Left-handed Milling Cutter

Left-handed milling cutters are typically chosen for high-precision machining needs. They are commonly used in the precision machining of mobile phone buttons, membrane switch panels, LCD panels, acrylic lenses, and other precision components. For high-demand applications, especially in the production and machining of mobile phone buttons or electrical panels, where high precision and smoothness are required, down-cutting left-hand rotation milling cutters are selected to avoid white edges on the cutting edge and burrs on the machined parts.

(3) Keyway Milling Cutter: Used for milling keyways and the like.

(4) Slot Milling Cutter and Saw Blade Milling Cutter: Used for milling various slots, sides, step faces, and sawing, etc.

(5) Special Slot Milling Cutter: Used for milling various special slot shapes, including shaped slot milling cutters, half-moon keyway milling cutters, dovetail slot milling cutters, etc.

(6) Angle Milling Cutter: Used for milling straight grooves, spiral grooves, etc., on milling tools.

(7) Mold Milling Cutter: Used for milling various mold convex and concave forming surfaces.

(8) Grouped Milling Cutter: Several milling cutters are combined into one group for milling complex forming surfaces, different surfaces of large parts, and wide surfaces, etc.

Shovel-tooth Milling Cutter: Some milling cutters require reshaping before grinding, maintaining their original shape. They are shaped with shovel teeth at the back, including disc groove milling cutters, convex semi-circular, concave semi-circular milling cutters, double-angle milling cutters, forming milling cutters, etc.

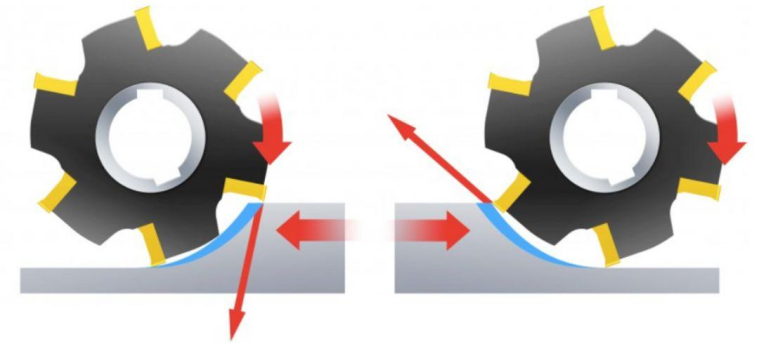

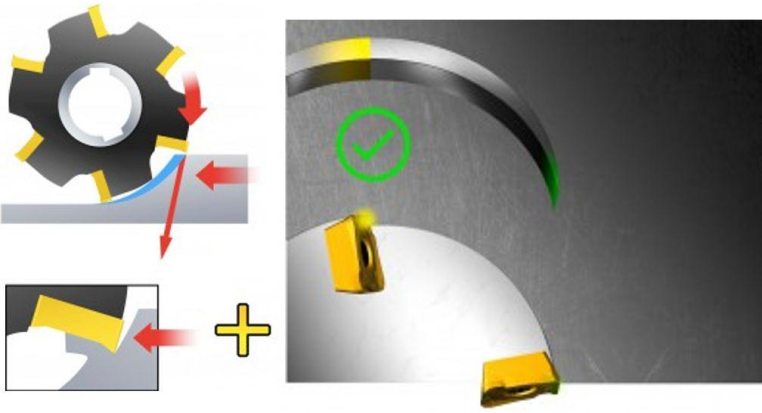

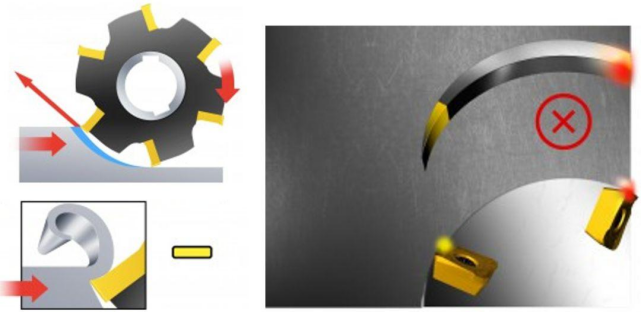

Climb Milling and Conventional Milling

There are two ways relative to the feed direction of the workpiece and the rotation direction of the milling cutter:

The first is climb milling, where the rotation direction of the milling cutter is the same as the feeding direction. The milling cutter grabs the workpiece and cuts the final chips at the beginning of the cut.

The second is conventional milling, where the rotation direction of the milling cutter is opposite to the feeding direction. The milling cutter must slide on the workpiece before starting the cut, starting with zero cutting thickness and reaching maximum cutting thickness at the end of the cut.

01 Milling Machining Methods

- Basic Milling: Includes plane milling, slot milling, side milling, and contour milling.

- Advanced Milling: Includes ramp milling, thread interpolation, trochoidal milling, push-pull contour milling, slotting, contour parallel milling, drilling.

02 Definition of Milling Machining Strategies

(1) Conventional Machining:

A strategy for general-purpose machining. The ratio of cutting width to cutting depth can vary depending on the type of operation.

- Tool Characteristics: Tools have relatively long cutting edges and small core diameters, with no high precision requirements.

- Machine Requirements: No special requirements.

- Application Areas: Basic CNC technology is available; advanced machining methods are not feasible; metal removal rates can only reach a moderate level; applications typically include small batch production and a wide range of materials.

(2) High-Speed Machining:

A strategy that combines small radial cutting depths with high cutting and feed speeds; can achieve high material removal rates and low Ra values. Typical characteristics include low cutting forces, less heat transferred to the tool and workpiece, reduced burr formation, and high dimensional accuracy.

- Tool Characteristics: Stable (with a larger core diameter and shorter cutting length), clear and well-formed chip space, conducive to good chip evacuation, coatings.

- Machine Requirements: High-speed CNC control, high spindle speeds, fast table feed rates.

- Application Areas: Semi-finishing and finishing of hardened steels (48-62 HRC) in the mold industry, with short lead times. When used with the correct tools and advanced machining methods, this technique can also be applied to many other materials.

(3) High-Performance Machining:

A strategy that can achieve very high material removal rates. Typical characteristics include a cutting width of 1 times the cutter diameter and a cutting depth of 1 to 1.5 times the cutter diameter, depending on the workpiece material.

- Tool Characteristics: Special chip space structure developed on the tool’s chip groove, 45° tool tip, small plane or tool tip arc for protection, specially smooth chip space, coatings, with or without side clamping handle.

- Machine Requirements: High stability, high power requirements, high rigidity clamping system.

- Application Areas: Production efficiency is key in large-scale production machining, or for single-piece products with high metal removal rate requirements. (4) High-Feed Machining: A strategy that combines full-diameter cutting and small cutting depths with high feed rates. Can achieve high metal removal rates and good surface roughness.

- Tool Characteristics: Specially developed tool tips, extremely short cutting lengths, coatings.

- Machine Requirements: High stability, possibility of high feed rates.

- Application Areas: From soft steel to hardened steel, titanium alloys, and stainless steel, it is excellent as a pre-machining step before high-speed machining. It can also be used for deep cavity machining. One of the advantages of this technique is its ease of use for simple, safe, and fast programming in CAM. Using the so-called contour parallel milling strategy, it is easier to program complex shapes without extensive programming experience. (5) Micro Machining: A machining strategy using extremely small cutter diameters.

- Tool Characteristics: Diameter range from Ø0.1 to 2.0mm, short cutting length, wide range of outer circle diameter reductions, high precision, coatings.

- Machine Requirements: High spindle accuracy, high speeds, CNC, thermal stability to prevent spindle elongation.

- Application Areas: Various cavity machining on many types of materials.

03 Milling Summary

- Check the machine tool power and rigidity to ensure that the tool diameter used can have the shortest possible tool overhang on the machine tool.

- The number of teeth of the milling cutter is moderate to ensure that there is not too much tool engagement with the workpiece at the same time during machining to prevent vibration. Sufficient tool engagement with the workpiece is required when milling narrow workpieces or cavities.

- Appropriate feed per tooth to obtain good cutting effects when the chip thickness is thick enough to reduce tool wear. Use positive rake angle slot-type tool inserts for smooth cutting effects and minimum power consumption.

- Milling cutter diameter suitable for workpiece width.

- Correct primary clearance angle (45 degrees suitable for general milling).

- Proper milling cutter position.

-

Use cutting fluid only when necessary; dry milling usually results in better tool life.

This article is a repost from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact DSR. We will promptly negotiate copyright issues or delete content.

This article is a repost from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact DSR. We will promptly negotiate copyright issues or delete content.