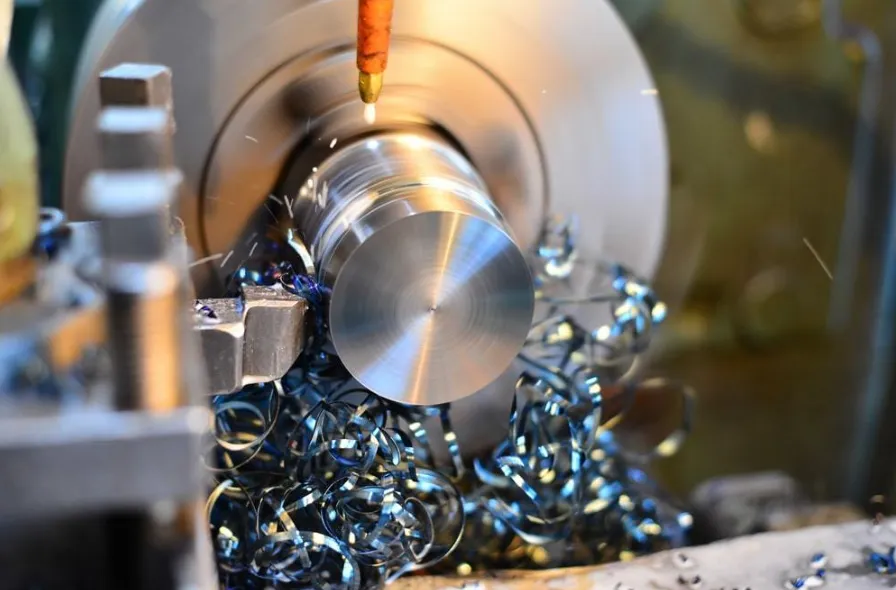

Industrial machining has evolved into a highly sophisticated discipline, combining advanced materials science with digital precision to meet the demands of global manufacturing. Modern CNC machining centers now routinely achieve tolerances of ±0.005 mm (5 microns) on production runs exceeding 10,000 parts, with high-speed spindles reaching 40,000 RPM for aluminum aerospace components. The automotive sector exemplifies this precision, where transmission housings machined from A356-T6 aluminum alloy maintain bore concentricity within 0.01 mm across 500,000-unit production cycles – a critical requirement for electric vehicle reduction gearboxes.

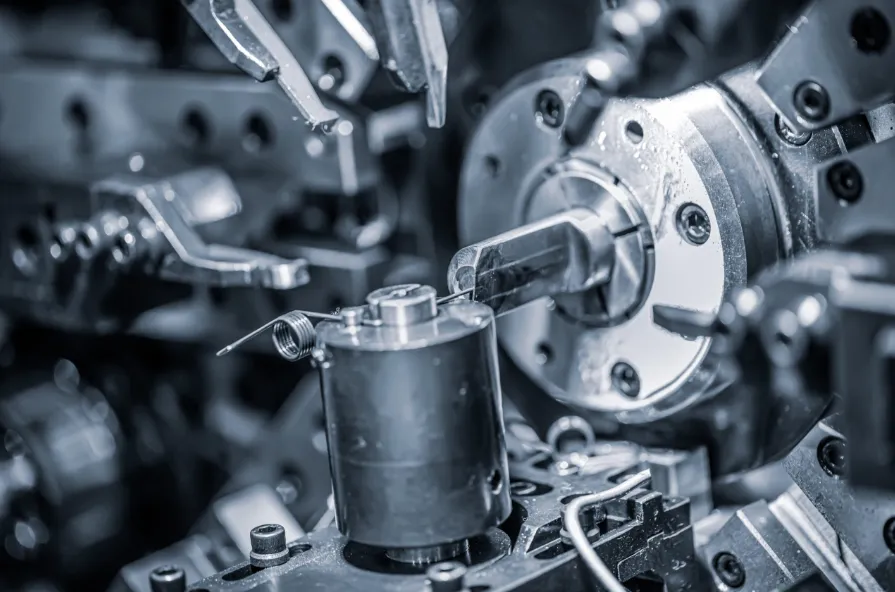

Material innovation drives much of this progress. When machining gamma-prime strengthened nickel alloys like Inconel 738LC for turbine blades, ceramic insert tools now last 8-10 times longer than carbide alternatives at cutting speeds of 90 m/min, thanks to advanced PVD coatings that reduce crater wear by 60%. Similarly, the medical industry benefits from micro-machining capabilities producing cobalt-chrome orthopedic implants with 0.8 μm Ra surface finishes – smoother than polished human bone – using diamond-tipped tools on Swiss-type lathes.

Material innovation drives much of this progress. When machining gamma-prime strengthened nickel alloys like Inconel 738LC for turbine blades, ceramic insert tools now last 8-10 times longer than carbide alternatives at cutting speeds of 90 m/min, thanks to advanced PVD coatings that reduce crater wear by 60%. Similarly, the medical industry benefits from micro-machining capabilities producing cobalt-chrome orthopedic implants with 0.8 μm Ra surface finishes – smoother than polished human bone – using diamond-tipped tools on Swiss-type lathes.

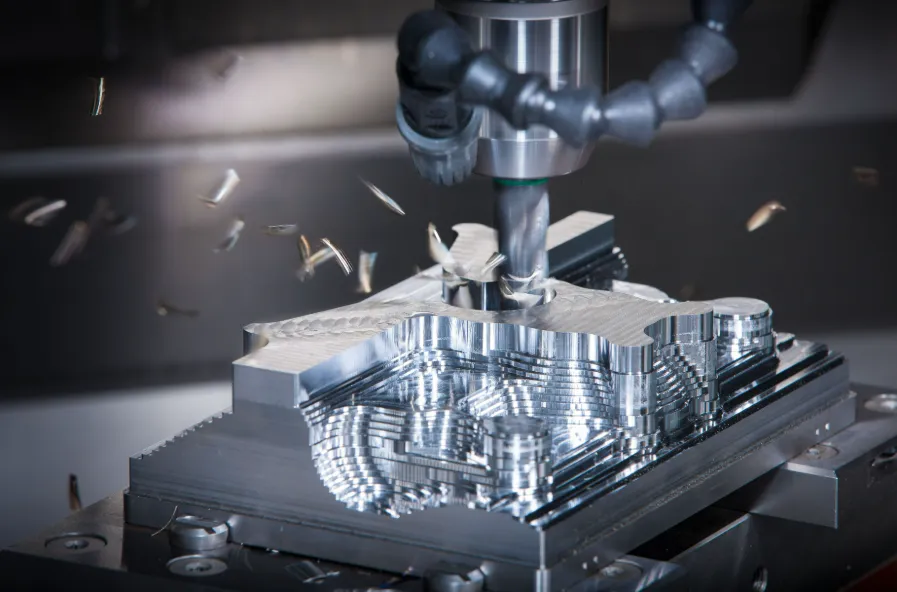

Automation has transformed shop floor efficiency. Robotic tending systems paired with 5-axis machining centers can now produce complex industrial valve bodies in 43% less time than conventional methods, with one operator managing six machines simultaneously. Data from aerospace suppliers shows these automated cells achieve 99.4% first-pass yield rates on titanium structural components, while reducing tooling costs by 35% through predictive analytics that optimize insert replacement timing.

The digital thread connects these physical processes. IoT-enabled machine tools transmit real-time vibration spectra to cloud platforms, where machine learning algorithms detect tool wear patterns 30-40 operating hours before failure occurs. In one automotive case study, this approach reduced unplanned downtime by 78% while improving surface finish consistency by 52% on cast iron brake components.

Emerging hybrid technologies push boundaries further. Laser-assisted machining systems now pre-soften hardened steel (HRC 62) workpieces along the tool path, enabling 300% faster material removal rates for die/mold applications. Meanwhile, additive-subtractive hybrid machines like Mazak’s INTEGREX i-400 AM build near-net-shape Inconel 718 parts via laser deposition before precision machining critical features – reducing material waste from 80% to under 15% compared to traditional billet machining.

As Industry 4.0 matures, industrial machining stands poised for its next revolution – one where self-optimizing machine tools, AI-driven process planning, and sustainable manufacturing practices converge to redefine precision manufacturing for the 21st century.