Grind machining represents a specialized category of subtractive manufacturing that utilizes abrasive particles bonded into various tool forms to achieve exceptional surface finishes and tight dimensional tolerances unattainable through conventional cutting methods. This high-precision process operates on the fundamental principle of microscale material removal, where geometrically undefined abrasive grains (typically aluminum oxide, silicon carbide, cubic boron nitride, or diamond) interact with workpiece surfaces at controlled depths ranging from 0.1 to 100 microns per pass. Modern grind machining systems incorporate rigid machine structures constructed from polymer concrete or thermally stabilized cast iron to minimize vibration-induced inaccuracies, with hydrostatic or aerostatic guideways maintaining straightness within 1 micron per 300mm of travel. Spindle technologies have advanced to support rotational speeds exceeding 60,000 RPM for small-diameter grinding wheels (below 10mm) while delivering torque outputs up to 500 Nm for heavy stock removal operations, all while maintaining rotational accuracies below 0.1 micron TIR (Total Indicator Reading) through active magnetic bearing systems or precision angular contact bearings.

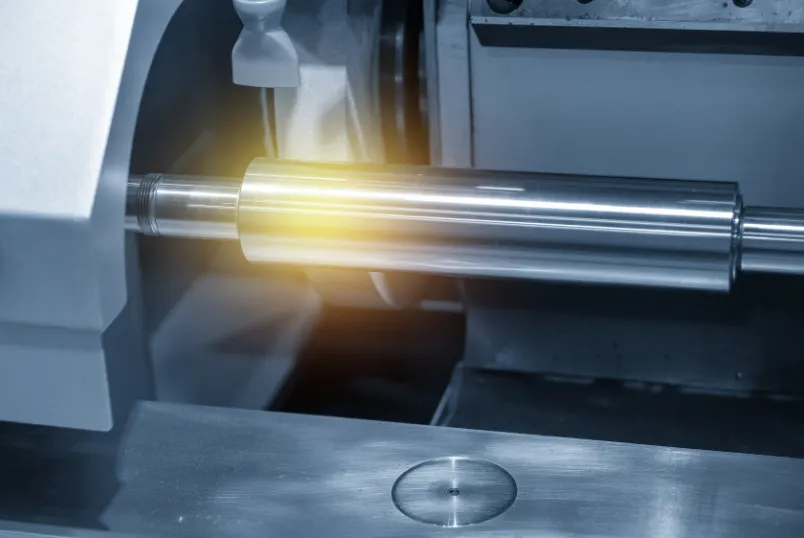

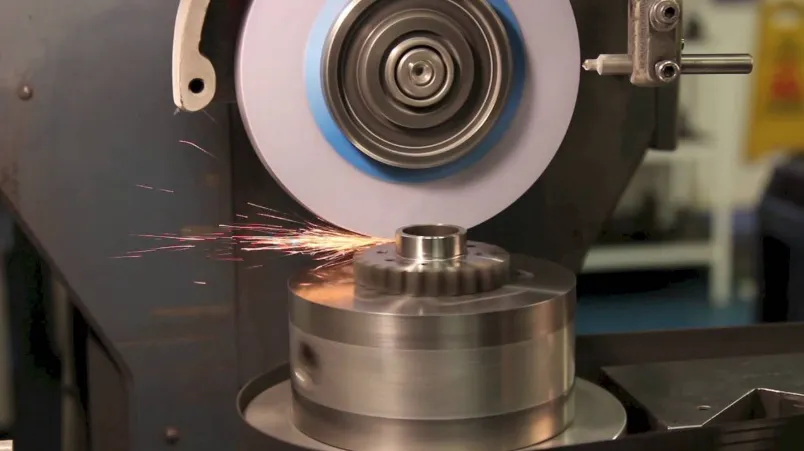

The process kinematics of grind machining involve complex interactions between multiple variables including wheel topography, workpiece material properties, and coolant delivery parameters. Conventional surface grinding operations employ reciprocating or rotary table movements with cross-feeds as fine as 0.1 micron, achieving flatness tolerances within 0.5 microns per 100mm on hardened tool steels. Cylindrical grinding machines, both external and internal configurations, synchronize workpiece rotation (typically 50-500 RPM) with wheel traverse to produce roundness accuracies below 0.25 microns and surface finishes to 0.05 micron Ra. Creep-feed grinding represents a specialized variant that combines deep cuts (up to 6mm) with slow feed rates (5-500 mm/min), generating substantial material removal rates while maintaining thermal control through high-pressure coolant delivery systems operating at 40-150 bar. Tool and cutter grinding machines employ multi-axis CNC controls (up to 9 interpolated axes) to generate and sharpen complex cutting tool geometries with flank face accuracies within 2 microns and cutting edge radii controllable down to 3 microns.

Abrasive tool technology forms the core of grind machining processes, with wheel specifications carefully engineered for specific applications. Conventional vitrified bonded aluminum oxide wheels (A or WA grades) remain standard for general-purpose steel grinding, while ceramic aluminum oxide (SG) grains offer improved performance in nickel-based superalloys due to their self-sharpening characteristics. Superabrasive wheels utilizing cubic boron nitride (CBN) or synthetic diamond abrasives have become indispensable for hard materials (above 45 HRC) and non-ferrous metals respectively, with metal, resin, or vitrified bonds tailored to optimize cutting action and wheel life. Wheel topography is precisely controlled through dressing processes using single-point diamond dressers (for form grinding applications) or rotary diamond dressers (for high-production operations), with modern CNC dressers capable of reproducing wheel profiles within 1 micron accuracy. Electroplated superabrasive wheels eliminate the need for dressing in certain applications, featuring a monolayer of abrasive particles permanently bonded to a steel core for consistent performance throughout tool life.

Coolant technology plays a critical role in grind machining, serving multiple functions including heat dissipation, lubrication, and swarf removal. Water-based synthetic coolants with extreme pressure (EP) additives dominate industrial applications, formulated to maintain pH stability between 8.5-9.5 while preventing bacterial growth that could clog coolant delivery systems. High-pressure coolant nozzles (up to 150 bar) are strategically positioned to penetrate the grinding zone’s air barrier created by wheel rotation, with flow rates reaching 200 liters per minute per 100mm of wheel width in heavy-duty applications. Filtration systems maintain coolant cleanliness to sub-10 micron particle levels using combinations of magnetic separators, centrifugal cleaners, and paper belt filters – critical for preventing workpiece surface damage and preserving machine component longevity. Minimum Quantity Lubrication (MQL) systems have gained acceptance for certain applications, delivering precisely metered amounts of oil mist (5-50 ml/hour) to the cutting zone while eliminating the need for bulk coolant handling and disposal.

Industrial applications of grind machining span critical components across multiple sectors. The automotive industry relies on precision grinding for crankshaft journals (maintaining diameter tolerances of ±1 micron), fuel injection components (with surface finishes below 0.1 micron Ra), and transmission gears (achieving profile modifications within 1 micron). Aerospace manufacturers utilize creep-feed grinding for turbine blade root forms (contour accuracy within 3 microns) and centerless grinding for engine bearing races (roundness below 0.5 micron). The medical device industry employs micro-grinding processes for implant surfaces requiring specific texture profiles between 0.5-2 micron Sa (areal roughness) and surgical cutting tools with edge radii below 5 microns. Even consumer electronics manufacturing depends on ultra-precision grinding for optical components like camera lens mounts (positional accuracy within 1 micron) and semiconductor wafer backgrinding to thicknesses below 50 microns.

Process monitoring and control systems have become integral to modern grind machining operations. Acoustic emission sensors (operating in the 50kHz-1MHz range) detect wheel-workpiece contact with micron-level sensitivity, enabling automatic wheel dressing cycles and collision avoidance. Power monitoring systems analyze spindle load variations to identify wheel dulling or workpiece material inconsistencies, triggering adaptive control responses that adjust feed rates within milliseconds. In-process gaging systems measure part dimensions during grinding cycles, with closed-loop feedback compensating for wheel wear or thermal effects to maintain size control within 0.2 microns over production runs. Machine vision systems inspect surface quality at production rates, identifying defects like burns or cracks that could compromise component performance. These monitoring technologies integrate with Industry 4.0 platforms, providing data for predictive maintenance algorithms that forecast wheel life and machine component wear before quality is affected.

Emerging technologies continue advancing grind machining capabilities. Laser-assisted grinding combines localized workpiece heating with abrasive removal, significantly reducing forces when processing difficult materials like silicon nitride or titanium aluminides. Ultrasonic vibration-assisted grinding superimposes high-frequency (20-40 kHz) oscillations onto conventional grinding motions, improving surface integrity in brittle materials by transitioning material removal mechanisms from brittle fracture to ductile flow. Hybrid additive-grinding processes build near-net-shape components through directed energy deposition before finish grinding critical features, reducing material waste and lead times. Artificial intelligence applications analyze vast datasets from sensors and historical operations to optimize grinding parameters in real-time, automatically compensating for wheel wear and material variations while maintaining consistent output quality. These innovations ensure grind machining remains at the forefront of precision manufacturing technologies, capable of meeting increasingly stringent requirements for part performance and production efficiency.

Maintenance protocols for grind machining equipment emphasize preserving micron-level accuracy. Daily inspections include checking hydrostatic bearing pressures (typically 20-50 bar), lubricant levels in way lubrication systems (ISO VG 22 or 32), and coolant concentration (maintained at 3-5% for water-soluble types). Weekly preventive maintenance involves verifying spindle vibration levels (below 0.8 mm/s RMS), recalibrating in-process gaging systems, and cleaning way covers to prevent abrasive particle accumulation. Quarterly overhauls may include hydrostatic bearing clearance adjustments (maintaining 10-15 micron gaps), replacement of rotary union seals in coolant delivery systems, and full geometric accuracy verification using laser interferometry to confirm axis straightness (<1 micron/300mm) and squareness (<2 microns/300mm). Proper maintenance combined with controlled operating environments (temperature stability within ±0.5°C, humidity below 60% RH) enables high-precision grinders to maintain specified accuracies for decades of production service.

The economic impact of grind machining reflects its critical role in value-added manufacturing. While accounting for only 5-10% of total part production costs in many components, grinding often determines the functional performance and service life of precision parts. Advances in wheel technology and process optimization have reduced grinding costs by 30-40% over the past two decades through increased material removal rates (up to 500 mm³/mm/s in certain applications) and extended wheel life. Environmental improvements like dry grinding techniques and advanced coolant filtration systems have decreased waste generation by 60-80% while maintaining part quality. The global market for precision grinding services exceeds $25 billion annually, driven by growing demand from industries requiring ever-tighter tolerances and superior surface integrity in critical components.

Future developments in grind machining focus on increasing process intelligence and sustainability. Self-dressing wheel technologies that maintain optimal abrasive sharpness throughout tool life are under development, potentially eliminating scheduled dressing interruptions. Nanofluid coolants containing suspended nanoparticles promise enhanced heat transfer capabilities that could enable higher removal rates without thermal damage. Digital twin technology creates virtual grinding process models that predict outcomes before physical machining begins, reducing setup times and material waste. Standardization efforts aim to create universal data models for grinding processes that can be shared across machine platforms and locations. These innovations will continue to elevate grind machining from a traditional finishing operation to a comprehensive precision manufacturing solution capable of meeting evolving industry demands for higher quality, increased efficiency, and greater process transparency.