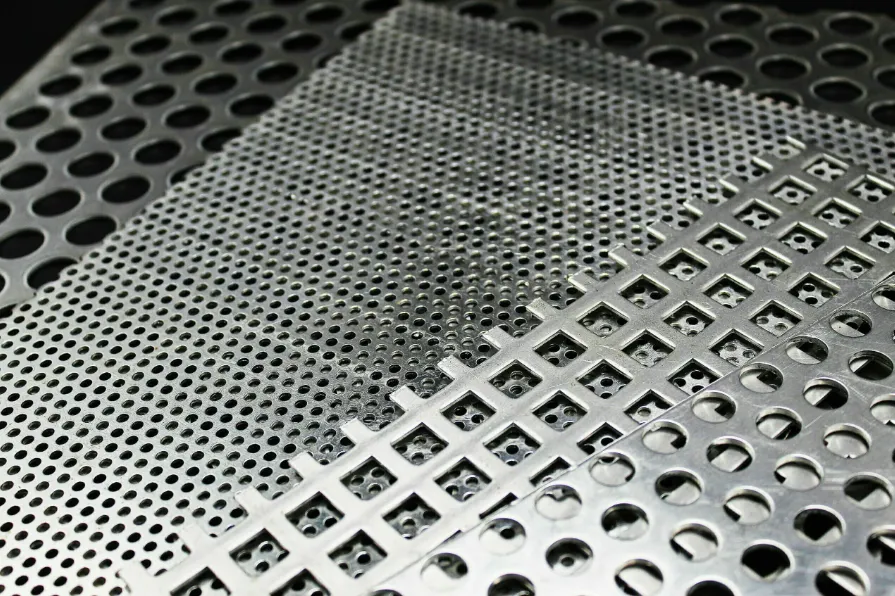

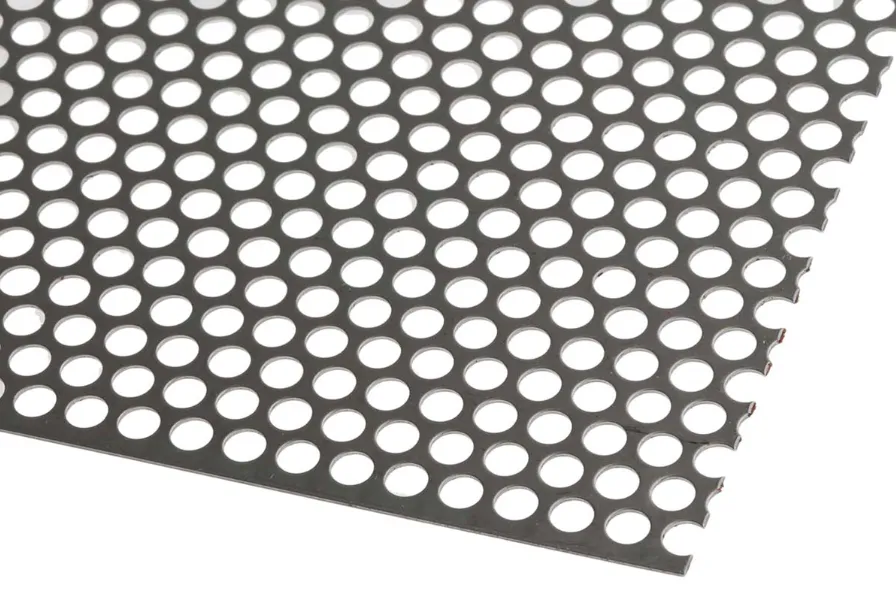

Perforated metal sheets have become indispensable across industries, offering an optimal balance of strength, airflow, and design flexibility. Modern manufacturing techniques can produce holes as small as 0.3mm diameter with ±0.02mm positional accuracy in stainless steel sheets up to 6mm thick. The architectural sector particularly benefits from this precision, where 304-grade stainless steel panels with 2mm holes at 60% open area provide both structural integrity (yield strength 205 MPa) and 85% visible transparency for building facades.

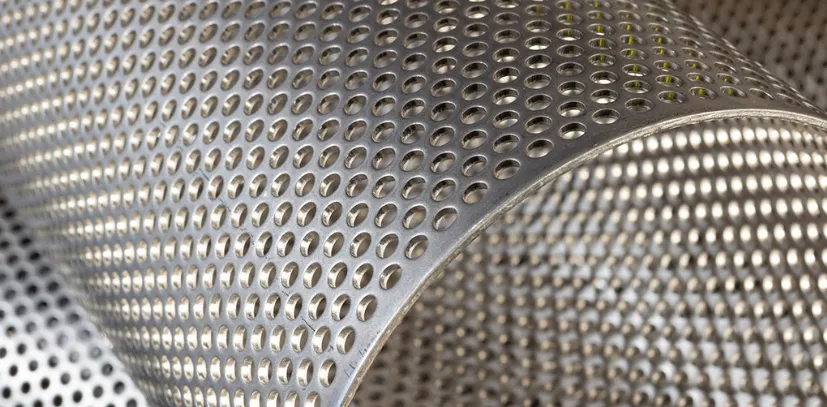

Material science advancements have expanded perforated metal applications dramatically. Aluminum 5052 sheets with hexagonal perforations demonstrate 40% greater strength-to-weight ratio than solid panels when used in transportation flooring, while maintaining 70% open area for drainage and ventilation. In industrial settings, galvanized steel sheets with 5mm round holes arranged in staggered patterns show 300% better debris-shedding capability compared to woven mesh, crucial for mining and agricultural machinery filters.

Material science advancements have expanded perforated metal applications dramatically. Aluminum 5052 sheets with hexagonal perforations demonstrate 40% greater strength-to-weight ratio than solid panels when used in transportation flooring, while maintaining 70% open area for drainage and ventilation. In industrial settings, galvanized steel sheets with 5mm round holes arranged in staggered patterns show 300% better debris-shedding capability compared to woven mesh, crucial for mining and agricultural machinery filters.

The manufacturing process itself has evolved significantly. Contemporary CNC punching machines like the Trumpf TruPunch 5000 can perforate up to 900 holes per minute in 3mm mild steel with positional repeatability of ±0.1mm. Laser perforation systems take this further, creating micro-perforations (0.5-1.0mm) in copper sheets for electronics cooling applications, achieving thermal transfer coefficients 25% higher than traditional drilled solutions.

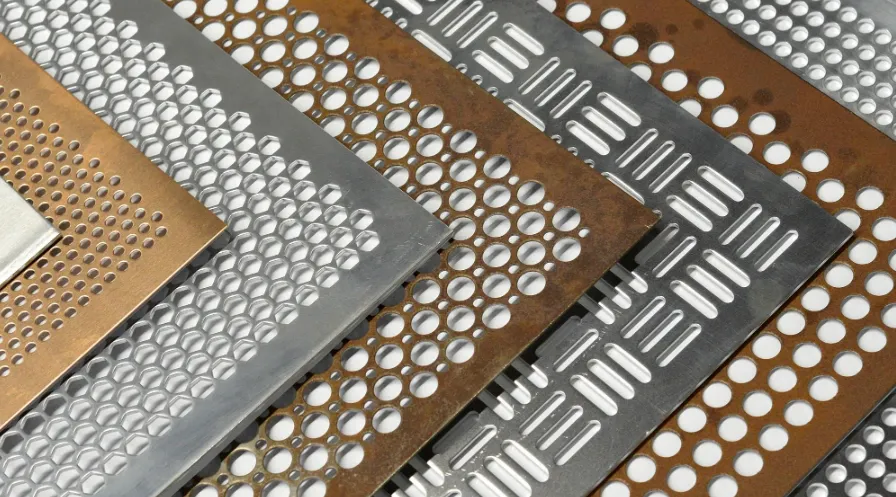

Specialized applications demand unique perforation patterns. Pharmaceutical companies now use 316L stainless steel sheets with 0.4mm holes (0.6mm pitch) for tablet coating machines, providing 92% open area while withstanding CIP (Clean-in-Place) sanitization at 140°C. The automotive industry employs tailored perforation designs – BMW’s acoustic louvers feature variable hole sizes (3-8mm) that reduce wind noise by 4dB while maintaining required airflow for radiator cooling.

Quality control has reached new levels with vision systems that inspect every hole at production line speeds. Current optical measurement systems can detect burrs as small as 0.05mm and hole diameter deviations exceeding ±0.03mm, ensuring compliance with medical device standards where perforated titanium sheets serve as bone growth matrices in spinal implants.

Emerging applications continue to push boundaries. NASA recently developed aluminum perforated sheets with gradient hole patterns (1-3mm) for rocket engine acoustic suppression, demonstrating 30% better damping characteristics than previous designs. In renewable energy, perforated zinc sheets with hydrophobic coatings are increasing solar panel efficiency by 2-3% through optimized airflow and self-cleaning properties.

From architectural masterpieces to life-saving medical devices, perforated metal sheets continue to prove their versatility – not just as industrial components, but as engineered solutions that combine precise functionality with aesthetic possibilities. The future promises even greater innovation as computational fluid dynamics and generative design algorithms create optimized perforation patterns for applications we’ve yet to imagine.