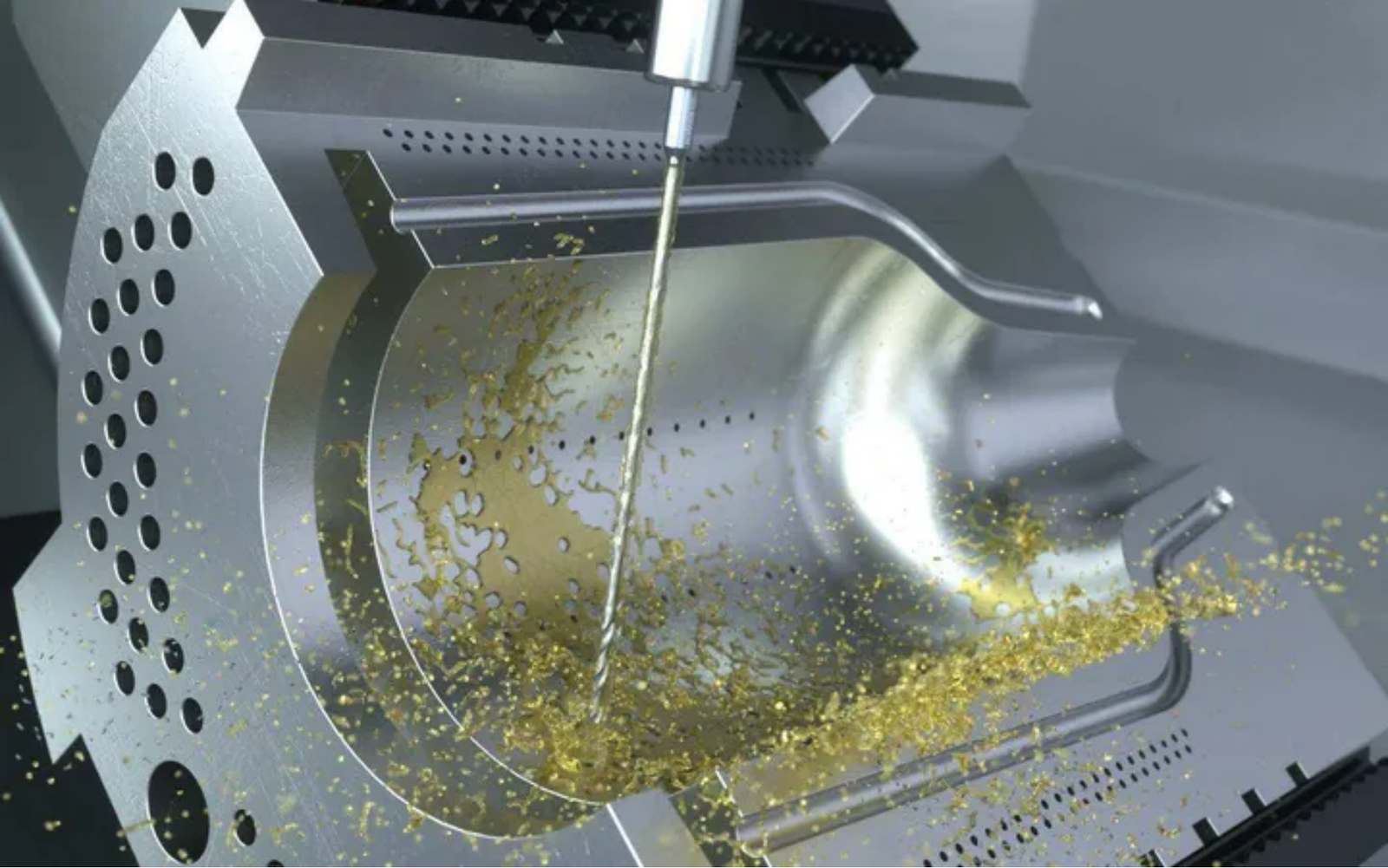

Milling cutters are generally multi-tooth tools. Due to the participation of multiple teeth in cutting simultaneously, with long cutting edges, and the ability to adopt higher cutting speeds, the productivity is high. Different milling cutters can be used to process flat surfaces, grooves, steps, etc., as well as gear teeth, threads, spline shafts, and various forming surfaces.

Structure of Milling Cutters

Taking indexable milling cutters as an example:

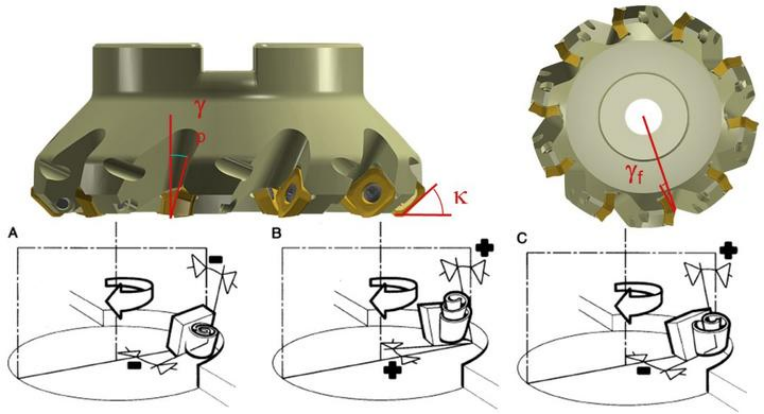

1)Main Geometric Angles

Milling cutters have a main rake angle and two clearance angles, one called the axial clearance angle and the other called the radial clearance angle.

The radial clearance angle γf mainly affects the cutting power; the axial clearance angle γp affects the formation of chips and the direction of axial forces, with positive values of γp causing the chips to fly away from the workpiece surface.

Lead angle (front face contact surface)

Negative lead angle: Used for steel, steel alloys, stainless steel, and cast iron.

Positive lead angle: Used for sticky materials and some high-temperature alloys.

Neutral lead angle: Used for threading, grooving, contour turning, and form cutting.

- Geometry of Milling Cutter

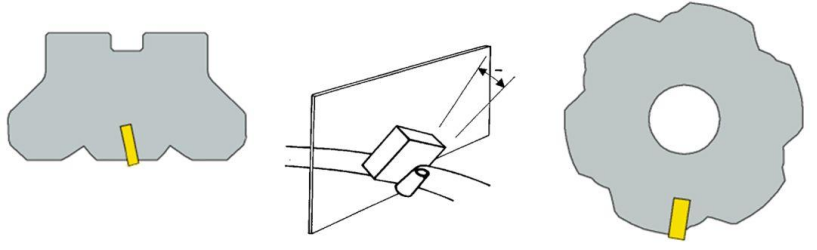

Firstly:Geometry of Milling Cutter

Cutting is light and fast, chip removal is smooth, but cutting edge strength is relatively poor. Suitable for processing soft materials, stainless steel, heat-resistant steel, ordinary steel, and cast iron, etc. This form should be preferred in small power machine tools, insufficient rigidity of process systems, and when chip lumps are generated.

Advantages:

Smooth cutting, smooth chip removal, good surface roughness.

Disadvantages:

Affects cutting edge strength. Not conducive to cutting contact. The workpiece may come off the machine table.

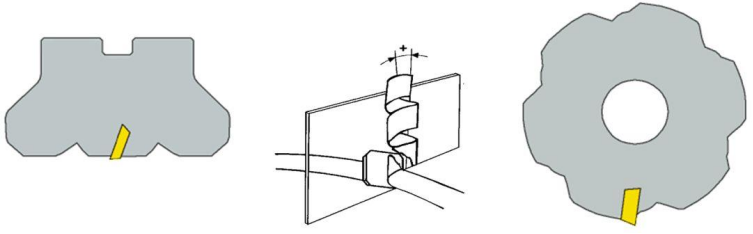

Secondly:Both edges adopt negative angles.

Strong impact resistance, using negative inserts, suitable for rough milling of cast steel, cast iron, and high hardness, high strength steel.

However, milling power consumption is high, requiring excellent rigidity of the process system.

Advantages:

Beneficial for cutting edge strength, increasing productivity, can push the workpiece towards the machine table.

Disadvantages:

Greater cutting force may lead to chip blockage.

Finally: One edge is at a positive angle and the other edge is at a negative angle.

Cutting edge has strong impact resistance and is also sharp. Suitable for machining steel, cast steel, and cast iron. It also performs well during heavy-duty milling.

Advantages:

Smooth chip removal, favorable cutting force, wide application range.

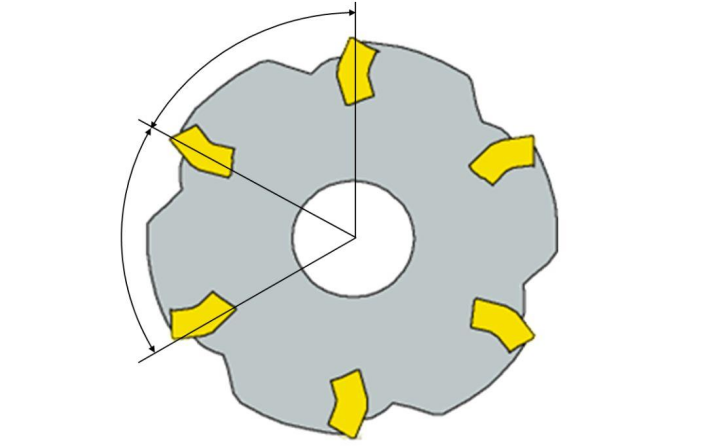

3)Milling cutter pitch

1)Dense teeth: High feed rate, high milling force, small chip space.

2)Standard teeth: Normal feed rate, milling force, and chip space.

3)Sparse teeth: Low feed rate, small milling force, large chip space.

If the milling cutter is not equipped with a dedicated finishing insert, the surface roughness depends on whether the feed per revolution exceeds the width of the insert’s finishing plane.

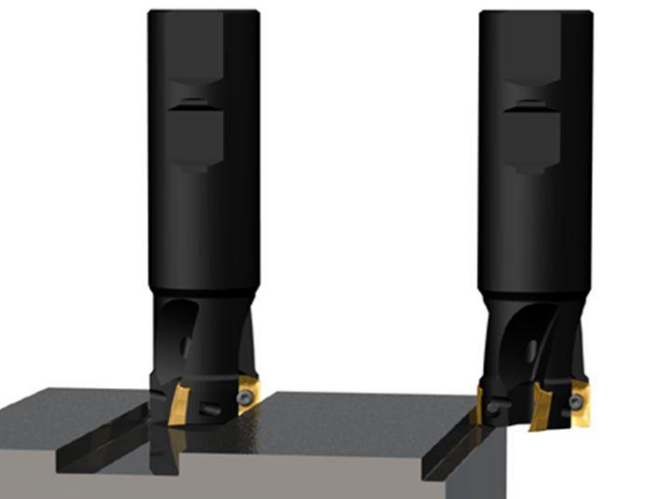

Example: Slot milling & contour milling

Teeth Number:

- Sparse or standard teeth are used for slot milling (safety).

- Dense teeth are used for contour milling (productivity).

Types and Applications of Milling Cutters:

Milling cutters can be classified into end mills and slab mills based on the tooth structure. According to the relative position of the teeth and the axis of the milling cutter, they can be divided into cylindrical milling cutters, angular milling cutters, face milling cutters, and form milling cutters. Based on the shape of the teeth, they can be classified into straight-tooth milling cutters, spiral-tooth milling cutters, helical-tooth milling cutters, and curved-tooth milling cutters. According to the structure of the tool, they can be divided into integral milling cutters, combination milling cutters, sets or kits of milling cutters, insert milling cutters, machine-clamped welding milling cutters, and indexable milling cutters. However, they are usually classified based on the machining form of the back of the cutting teeth.

End mills can be divided into the following categories:

(1) Face Milling Cutters: including integral face milling cutters, insert face milling cutters, and machine-clamped indexable face milling cutters, used for rough, semi-finish, and finish machining of various flat surfaces, step surfaces, etc.

(2) End Mills: used for milling step surfaces, side surfaces, grooves, recesses, holes of various shapes on workpieces, and internal and external curved surfaces. End mills can be broadly categorized into left-hand and right-hand rotation types. Many people still have no concept of left-hand and right-hand rotation.

Right-hand Rotation End Mill:

Firstly, whether a tool is left-hand or right-hand rotation can be determined as follows: facing a vertical milling cutter, if the flute rises from the lower left to the upper right, it is right-hand rotation; if the flute rises from the lower right to the upper left, it is left-hand rotation. Right-hand rotation can also be determined using the right-hand rule: the curved fingers represent the rotation direction, and the raised thumb represents the upward direction, indicating right-hand rotation. The helical flute serves the purpose of chip evacuation and also constitutes the front angle and the front portion of the milling cutter.