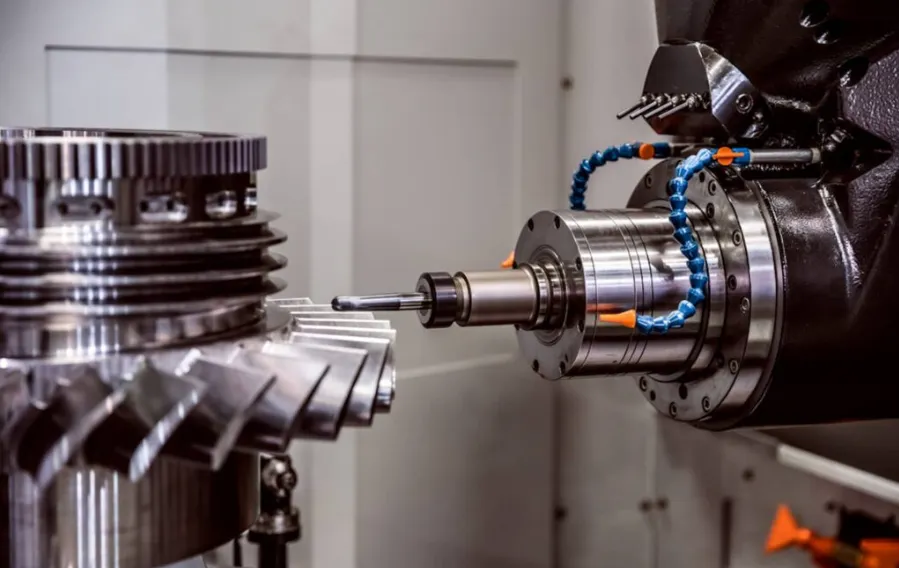

The aerospace industry represents the pinnacle of CNC machining, where tolerances measured in microns and material performance under extreme conditions dictate machining strategies. Modern aerospace CNC machines routinely hold positional accuracies of ±0.0002″ (5 microns) over meter-long workpieces, with thermally compensated ballscrews and linear scales maintaining this precision across 40°C temperature variations common in aircraft component service. Five-axis machining centers like the DMG MORI HSC 75 linear process titanium alloys at 18,000 RPM with 0.004″ chip loads, achieving metal removal rates of 15 in³/min while preserving tool life in these notoriously difficult-to-machine materials.

Material science drives aerospace machining innovation. The transition from conventional aluminum 7075-T6 to lithium-aluminum alloys (2099, 2195) has required entirely new tooling approaches – diamond-coated carbide end mills now last 8-10 times longer than uncoated tools when machining these silicon-rich alloys at 1,200-1,500 SFM. For nickel superalloys like Inconel 718, high-pressure coolant delivery at 1,000 psi through the spindle enables effective chip evacuation during slotting operations, preventing work hardening that could reduce fatigue life by 30%. The latest cryogenic machining systems using liquid nitrogen at -320°F (-196°C) demonstrate even greater promise, reducing cutting forces by 40% when machining Ti-6Al-4V while simultaneously improving surface integrity.

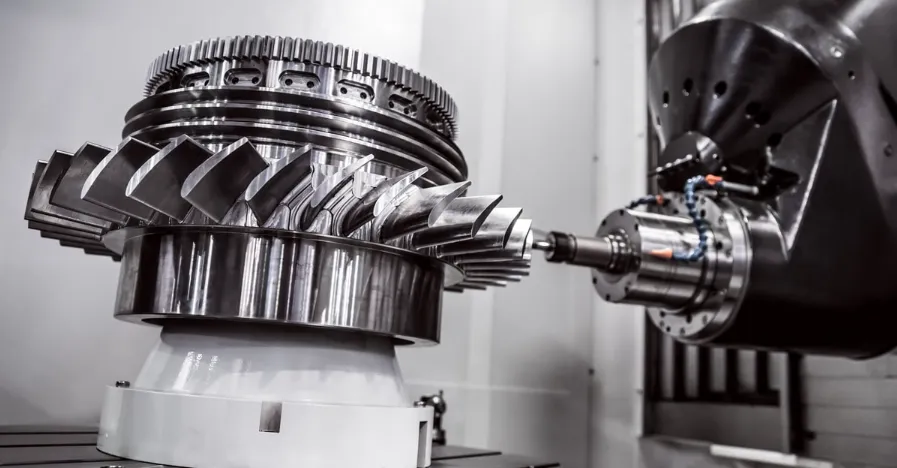

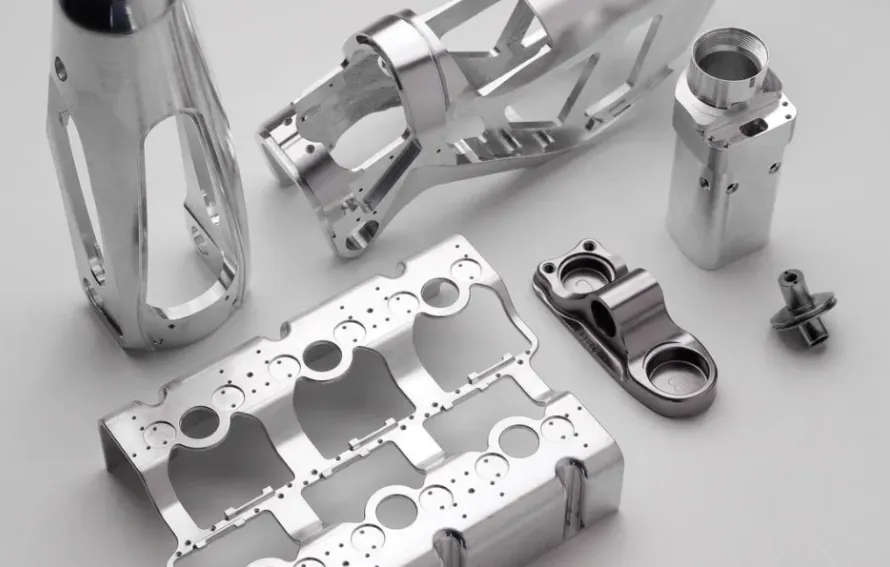

Aerospace structural components demand unique machining solutions. Wing spar pockets machined from aluminum 7050-T7451 plates require dynamic toolpath strategies that maintain constant cutter engagement, with modern CAM software adjusting feed rates every 0.0005″ to prevent harmonic vibration in thin webs. Turbine disk slotting presents the opposite challenge – roughing Inconel 718 forgings requires trochoidal milling paths with 0.030″ radial stepovers at 250 SFM to distribute tool wear evenly across the flute length. The most advanced aerospace shops now employ hybrid additive-subtractive cells where near-net-shape laser metal deposition is followed by precision CNC machining in a single setup, reducing material waste by 70% for complex combustion chamber components.

Aviation safety regulations impose rigorous documentation requirements on aerospace machining. Each critical aircraft component requires full traceability of machining parameters – spindle load graphs, coolant pressure logs, and tool wear measurements are archived for 30+ years in some cases. This data collection enables process control unseen in other industries; for example, Boeing’s South Carolina facility uses real-time vibration analysis to detect tool wear progression during 20-hour-long CFRP/aluminum stack drilling operations, automatically compensating for diameter reduction before holes exceed ±0.0005″ tolerances.

Emerging technologies continue pushing aerospace machining capabilities. Ultrasonic-assisted milling systems operating at 20kHz now enable efficient machining of carbon fiber reinforced polymers (CFRP), reducing delamination defects by 90% compared to conventional methods. For optical-quality surfaces on aluminum mirror mounts, diamond turning lathes with air-bearing spindles achieve 2nm Ra finishes through sub-micron tool positioning control. Perhaps most impressively, micro-machining centers producing fuel injector nozzles maintain 0.00004″ (1 micron) feature accuracy while operating in climate-controlled clean rooms where temperature fluctuates less than ±0.1°C/hour.

The future of aerospace CNC machining lies in cognitive manufacturing systems. Airbus’s “Factory of the Future” initiative has demonstrated self-optimizing machining cells where artificial intelligence analyzes 200+ sensor inputs to predict optimal parameters for unfamiliar alloys. Meanwhile, digital twin technology allows simulation of entire machining processes before metal is cut – Lockheed Martin reports this approach has reduced F-35 component qualification time by 40%. As spacecraft components demand ever-higher precision (James Webb Space Telescope beryllium mirrors required 10nm surface accuracy), aerospace CNC machining continues to redefine the boundaries of what’s mechanically possible.