Industrial automation services have become a pivotal force in transforming the landscape of modern manufacturing. By leveraging advanced technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT), these services enhance efficiency, improve product quality, and reduce operational costs. This article explores the significance of industrial automation services, current market trends, benefits, challenges, and future prospects shaping the industry.

Understanding Industrial Automation Services

Industrial automation services encompass a broad range of solutions aimed at automating various aspects of manufacturing and industrial processes. Key components include:

- Robotic Integration: Deployment and maintenance of robots for tasks like assembly, welding, painting, and material handling.

- Control Systems: Implementation of programmable logic controllers (PLCs) and distributed control systems (DCS) to manage machinery and production lines.

- Software Solutions: Utilization of software for process monitoring, data analysis, and optimization.

- Maintenance and Support: Ongoing technical support, system upgrades, and predictive maintenance to ensure seamless operations.

The primary goal is to minimize human intervention, reduce errors, increase productivity, and lower operational costs.

Market Landscape and Growth

The global industrial automation market has witnessed substantial growth over the past decade. According to Grand View Research, the market was valued at approximately USD 214 billion in 2021 and is projected to reach USD 357 billion by 2026, growing at a compound annual growth rate (CAGR) of around 8.4% during the forecast period. Key drivers contributing to this expansion include:

- Technological Advancements: Innovations in AI, machine learning, and IoT are enabling more sophisticated automation solutions.

- Demand for Efficiency: Industries are striving to enhance operational efficiency and reduce production costs.

- Labor Shortages: The scarcity of skilled labor in manufacturing sectors is pushing companies towards automation.

- Quality and Consistency: Automation ensures higher precision and consistency in production, meeting stringent quality standards.

Benefits of Industrial Automation Services

Implementing industrial automation services offers numerous advantages:

- Increased Productivity: Automated systems operate continuously without fatigue, significantly boosting production rates.

- Enhanced Quality: Precision machinery reduces variability and errors, ensuring consistent product quality.

- Cost Savings: Automation reduces labor costs and minimizes waste, contributing to overall cost efficiency.

- Safety Improvements: Robots handle hazardous tasks, reducing the risk of workplace injuries.

- Data-Driven Insights: Automation systems generate vast amounts of data, enabling informed decision-making and process optimization.

- Scalability: Automated solutions can be easily scaled to meet changing production demands without substantial additional investments.

Key Trends Shaping the Future

Several trends are influencing the direction of industrial automation services:

- Smart Factories: Integration of cyber-physical systems and IoT is leading to the development of smart factories, where machines communicate and collaborate autonomously.

- Edge Computing: Processing data closer to the source reduces latency and enhances real-time decision-making capabilities.

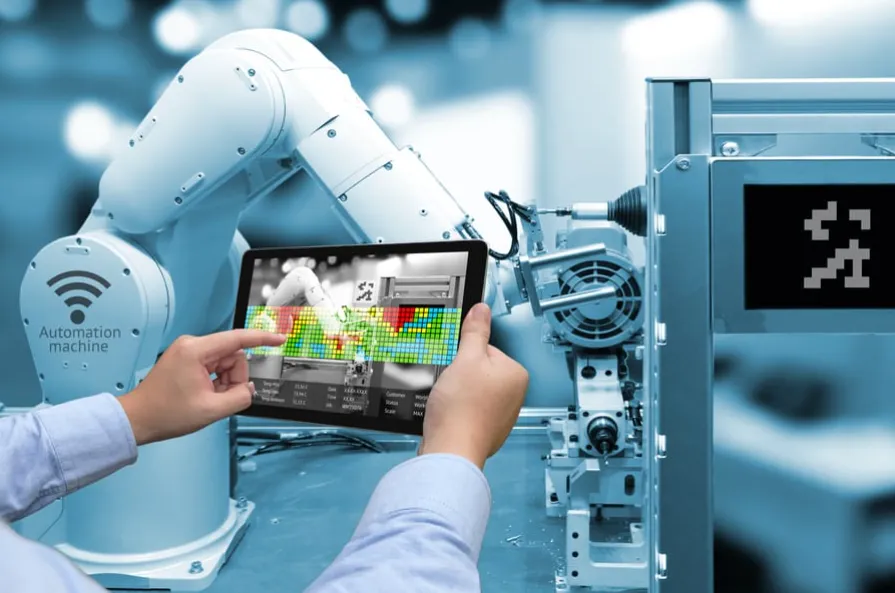

- Collaborative Robots (Cobots): Unlike traditional robots that operate independently, cobots work alongside human workers, enhancing flexibility and productivity.

- Sustainability: Automation is being leveraged to implement energy-efficient practices and reduce the environmental footprint of manufacturing processes.

- Artificial Intelligence and Machine Learning: These technologies enable predictive maintenance, quality control, and adaptive manufacturing processes.

Challenges and Considerations

Despite its benefits, industrial automation faces several challenges:

- High Initial Investment: The upfront costs for automation systems can be substantial, posing a barrier for small and medium-sized enterprises (SMEs).

- Complex Integration: Integrating new automation technologies with existing systems can be complex and requires specialized expertise.

- Cybersecurity Risks: Increased connectivity raises concerns about data security and vulnerability to cyber-attacks.

- Workforce Impact: Automation can lead to workforce displacement, necessitating retraining and upskilling of employees.

Case Study: Siemens’ Digital Enterprise

A notable example of successful industrial automation is Siemens’ Digital Enterprise. Siemens offers comprehensive automation solutions that integrate hardware, software, and services to create fully digitalized production environments. Their solutions enable real-time data analysis, predictive maintenance, and seamless integration across the entire manufacturing process. As a result, clients have reported significant improvements in efficiency, product quality, and operational flexibility.

The Road Ahead

The future of industrial automation services is promising, with continuous advancements poised to further revolutionize manufacturing. Key areas to watch include:

- Advanced AI Integration: Enhanced AI capabilities will lead to more autonomous and intelligent systems capable of self-optimization.

- Digital Twins: Creating virtual replicas of physical assets will enable better simulation, testing, and optimization of manufacturing processes.

- 5G Connectivity: The advent of 5G will facilitate faster and more reliable communication between devices, enhancing automation capabilities.

- Human-Robot Collaboration: Innovations in ergonomics and safety will foster more effective collaboration between humans and robots, maximizing the strengths of both.

Conclusion

Industrial automation services are fundamentally transforming the manufacturing landscape, driving efficiency, quality, and innovation. As technologies continue to evolve, these services will become increasingly integral to industrial operations, enabling businesses to stay competitive in a rapidly changing global market. Embracing automation not only offers immediate operational benefits but also paves the way for sustainable and scalable growth in the future.