Automation technologies have become indispensable in food processing and medical manufacturing, addressing critical requirements for hygiene, precision, and traceability. These sectors represent 38% of total industrial automation expenditures globally (IFR 2023 statistics), with distinct technical implementations tailored to their unique operational constraints.

1. Raw Material Handling Systems

- Optical sorters process 15 tons/hour of produce with 99.5% defect detection

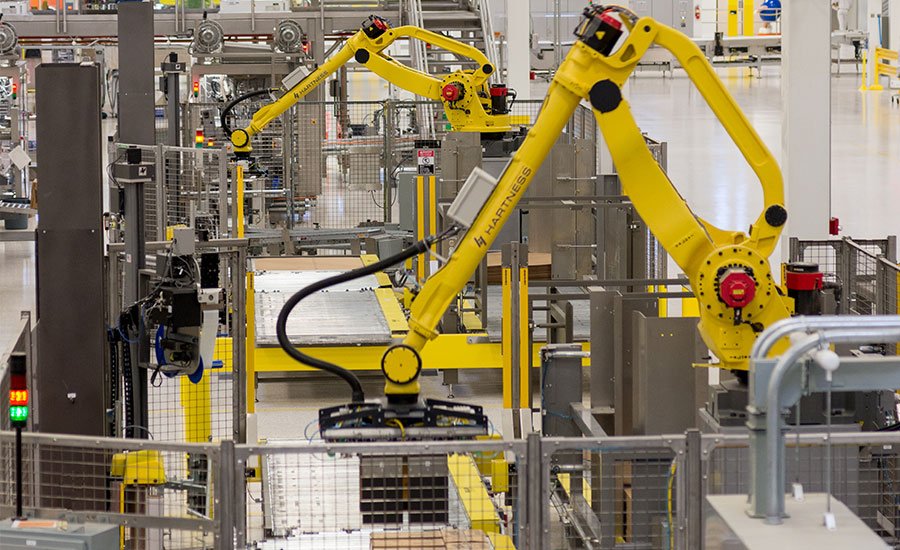

- Robotic palletizers handle 30 cases/minute at 50kg payload capacity

- X-ray inspection systems detect contaminants ≥0.8mm in packaged goods

2. Processing Equipment

- Automated deboning machines achieve 98% meat recovery rates

- High-pressure pasteurization systems operate at 6,000 bar (600MPa)

- Continuous fryers maintain oil temperature within ±1°C at 180°C setpoints

3. Packaging Solutions

- Aseptic filling machines process 40,000 containers/hour

- Modified atmosphere packaging systems achieve 0.5% O₂ residual levels

- Checkweighers verify mass within ±0.1g accuracy at 400ppm rates

4. Sanitation Technologies

- Clean-in-Place (CIP) systems reduce downtime by 70% versus manual cleaning

- Electropolished stainless steel surfaces (Ra ≤0.8μm) prevent bacterial adhesion

- UV-C tunnel disinfectors provide 5-log pathogen reduction

Medical Device Automation

1. Sterile Manufacturing

- Isolator environments maintain ISO Class 5 conditions

- Delta robots assemble syringes at 300 units/minute

- Vision systems inspect 0.3mm catheter features with 2μm resolution

2. Pharmaceutical Production

- High-speed tablet presses output 1,000,000 doses/8-hour shift

- Automated vial filling achieves ±0.5% volume accuracy

- Lyophilization systems control shelf temperatures to ±0.5°C

3. Diagnostic Equipment

- Automated analyzers process 1,200 tests/hour

- Microfluidic handling systems manipulate 50nL droplets

- AI-assisted imaging systems detect 20μm pathological features

Cross-Sector Automation Technologies

1. Robotics Implementation

- SCARA robots achieve 0.02mm repeatability in assembly tasks

- Collaborative robots (cobots) operate at ≤0.5m/s speeds in shared spaces

- Mobile robots transport materials in 100,000+ Class cleanrooms

2. Process Control Systems

- PLC networks monitor 500+ parameters in real-time

- PAT (Process Analytical Technology) ensures QbD compliance

- Blockchain systems track 200+ data points per product unit

3. Materials Compliance

- FDA 21 CFR compliant lubricants for incidental food contact

- USP Class VI certified components for medical applications

- EHEDG-certified equipment designs for hygienic processing

Regulatory Framework Integration

Food Sector Requirements

- HACCP-controlled critical control points

- 3-A Sanitary Standards for dairy equipment

- FSMA-mandated environmental monitoring

Medical Sector Mandates

- FDA 21 CFR Part 11 electronic records compliance

- ISO 13485 quality management systems

- EU MDR Unique Device Identification (UDI) implementation

Emerging Technological Developments

- AI-powered quality prediction systems reducing waste by 15-30%

- Digital twin simulations cutting validation time by 40%

- Self-disinfecting surfaces with 99.99% antimicrobial efficacy

- Quantum dot tracing for supply chain authentication

The convergence of these automation technologies continues to redefine production paradigms in both sectors, with particular emphasis on data integrity, flexible manufacturing, and sustainable operations. Implementation challenges persist in balancing regulatory compliance with operational efficiency, driving ongoing innovation in modular system designs and adaptive control architectures. Current research focuses on bio-compatible automation solutions and cognitive systems capable of autonomous quality decision-making, promising further transformation of these critical industries.