Micro machining is a specialized field of manufacturing that focuses on the production of incredibly small parts and features, typically measured in micrometers (one-millionth of a meter). This technique plays a crucial role in various industries, including electronics, medical devices, aerospace, and automotive, where precision is paramount.

1. Key Technologies in Micro Machining

1. Key Technologies in Micro Machining

Micro machining encompasses a range of technologies that enable the production of micro-scale components. Some of the most commonly used processes include:

-

Laser Machining: This method uses focused laser beams to remove material from a workpiece. It offers high precision and the ability to work with a variety of materials, including metals, ceramics, and polymers. Laser machining can achieve intricate patterns and contours at a microscopic level.

-

Electrical Discharge Machining (EDM): In this process, electrical discharges are used to erode material from a conductive workpiece. Micro-EDM is particularly effective for producing complex shapes and tiny features that are difficult to achieve with traditional machining methods.

-

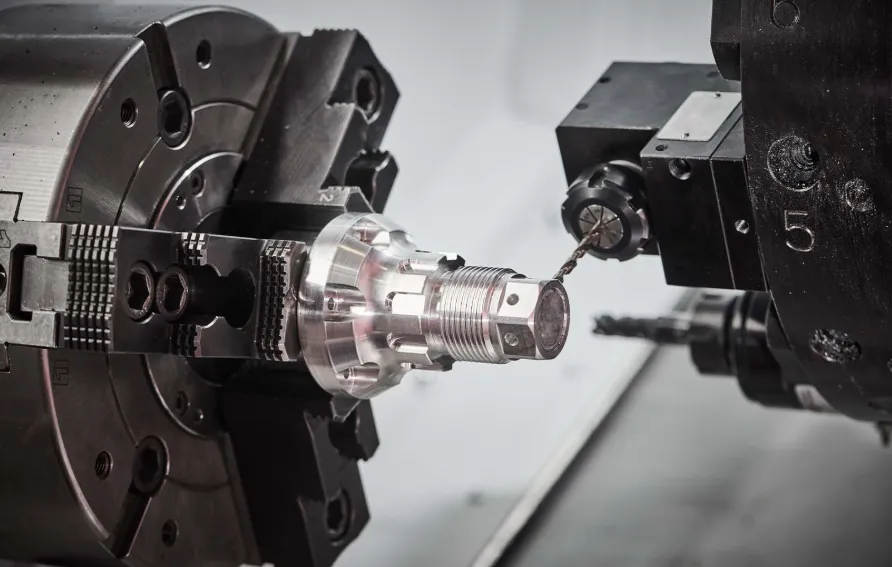

Micro Milling: This technique involves the use of miniature milling machines equipped with precision tools. Micro milling is ideal for producing features like slots, holes, and intricate patterns on small components.

-

Photolithography: Widely used in semiconductor manufacturing, photolithography involves coating a substrate with a photosensitive material, exposing it to light, and then etching away unexposed areas. This method is crucial for producing intricate patterns on microchips.

-

Micro Turning: This process is similar to traditional turning but is adapted for small parts. It enables high precision and fine surface finishes, making it suitable for components like screws and shafts used in watches and medical devices.

2. Applications of Micro Machining

Micro machining finds applications across various industries, each demanding high precision and intricate designs:

-

Electronics: With the trend towards miniaturization, micro machining is essential for manufacturing components such as capacitors, resistors, and more complex devices like MEMS (Micro-Electro-Mechanical Systems), which are used in smartphones, sensors, and actuators.

-

Medical Devices: The production of implantable devices, surgical instruments, and diagnostic tools often requires components that are both small and highly precise. Micro machining enables the fabrication of such devices while ensuring they meet stringent regulatory standards.

-

Aerospace: Components such as turbines, sensors, and intricate connectors require micro machining to ensure lightweight yet durable parts that can withstand extreme conditions.

-

Automotive Industry: Micro machined parts are increasingly used in critical applications such as fuel injectors, sensors, and other engine components, where precision can significantly affect performance and efficiency.

3. Trends Influencing Micro Machining

The micro machining market is experiencing significant growth, driven by various trends and innovations:

-

Growing Demand for Miniaturization: As electronics continue to become smaller and more powerful, the demand for micro machining increases. This trend is particularly evident in the smartphone industry, where components must fit into ever-tighter spaces.

-

Advancements in Automation and AI: The integration of automation and artificial intelligence into micro machining processes is enhancing precision and efficiency. Smart machining systems can optimize tool paths, reduce waste, and improve overall productivity.

-

Emergence of 5-Axis Machining: This technology allows for machining in multiple directions and angles, crucial for producing complex geometries. The increased demand for intricate designs is pushing manufacturers to invest in advanced machining centers.

-

Sustainability Initiatives: With growing environmental concerns, there is a push for more sustainable manufacturing processes. Micro machining methods tend to produce less waste and allow for more efficient use of materials, aligning with sustainability goals.

-

Research and Development in New Materials: Innovations in materials, including composites and advanced alloys, are creating opportunities for micro machining to expand into new areas. The ability to work with novel materials can open up additional applications in various sectors.

4. Market Outlook

According to recent market reports, the global micro machining market is expected to grow significantly in the coming years. It was valued at approximately USD 2.4 billion in 2020 and is projected to reach about USD 3.3 billion by 2025, growing at a compound annual growth rate (CAGR) of around 6.2%. This growth is attributed to the rising demand for high-precision components and the ongoing trend of miniaturization across industries.

Conclusion

Micro machining is a critical technology in today’s manufacturing landscape, enabling the production of precise, small-scale components essential for modern devices and applications. As industries continue to evolve with the demand for smaller, more complex parts, the micro machining market is expected to thrive, driven by technological advancements and innovative applications.