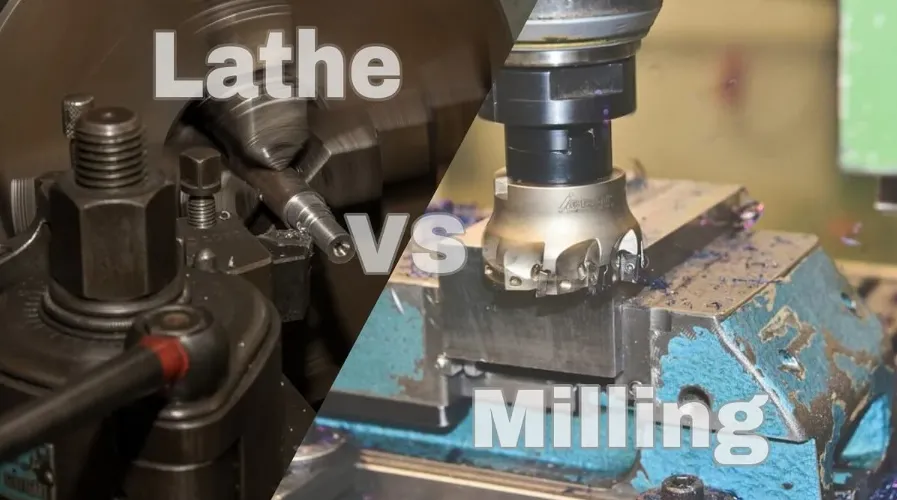

In the world of manufacturing, machining plays a crucial role in producing precise components and parts. Two of the most commonly used machine tools in this process are the lathe and the milling machine. While they serve distinct functions in shaping materials, understanding their differences, applications, and operational principles is essential for anyone involved in manufacturing or mechanical engineering.

What is a Lathe?

A lathe is a machine tool that rotates a workpiece against a cutting tool. The primary operation of a lathe is to remove material from the outside or inside of the workpiece to create cylindrical shapes. It is widely used for turning, drilling, and threading operations.

Key Features of a Lathe:

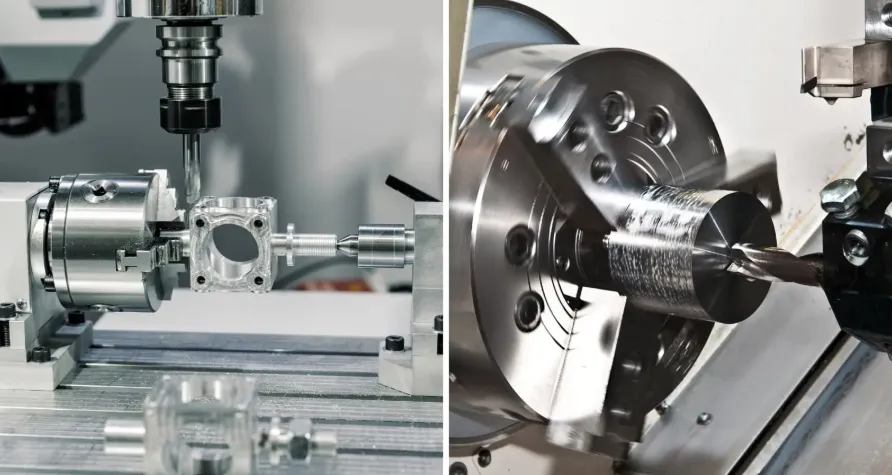

- Rotation of Workpiece: The workpiece is held on a spindle and rotated at high speeds.

- Fixed Cutting Tool: The cutting tool is stationary and moves linearly into the rotating workpiece to remove material.

- Types of Lathes: Various types exist, including engine lathes, turret lathes, and CNC lathes, catering to different machining needs.

Applications of Lathes:

- Manufacturing Cylindrical Parts: Commonly used to produce shafts, pins, and bushings.

- Thread Cutting: Essential for creating screw threads on bolts and nuts.

- Precision Work: Ideal for intricate designs requiring smooth finishes and high roundness.

What is a Milling Machine?

A milling machine, on the other hand, is designed for cutting and shaping various materials via a rotating cutter. Unlike lathes, milling machines work primarily on stationary workpieces, with the cutter moving across the material to remove excess material and craft complex shapes.

Key Features of a Milling Machine:

- Rotating Cutting Tool: The cutter spins at high speeds while the workpiece is held stationary or moved along multiple axes.

- Versatile Operations: Capable of performing various milling operations, including face milling, edge milling, and groove cutting.

- Types of Mills: Includes vertical mills, horizontal mills, and CNC mills for automated, high-precision tasks.

Applications of Milling Machines:

- Manufacturing Flat Surfaces: Widely used for producing machined surfaces such as flat, contoured, or irregular shapes.

- Creating Complex Geometries: Ideal for parts that require intricate cutting and shaping.

- Tool and Die Making: Commonly used in producing molds and dies for manufacturing processes.

Key Differences Between Lathe and Mill

-

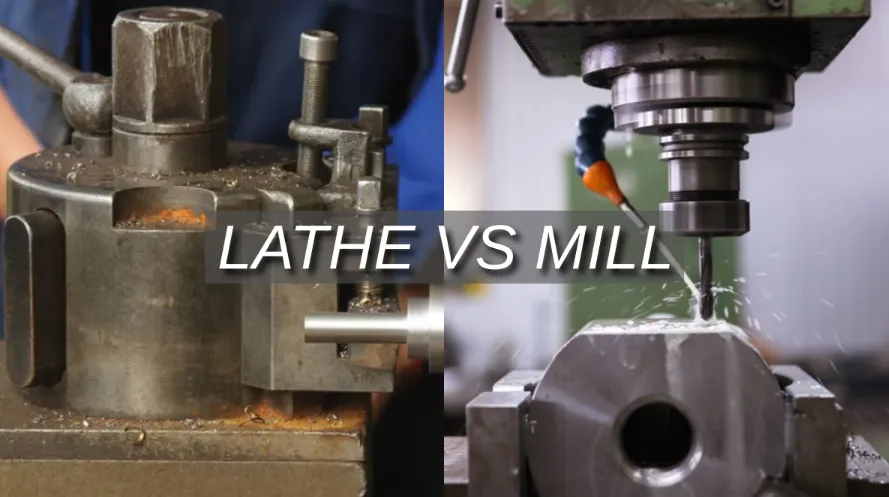

Functionality:

- Lathe: Primarily used for shaping materials into cylindrical forms through rotation.

- Mill: Employed for cutting and shaping materials into intricate or flat forms with a rotating cutter.

-

Workpiece Movement:

- Lathe: The workpiece rotates while the cutting tool remains stationary.

- Mill: The cutting tool rotates while the workpiece is moved along various axes.

-

Types of Cuts:

- Lathe: Mainly capable of creating cylindrical shapes, threads, and grooves.

- Mill: Can produce a wider variety of shapes, including flat surfaces and complex contours.

-

Precision:

- Lathe: Excellent for producing high precision cylindrical parts.

- Mill: Offers high precision for flat and contoured surfaces, making it versatile for various machining tasks.

Choosing Between a Lathe and a Mill

Choosing the right machine tool depends on the specific manufacturing needs:

- If the application involves creating cylindrical shapes or performing operations like threading, a lathe is typically the better choice.

- If intricate shapes, flat surfaces, and complex cutting are required, a milling machine is more suitable.

Conclusion

Both lathes and milling machines serve vital roles in the machining process, each with its unique functionalities and applications. By understanding their differences, manufacturers and machinists can make informed decisions about which tool to use for specific tasks. As technology continues to advance, both lathes and mills are evolving to meet the needs of modern manufacturing, ensuring their place as essential components in the industrial landscape.

Incorporating both lathe and mill processes can enhance production capabilities, offering versatility and precision in creating high-quality components. Whether you’re a seasoned machinist or a newcomer to the field, mastering the use of these machine tools is crucial for achieving optimal results in your projects.