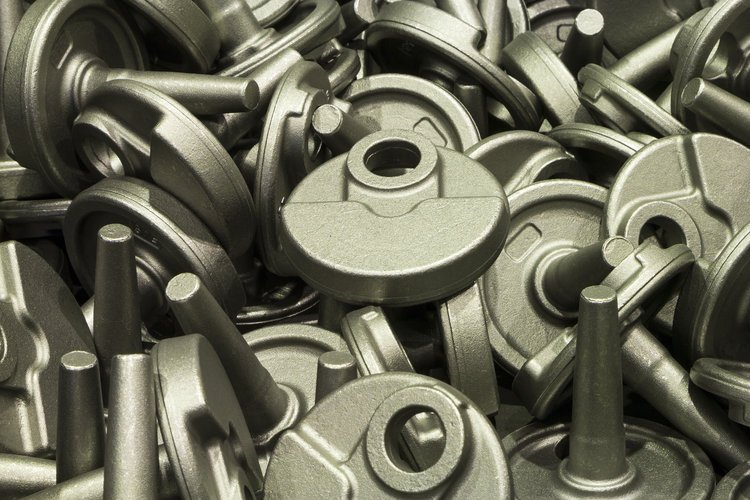

Forging parts manufacturers specialize in shaping metal through compressive forces to produce high-strength components for critical applications. These industrial facilities operate various forging techniques to create parts with superior mechanical properties compared to cast or machined alternatives.

Forging Processes and Equipment

Forging Processes and Equipment

Modern forging manufacturers utilize several metal-forming methods:

- Closed-Die Forging (Impression Die Forging)

- Uses matched dies to shape heated metal blanks

- Produces near-net-shape components with tight tolerances (±0.015″)

- Typical capacities: 5-20,000 ton presses

- Common applications: automotive crankshafts, connecting rods

- Open-Die Forging

- Processes metal between flat dies with repeated blows

- Creates large, simple shapes (shafts, rings, cylinders)

- Equipment includes hydraulic presses (up to 60,000 tons) and hammer forges

- Roll Ring Forging

- Forms seamless rings by compressing and rolling preformed doughnuts

- Produces diameters from 6″ to 30+ feet

- Applications: bearing races, flanges, turbine rings

- Precision Forging

- Advanced closed-die process achieving near-final contours

- Minimizes machining requirements

- Tolerances reach ±0.005″ for critical aerospace components

Material Capabilities

Forging manufacturers work with various metal alloys:

- Carbon and Alloy Steels (1045, 4140, 4340)

- Stainless Steels (304, 316, 17-4PH)

- Aluminum Alloys (2014, 6061, 7075)

- Titanium Alloys (Grade 2, Grade 5)

- Nickel-Based Superalloys (Inconel 718, Waspaloy)

Material selection depends on application requirements for strength, corrosion resistance, and temperature tolerance.

Production Workflow

The manufacturing sequence typically involves:

- Billet Preparation

- Saw cutting or shearing to required weights

- Induction/heating to 1,100-2,300°F depending on material

- Forming Operations

- Pre-forming (blocking, edging)

- Finish forging in precision dies

- Flash removal (trimming)

- Post-Forging Processes

- Heat treatment (normalizing, quenching/tempering)

- Shot blasting for surface cleaning

- Non-destructive testing (UT, MT, PT)

- Machining to final dimensions

Quality Assurance Systems

Reputable forging manufacturers implement rigorous quality controls:

- Material Certification (MTRs to ASTM/AMS standards)

- Dimensional Inspection (CMM, optical comparators)

- Mechanical Testing (tensile, impact, hardness)

- Microstructure Analysis (grain flow verification)

- NDT Methods (ultrasonic, magnetic particle, dye penetrant)

Industry Applications

Forged components serve critical functions across sectors:

Automotive

- Engine parts (crankshafts, connecting rods)

- Transmission components (gears, shafts)

- Chassis elements (knuckles, control arms)

Aerospace

- Landing gear components

- Turbine engine disks

- Structural airframe parts

Energy

- Oilfield tools (valve bodies, drill bits)

- Power generation turbine shafts

- Wind turbine spindle forgings

Industrial Equipment

- Heavy machinery components

- Mining equipment parts

- Hydraulic cylinder rods

Technical Advantages

Forged parts offer distinct benefits:

- Superior Strength – Continuous grain flow increases fatigue resistance

- Material Efficiency – Near-net-shape production minimizes waste

- Reliability – Fewer defects compared to casting

- Cost Effectiveness – Reduced machining requirements for many applications

Manufacturing Capability Trends

Modern forging manufacturers are adopting:

- Automated Forging Lines with robotic handling

- Simulation Software for process optimization

- Energy-Efficient Heating systems

- Industry 4.0 Integration with process monitoring

These industrial facilities range from small specialty shops to large-scale operations producing millions of parts annually, all maintaining the fundamental advantages of forged metal components – structural integrity, reliability, and performance in demanding applications.