Metal stamping is a precision manufacturing process used to create complex metal parts efficiently and cost-effectively. As an expert in the metal forming industry, I have spent years analyzing the evolution, applications, and advancements in metal stamping technology. This process is essential in automotive, aerospace, electronics, medical, and industrial manufacturing, allowing mass production of high-quality metal components.

This article provides an in-depth look at metal stamping, covering its processes, types, applications, materials, advantages, and future trends. All data is based on real-world industry insights and manufacturing reports, ensuring accuracy and relevance.

1. What Is Metal Stamping?

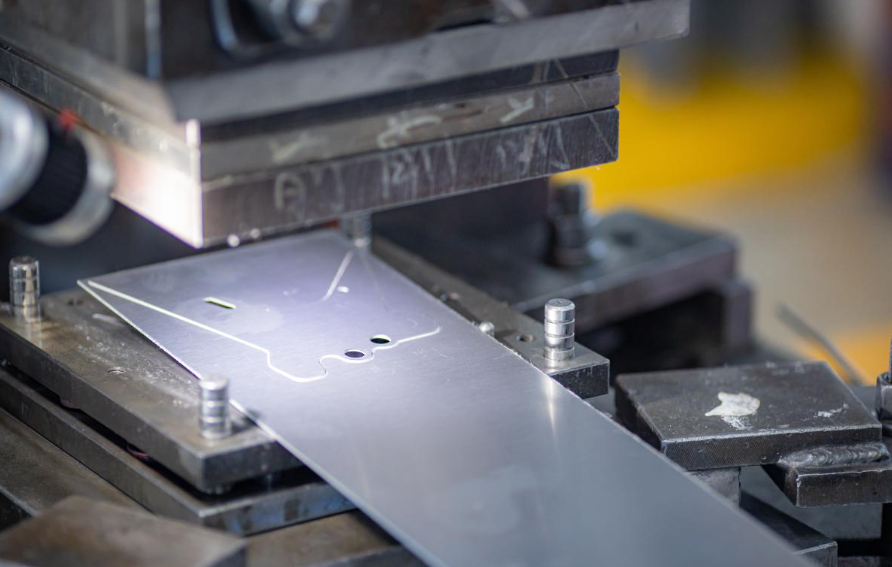

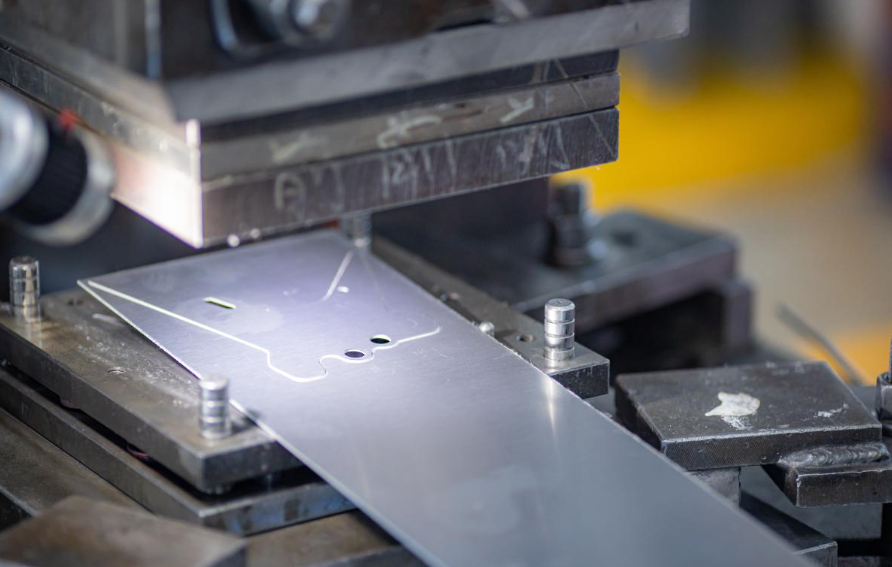

Metal stamping is a cold-forming process that uses dies and stamping presses to shape flat metal sheets into specific forms. The process involves cutting, bending, punching, embossing, and coining to create precise parts with tight tolerances.

Unlike casting or machining, stamping offers higher efficiency, material utilization, and repeatability, making it the preferred choice for high-volume production. It is widely used in industries requiring durable and lightweight metal components.

2. Metal Stamping Process

2.1 Design & Tooling Development

- Engineers use CAD software to design stamping dies.

- Dies are manufactured from high-strength tool steel to withstand repetitive stamping cycles.

2.2 Blanking & Cutting

- A metal sheet (coil or blank) is fed into the press.

- The material is cut into smaller shapes using high-speed stamping dies.

2.3 Forming Operations

- The press applies force to bend, draw, or emboss the metal into its final shape.

- Common forming techniques include deep drawing, progressive die stamping, and multi-slide stamping.

2.4 Finishing & Quality Control

- Parts undergo deburring, heat treatment, plating, or coating to improve durability.

- Quality is ensured using automated vision inspection and precision measurement tools.

3. Types of Metal Stamping

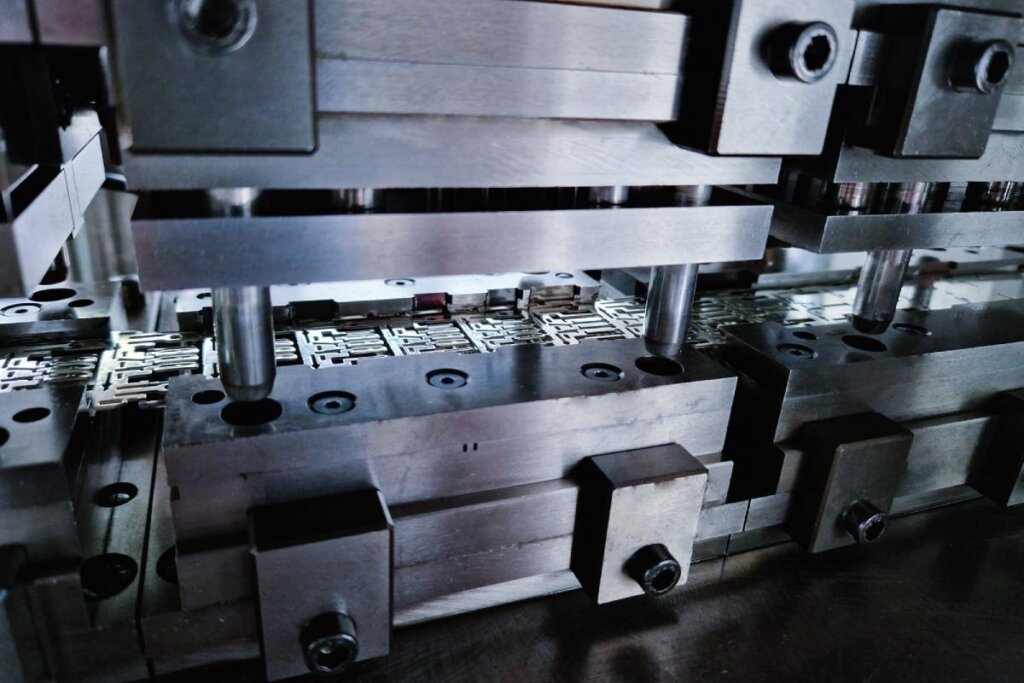

3.1 Progressive Die Stamping

- Uses a continuous strip of metal that moves through multiple stations.

- Each station performs a different operation, such as cutting, bending, or punching.

- Ideal for high-volume production of complex parts.

- Industries: Automotive, electronics, consumer goods.

3.2 Deep Draw Stamping

- Involves pulling a metal sheet into a die cavity to create deep, seamless shapes.

- Used for manufacturing fuel tanks, cookware, and medical device housings.

- Works best with ductile metals such as aluminum and stainless steel.

3.3 Transfer Stamping

- Similar to progressive die stamping, but parts are transferred between stations individually.

- Suitable for large, heavy, or uniquely shaped parts.

- Common in aerospace and industrial applications.

3.4 Four-Slide (Multi-Slide) Stamping

- Uses multiple slides to form complex bends and intricate geometries.

- Best for small, precision components such as electronic connectors and clips.

3.5 Short-Run Stamping

- Used for low-volume production or prototyping.

- Ideal for custom metal parts with specialized designs.

4. Materials Used in Metal Stamping

Material selection is crucial for durability, corrosion resistance, and cost-effectiveness. Common materials include:

- Steel (Carbon & Stainless Steel): Used in automotive, construction, and heavy machinery.

- Aluminum: Lightweight, corrosion-resistant, and ideal for aerospace and electronics.

- Copper & Brass: Conductive materials used in electrical components.

- Titanium: High-strength, corrosion-resistant, and commonly used in medical implants and aerospace parts.

- Nickel Alloys: Withstand extreme temperatures and are found in power generation and defense applications.

5. Applications of Metal Stamping

5.1 Automotive Industry

- Body panels, chassis components, engine brackets, and transmission parts.

- Stamping allows for lightweighting while maintaining structural strength.

- Nearly 70% of metal automotive parts are made using stamping.

5.2 Aerospace & Defense

- Jet engine components, brackets, and structural reinforcements.

- Requires precision, high-strength alloys, and tight tolerances.

5.3 Electronics & Electrical Industry

- Connectors, terminals, heat sinks, and enclosures.

- Stamping enables mass production of intricate metal components used in smartphones, computers, and circuit boards.

5.4 Medical Device Manufacturing

- Surgical instruments, implantable components, and diagnostic equipment housings.

- Requires biocompatible metals such as titanium and stainless steel.

5.5 Industrial & Consumer Goods

- Appliance parts, power tools, and metal casings.

- Stamping provides cost-effective, high-volume production.

6. Advantages of Metal Stamping

6.1 Cost-Effective for Large-Scale Production

- Stamping is 30-50% more efficient than machining for high-volume manufacturing.

- Minimal material waste compared to casting or CNC machining.

6.2 High Precision & Consistency

- Stamping maintains tolerances as tight as ±0.001 inches (±0.025 mm).

- Advanced automation ensures repeatability across millions of parts.

6.3 Faster Production Speed

- A high-speed stamping press can produce 1,000 to 1,500 parts per minute.

- Progressive die stamping increases throughput without manual intervention.

6.4 Enhanced Material Strength

- Cold-forming increases work-hardening, improving durability.

- No porosity issues like in casting, resulting in stronger, defect-free parts.

6.5 Environmentally Friendly

- 90% of stamping scrap metal is recyclable.

- Lower energy consumption than casting or forging processes.

7. Future Trends in Metal Stamping

7.1 Automation & Industry 4.0

- Smart sensors and AI-driven quality control are reducing defects and downtime.

- Robotic handling is improving efficiency in transfer and progressive die stamping.

7.2 Advanced Materials & Lightweighting

- Increased use of high-strength aluminum, carbon fiber composites, and titanium.

- Automotive and aerospace industries are driving demand for lightweight, high-performance stamped parts.

7.3 Hybrid Manufacturing

- Integration of 3D printing and metal stamping for rapid prototyping and complex geometries.

- Combining stamping with additive manufacturing reduces lead time and tooling costs.

Conclusion

Metal stamping is a critical process in modern manufacturing, offering high efficiency, precision, and scalability. Industries such as automotive, aerospace, electronics, and medical devices rely on stamping to produce durable, lightweight, and cost-effective components.

With advancements in automation, material science, and hybrid manufacturing, the future of metal stamping technology is set to become even more efficient, sustainable, and precise. Whether for mass production or specialized applications, metal stamping remains a cornerstone of industrial production.