CNC machines, or Computer Numerical Control machines, have transformed the way we manufacture parts and components, providing a level of precision and efficiency that is hard to achieve with manual methods. Whether you’re a novice eager to learn or someone familiar with the basics, knowing how to operate a CNC machine effectively is essential for producing quality work. Let’s walk through the steps needed to get started.

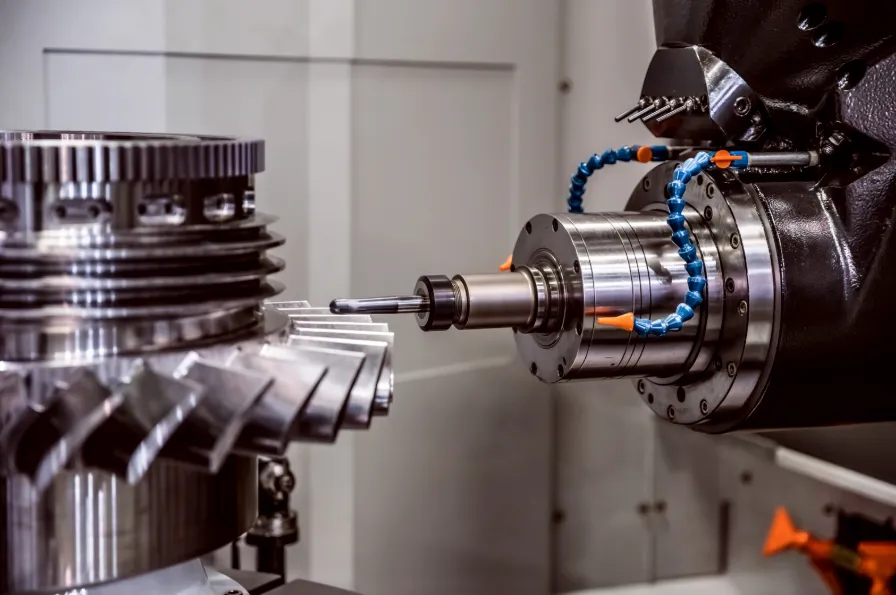

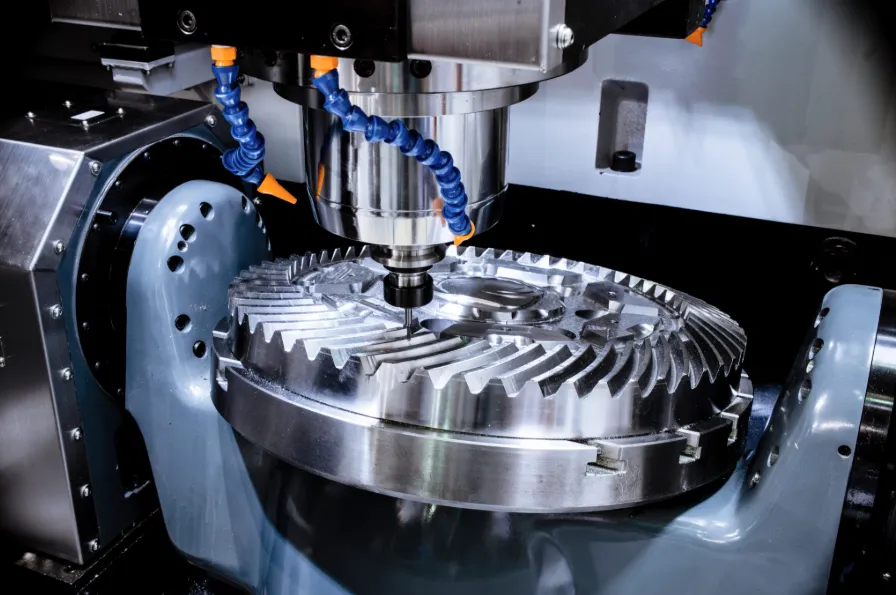

CNC machines come in various forms, including mills, lathes, and plasma cutters, each designed for specific tasks. Regardless of the type, they all operate on the same principle: a computer program directs the machine on how to move and cut material. At the heart of this process is the CNC controller, which receives instructions and translates them into precise movements of the machine’s tool.

Step 1: Prepare Your Workspace and Materials

Before you even touch the machine, it’s important to ensure your workspace is organized and ready. Make sure there’s enough room around the machine to work safely. Clear away any clutter and have all necessary tools and materials at hand. Whether you’re using metal, wood, or plastic, be sure you have the right type and size of material for your project.

Step 2: Design Your Part

The first step in creating anything on a CNC machine is to design the part you want to produce. Most people use CAD (Computer-Aided Design) software for this purpose, such as AutoCAD or SolidWorks. Here, you can create detailed 2D or 3D models of your part. The design is crucial, as it will serve as the blueprint for what the machine will produce.

Step 3: Generate Toolpaths with CAM Software

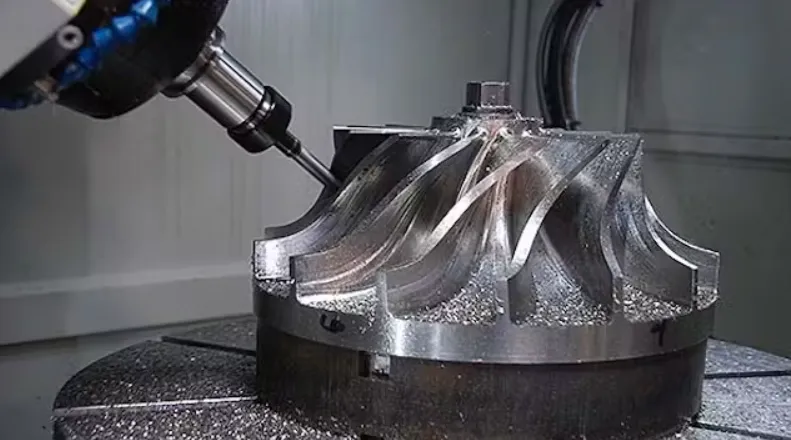

After designing your part, you need to convert that design into a format the CNC machine can understand. This is where CAM (Computer-Aided Manufacturing) software comes in. It takes your CAD design and generates toolpaths, which dictate how the machine will move to create your part. During this step, you set parameters like speed and tool selection to ensure the best results.

Step 4: Set Up the CNC Machine

Now it’s time to prepare the CNC machine for operation. Start by securing your material on the machine bed using clamps or a vise to prevent it from moving. Proper alignment is critical for accuracy, so measure carefully. Next, install the appropriate tools into the machine’s spindle, ensuring they are sharp and suited for the material you’re working with.

Step 5: Input the Program

With the machine set up, you can now input the program that will guide it through the machining process. This typically involves transferring the G-code file from your computer to the CNC machine. Most machines have an easy-to-navigate control panel that helps you load the program and check for any issues before proceeding.

Step 6: Perform a Dry Run

Before you start cutting material, it’s wise to do a dry run. This means running the program without the actual workpiece in place to check for any potential problems. Observing the movements of the machine during a dry run can help you catch any errors that could lead to collisions or other issues.

Step 7: Start Machining

Once everything looks good after the dry run, it’s time to start the actual machining. Pay attention as the machine operates. Listen for unusual noises and watch for erratic movements, as these could indicate problems. Be ready to stop the machine if you notice anything concerning—it’s better to intervene early than to face costly damage.

Step 8: Post-Processing and Cleanup

After the machining is complete and the part is finished, carefully remove it from the machine. Depending on your project, you might need to do some additional work, like sanding or deburring, to get the desired finish. Once you’re done, make sure to clean your workspace and the machine itself, removing any leftover chips and debris to keep everything in good working order.

Safety First

Safety should always be your top priority when working with CNC machines. Wear appropriate personal protective equipment (PPE), including safety glasses and gloves. Familiarize yourself with the machine’s controls and emergency stop buttons before you begin. Always keep your hands clear of moving parts, and avoid distractions while operating the machine.

Final Thoughts

Operating a CNC machine involves a series of carefully planned steps, from design and setup to actual machining and cleanup. By following these guidelines, you can efficiently harness the capabilities of CNC technology and produce high-quality components. With practice, you’ll gain confidence in your skills and might even find yourself taking on more complex projects. Enjoy the process and happy machining!