In the ever-evolving landscape of manufacturing, the quest for efficiency and precision has led to the continuous development of machining techniques. Among these, peel milling has emerged as a particularly potent method that combines versatility with advanced performance characteristics. This article delves deep into the concept of peel milling, its operational principles, advantages, applications, and future potential in various industries.

What is Peel Milling?

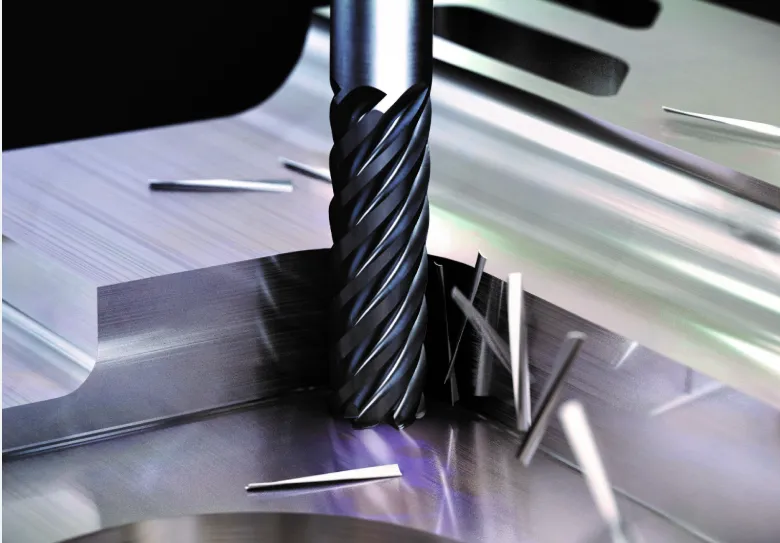

Peel milling is a machining process that utilizes a specialized milling strategy to achieve high material removal rates while maintaining precision. It involves a combination of high axial depth of cut with minimal radial engagement. Typically, this means that the cutter engages the material with a depth that can go up to the maximum cutting depth of the tool, while the width of the cut remains shallow, often between 5% to 10% of the tool’s diameter. This unique approach enables manufacturers to achieve both roughing and finishing operations in a single pass, thus enhancing efficiency significantly.

The core operation of peel milling distinguishes it from traditional milling. In traditional milling, larger radial depths can lead to higher cutting forces, which can affect tool life and increase cycle times. Peel milling, by contrast, minimizes these mechanical stresses by ensuring that the cutter’s engagement with the workpiece remains consistent and controlled.

The tool path in peel milling is typically defined by a trochoidal motion, where the cutter moves in a circular or elliptical manner while simultaneously advancing along the workpiece. This method not only reduces wear on the tool but also allows for higher speeds and feeds, compounding the efficiency benefits.

Advantages of Peel Milling

1. Reduced Cutting Forces

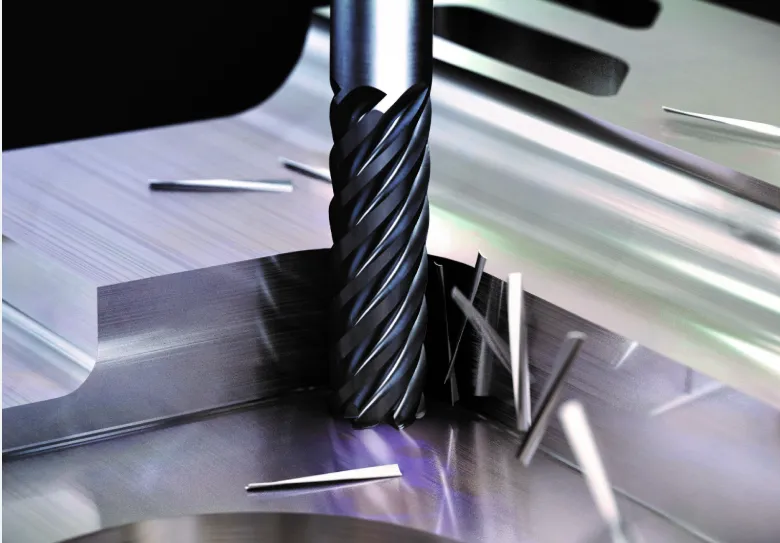

One of the most significant advantages of peel milling is its reduction of cutting forces, particularly the radial forces exerted on the tool. This ultimately translates to lower tool wear rates and the potential to utilize a more aggressive machining strategy. Operators can push the limits of cutting speeds and feeds without the associated risk of tool failure.

2. Enhanced Tool Life

The dispersal of cutting forces across the tool contributes to a longer lifespan. Since the wear is uniform along the flute of the cutting tool, surgeons can utilize peel milling techniques in operations involving tough materials, such as hardened steels and superalloys, which are traditionally challenging to machine effectively.

3. Increased Productivity

Peel milling can efficiently transition between roughing and finishing, minimizing setup times and maximizing the efficiency of machining operations. By significantly increasing the material removal rates, manufacturers can enhance overall throughput.

4. Versatility

Peel milling is adaptable to a variety of materials, including metals, plastics, and composites. Its effectiveness in both high-hardness and soft materials makes it a versatile choice for manufacturers across different sectors.

Applications of Peel Milling

Peel milling finds applications in a wide range of industries, thanks to its efficiency and precision capabilities. Some of the most notable uses include:

1. Aerospace Industry

In aerospace manufacturing, components often require complex geometries and high accuracy. Peel milling’s precision and ability to handle hard materials make it ideal for machining aircraft components, including turbine blades and structural parts.

2. Automotive Sector

The automotive industry benefits greatly from peel milling, particularly in producing engine parts, gearbox components, and various high-precision fittings. The ability to switch between roughing and finishing in a single operation is invaluable for meeting strict production timelines.

3. Medical Devices

The medical field demands high precision, particularly for surgical instruments and implants. Peel milling is utilized for its ability to maintain tight tolerances while machining intricate shapes in materials like titanium and stainless steel, which are commonly used in medical applications.

4. Mold and Die Manufacturing

In the realm of mold and die production, where precision and surface finish are paramount, peel milling proves its worth by allowing manufacturers to achieve high-quality results in less time.

Future Potential of Peel Milling

As technology advances, the potential for peel milling continues to grow. With the integration of smart machining technologies and Industry 4.0, processes can be monitored and optimized in real-time, ensuring that production remains efficient and adaptive to changing demands.

Moreover, advancements in cutting tool materials and coatings are expected to enhance the performance of peel milling further, allowing for even greater speeds and feeds, as well as improved surface finishes. The combination of these factors could lead to even more widespread adoption of peel milling in various manufacturing sectors.

Conclusion

Peel milling represents a significant advancement in machining technology, offering enhanced efficiency, reduced costs, and improved productivity. As industries continue to prioritize precision and speed, this technique is well-positioned to play a crucial role in the future of manufacturing. By embracing peel milling, manufacturers can not only meet current demands but also innovate and grow in an increasingly competitive landscape. Whether it is in aerospace, automotive, or medical applications, the benefits of peel milling make it a valuable addition to the modern machinist’s toolkit.