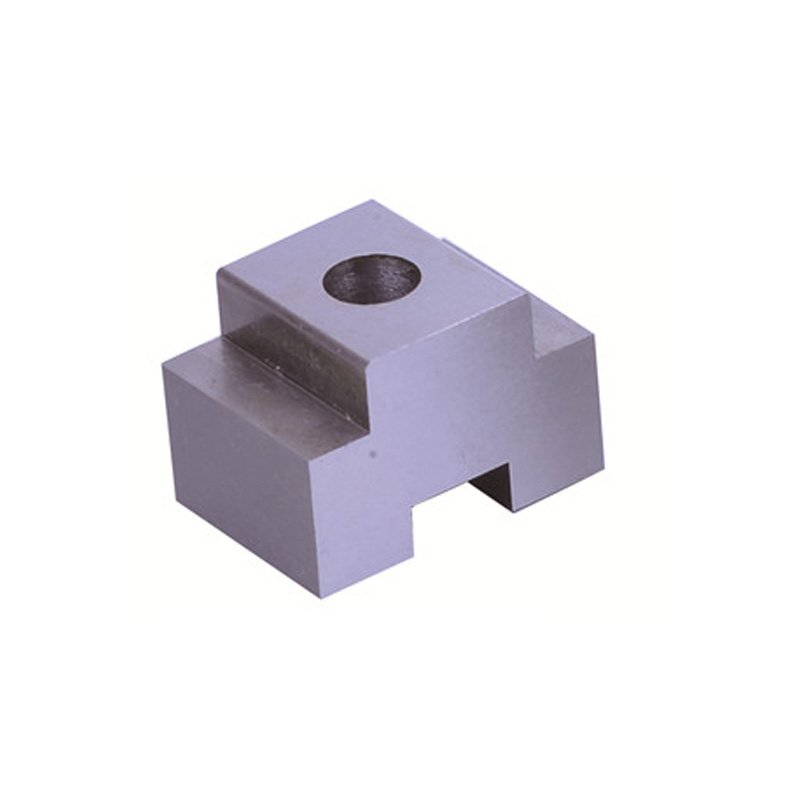

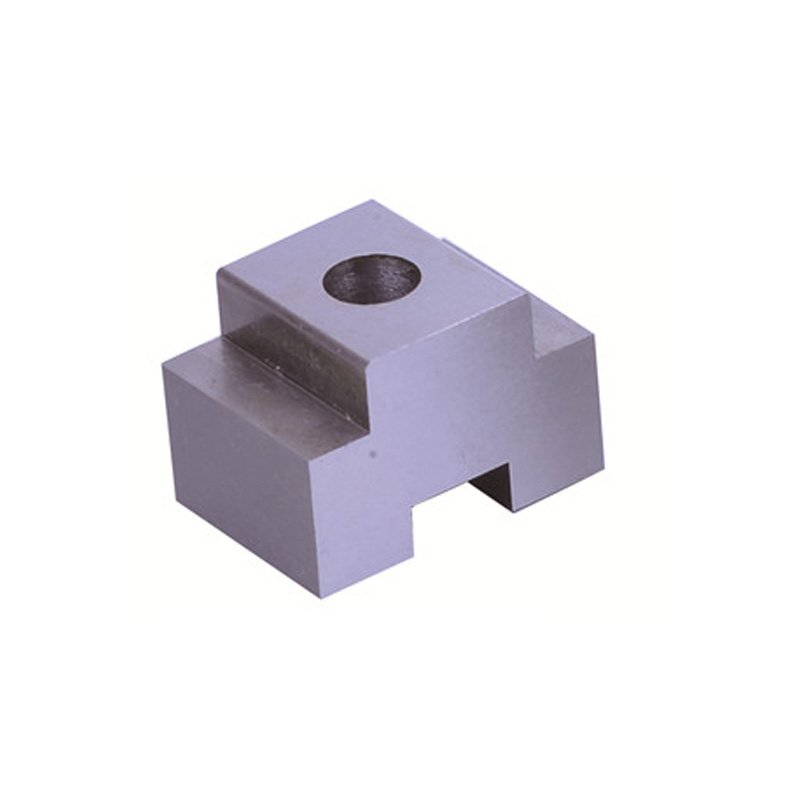

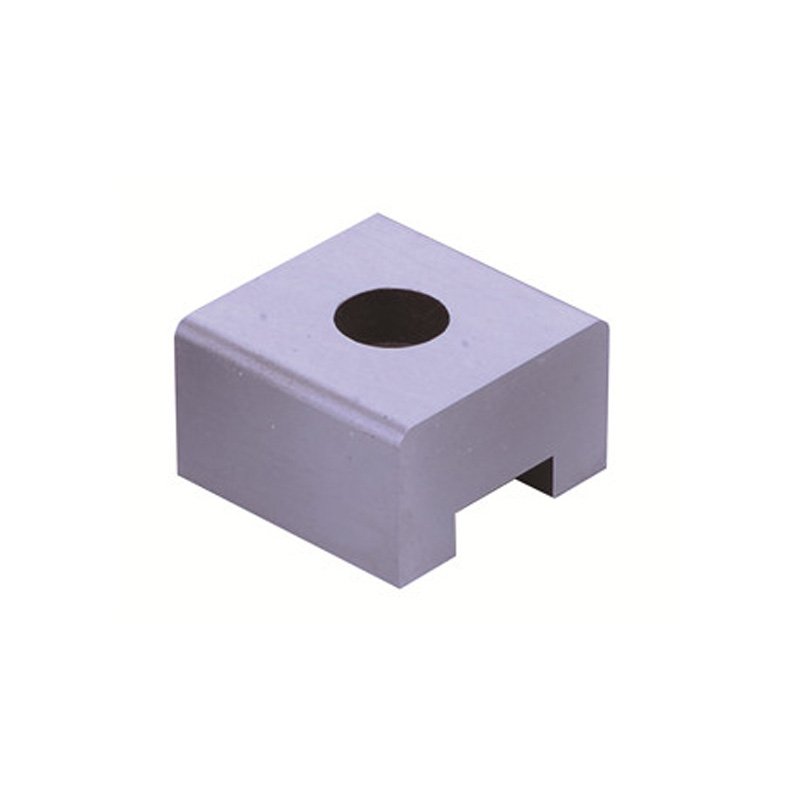

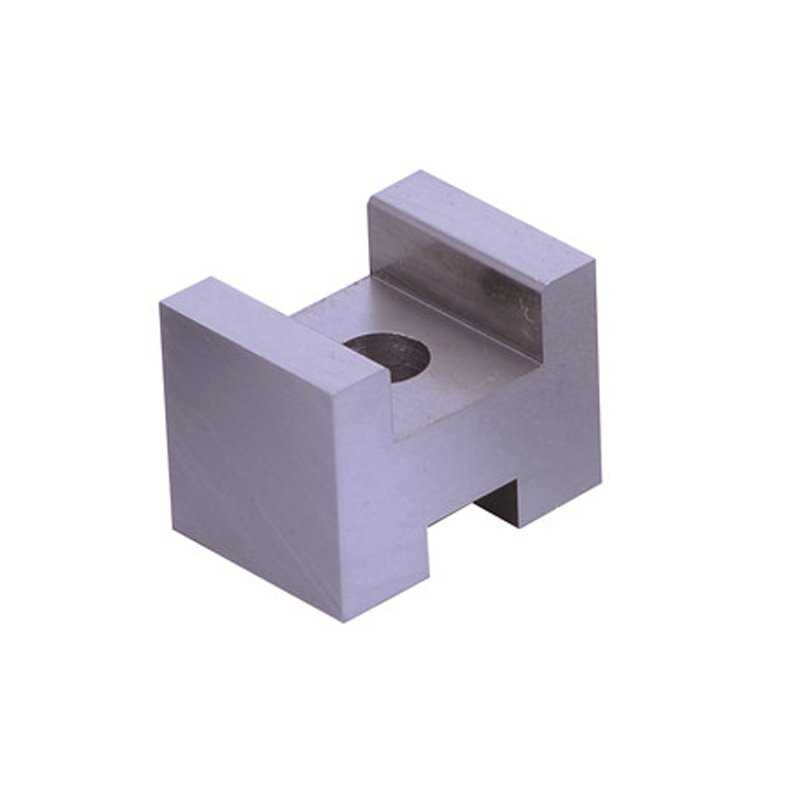

Positioning components are critical elements in mechanical engineering, designed to ensure accurate alignment, secure assembly, and repeatable performance in a wide range of applications. These components, which include dowel pins, alignment pins, and custom positioning devices, are essential for maintaining the precision and reliability of machinery and equipment. This article provides an overview of positioning components, their types, applications, and key considerations for selection and use, based on real-world data and examples.

What Are Positioning Components?

Positioning components are mechanical parts used to align and secure components in a precise position during assembly or operation. They are typically installed in holes, bores, or grooves to ensure that parts are correctly positioned relative to each other. These components are available in various designs and materials to suit different applications and requirements.

Key Functions of Positioning Components

- Alignment: Ensure precise alignment of components during assembly.

- Load Bearing: Provide support and stability under mechanical loads.

- Repeatability: Enable consistent and repeatable assembly processes.

Types of Positioning Components

Positioning components come in a variety of designs to suit different applications. Below are some of the most common types:

1. Dowel Pins

- Design: Cylindrical pins with a uniform diameter.

- Applications: Used for general alignment and positioning in jigs, fixtures, and machinery.

2. Alignment Pins

- Design: Pins with a tapered or stepped design for precise alignment.

- Applications: Ideal for applications requiring tight fits and easy removal, such as aligning heavy machinery components.

3. Shoulder Pins

- Design: Pins with a stepped diameter, featuring a larger shoulder for added support.

- Applications: Used in assemblies requiring precise axial positioning, such as in automotive transmissions.

4. Grooved Pins

- Design: Pins with grooves or knurls for improved grip.

- Applications: Suitable for applications requiring high retention force, such as in aerospace assemblies.

5. Threaded Pins

- Design: Pins with external or internal threads for secure fastening.

- Applications: Used in assemblies requiring both alignment and clamping force, such as in industrial machinery.

Applications of Positioning Components

Positioning components are used across a wide range of industries and applications, including:

1. Automotive Manufacturing

- Example: In engine assembly, positioning components ensure precise alignment of cylinder heads and blocks.

2. Aerospace

- Example: In aircraft assembly, positioning components are used to align and secure critical components like wing sections and landing gear.

3. Medical Devices

- Example: In surgical instruments, positioning components ensure precise alignment of moving parts.

4. Industrial Automation

- Example: In robotic arms, positioning components align and secure joints and linkages.

5. Consumer Electronics

- Example: In smartphone assembly, positioning components ensure precise alignment of circuit boards and casings.

Selection Criteria for Positioning Components

When selecting positioning components, consider the following factors:

1. Material

- Steel: Offers high strength and durability for heavy-duty applications.

- Stainless Steel: Provides corrosion resistance for harsh environments.

- Aluminum: Suitable for lightweight applications.

- Plastic: Ideal for applications requiring electrical insulation or reduced weight.

2. Tolerances

- Precision: Ensure the components meet the required dimensional and geometric tolerances for your application.

- Surface Finish: Consider the surface finish to reduce friction and wear.

3. Load Requirements

- Axial Loads: Choose components with sufficient strength to withstand axial forces.

- Radial Loads: Ensure the components can handle radial forces without deformation.

4. Environmental Conditions

- Temperature: Select materials that can withstand the operating temperature range.

- Corrosion: Choose corrosion-resistant materials for harsh environments.

Installation and Maintenance Tips

1. Installation

- Tools: Use appropriate tools like arbor presses or hydraulic presses for safe and efficient installation.

- Alignment: Ensure the component is properly aligned during installation to prevent misalignment.

2. Maintenance

- Inspection: Regularly check for signs of wear, deformation, or corrosion.

- Replacement: Replace components that show signs of damage or wear to prevent failure.

Common Issues and Solutions

1. Wear and Tear

- Issue: Components may wear out over time due to friction and load.

- Solution: Choose materials with high wear resistance and perform regular maintenance.

2. Corrosion

- Issue: Steel components may corrode in harsh environments.

- Solution: Use stainless steel or coated components for corrosion resistance.

3. Improper Fit

- Issue: Components may not fit securely if the dimensions are incorrect.

- Solution: Verify dimensions and tolerances during the design phase.

Conclusion

Positioning components are indispensable elements in mechanical systems, providing precise alignment and secure assembly for a wide range of applications. By understanding the different types, selection criteria, and maintenance practices, you can ensure optimal performance and longevity of your assemblies. Whether you’re working in automotive manufacturing, aerospace, or consumer electronics, positioning components are a critical part of your success.