Industrial robots have transformed manufacturing processes across every major industry since their introduction in the 1960s. These programmable mechanical arms now represent a $16.5 billion global market (2023 figures), growing at approximately 12% annually according to the International Federation of Robotics (IFR). Their evolution from simple material handlers to sophisticated, AI-enabled systems has redefined production capabilities worldwide.

Core Components and Specifications

Core Components and Specifications

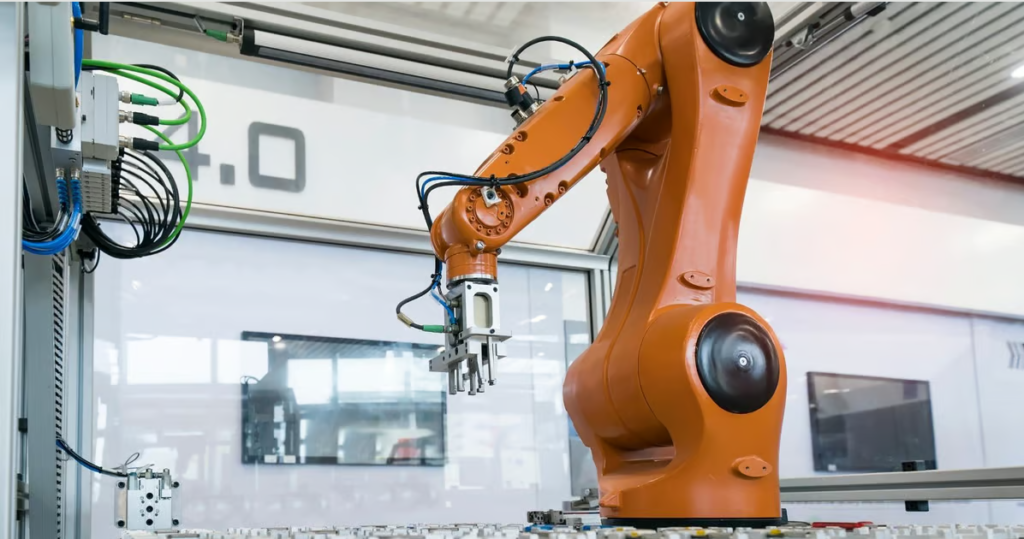

Modern industrial robots consist of several precision-engineered subsystems:

- Manipulator Arm

- Constructed from aircraft-grade aluminum or carbon fiber composites

- 4-7 axes of movement (standard industrial models)

- Reach capabilities from 0.5m (bench-top) to 4.5m (automotive assembly)

- Payload capacities ranging from 500g (electronics) to 2,300kg (heavy machinery)

- Drive Systems

- Servo motors with 0.01mm positional accuracy

- Harmonic or cycloidal gear reducers (backlash <1 arc-minute)

- Brake systems capable of stopping 500kg payloads within 300ms

- Controller Unit

- Real-time operating systems with 1kHz+ control loops

- Standard interfaces (EtherCAT, PROFINET, DeviceNet)

- Safety-rated monitoring (PLd/SIL2 minimum)

- End Effectors

- Customizable tooling (grippers, welders, dispensers)

- Force-torque sensors (0.1N resolution)

- Quick-change mechanisms (<5 second tool swaps)

Technical Performance Metrics

Current generation industrial robots demonstrate:

- Repeatability: ±0.02mm to ±0.05mm (ISO 9283 standard)

- Maximum speed: 2-4m/s (pick-and-place applications)

- Mean Time Between Failures (MTBF): 70,000-100,000 hours

- Energy consumption: 0.5-5kW during operation

Primary Industrial Applications

- Automotive Manufacturing (35% market share)

- Spot welding: 1,500-2,000 welds per vehicle

- Painting: 95% transfer efficiency vs. 60% manual

- Assembly: 45-second cycle times for door panel installation

- Electronics Production (25% market share)

- PCB population: 25,000 components/hour

- Display handling: <0.5mm placement accuracy

- Testing: 100% inspection coverage

- Metal Fabrication (15% market share)

- Arc welding: 50cm/min travel speed

- Machine tending: 85% equipment utilization improvement

- Deburring: 0.1mm material removal consistency

- Food & Pharmaceutical (10% market share)

- Packaging: 200 picks/minute

- Palletizing: 1,000kg/hour throughput

- Cleanroom operation: ISO Class 5 compatibility

Economic Impact

The adoption of industrial robots has demonstrated measurable benefits:

- Labor productivity: 30-50% increase in output per worker

- Quality improvement: 60-90% defect reduction

- Operating cost: 15-25% reduction versus manual processes

- ROI period: 1.5-3 years for typical installations

Technological Advancements

Recent developments include:

- Collaborative Robots (Cobots)

- Force-limited operation (<150N)

- ISO/TS 15066 safety compliance

- 15% annual growth segment

- Mobile Manipulation

- AGV-mounted systems

- SLAM navigation (±10mm positioning)

- 8-hour battery operation

- AI Integration

- Vision-guided picking (99.5% recognition)

- Predictive maintenance (85% failure anticipation)

- Adaptive path planning

- Digital Twin Technology

- Virtual commissioning (30% faster deployment)

- Process simulation (95% accuracy)

Implementation Considerations

Successful robot deployment requires:

- Workcell Design

- 1.5m minimum safety perimeter

- 20-30% additional floor space for maintenance

- 400V three-phase power (typical)

- Programming Methods

- Teach pendant (80% of installations)

- Offline programming (30% time savings)

- No-code solutions (emerging technology)

- Safety Systems

- Light curtains (Type 4)

- Safety-rated monitored stop (Category 3)

- Emergency stop (60ms response)

Future Outlook

Industry projections indicate:

- 3 million operational units by 2028 (IFR forecast)

- 25% penetration in SMEs (currently <10%)

- Next-generation capabilities:

- Haptic feedback systems

- Self-learning algorithms

- Swarm coordination

Industrial robots continue to evolve from isolated automation islands into interconnected, intelligent production systems. Their expanding capabilities and decreasing costs (average $35,000-$150,000 per unit) ensure they will remain vital tools for achieving manufacturing competitiveness in the coming decades. The ongoing convergence of robotics with IoT, AI, and advanced materials promises to unlock new levels of flexibility and efficiency in industrial automation.