An EDM (Electrical Discharge Machining) machine represents a specialized non-traditional manufacturing system that removes material through controlled electrical discharges between an electrode and a conductive workpiece submerged in dielectric fluid. These computer-controlled systems utilize precisely regulated spark erosion to cut complex geometries in hardened metals and exotic alloys that prove challenging for conventional machining methods, achieving tolerances within ±0.005mm (±0.0002 inches) and surface finishes as fine as 0.1μm Ra in advanced configurations. Modern EDM machines consist of several critical subsystems including a power supply generating controlled pulses at voltages ranging from 50-300V with current capabilities up to 500A, a servo-controlled positioning system maintaining gap distances of 10-50μm between electrode and workpiece, and a dielectric circulation system that filters and conditions deionized water or hydrocarbon-based fluids to maintain optimal sparking conditions.

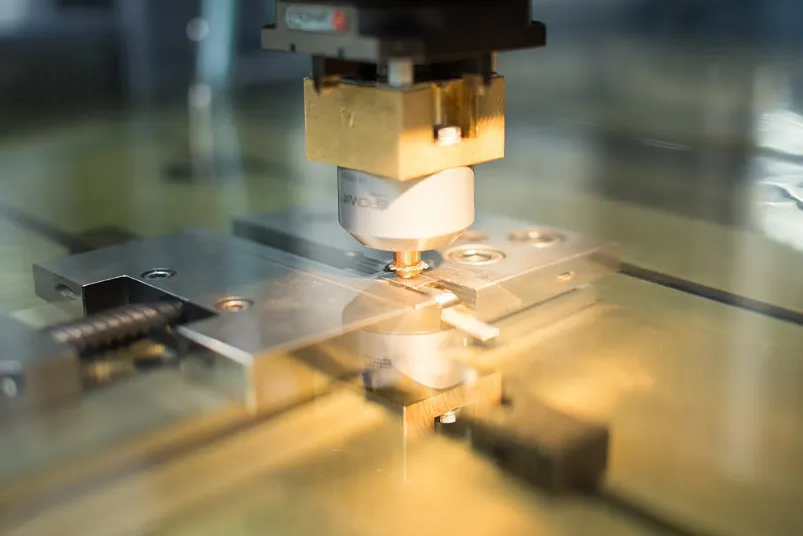

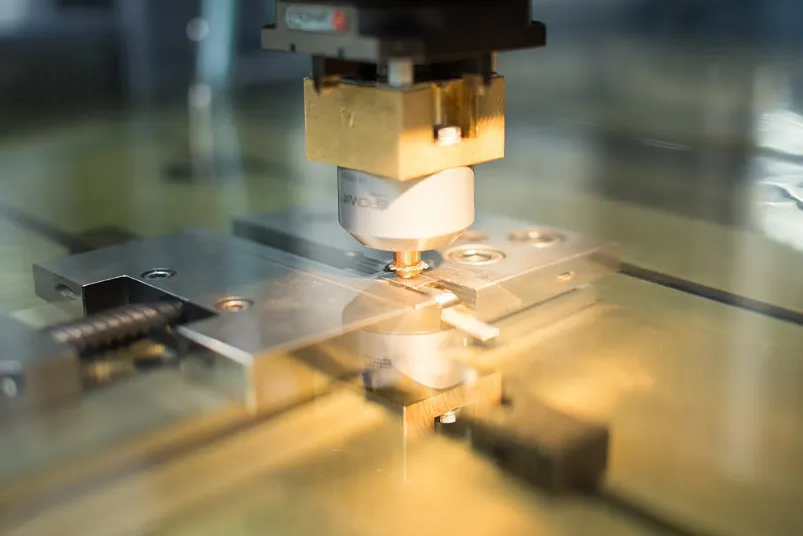

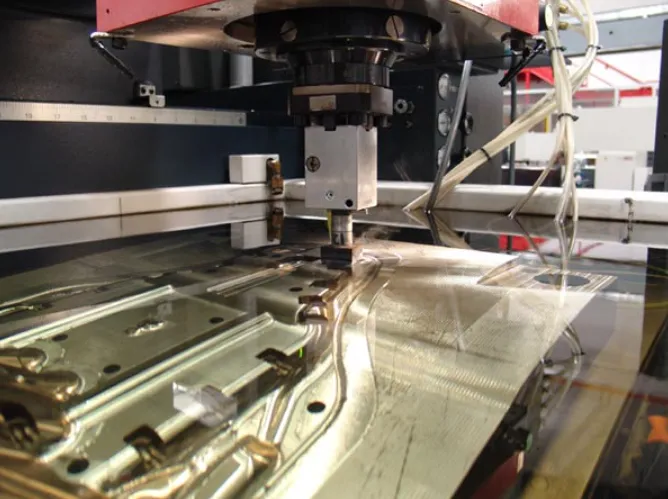

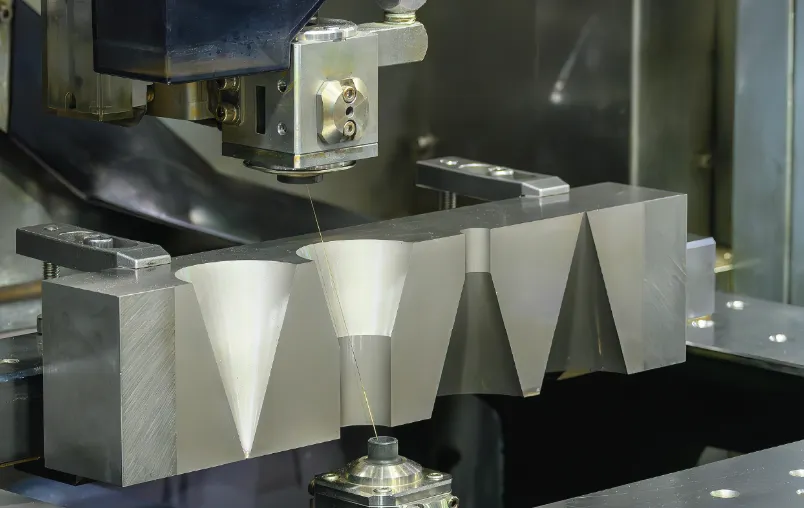

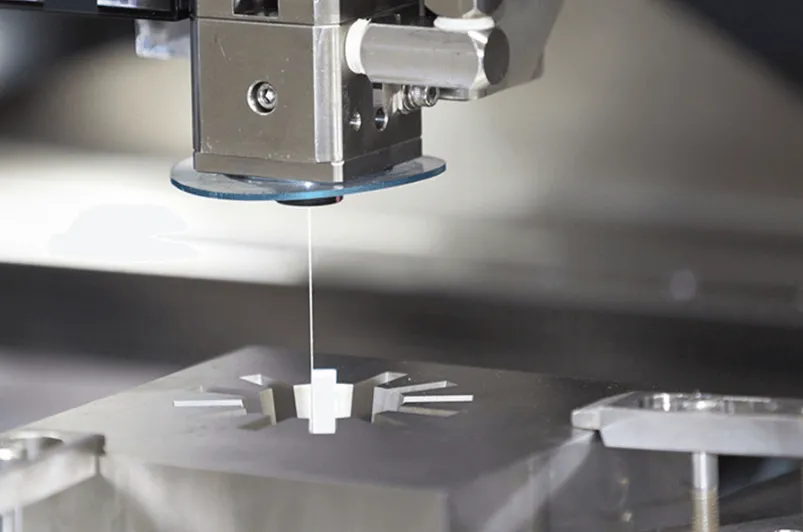

The two primary EDM variants – sinker EDM (also called ram EDM) and wire EDM – employ distinct methodologies for material removal while sharing fundamental spark erosion principles. Sinker EDM machines utilize shaped electrodes (typically graphite or copper) that replicate inverse geometries into workpieces through thousands of sparks per second, with advanced machines incorporating multi-axis CNC controls (up to 5 axes) for complex cavity machining in hardened tool steels. These systems precisely control spark duration (as short as 0.1μs for fine finishing) and off-time intervals to optimize material removal rates (typically 100-500mm³/min for roughing) while minimizing electrode wear (as low as 0.1% for copper electrodes in finish passes). Wire EDM machines employ continuously fed brass or coated wires (0.02-0.3mm diameter) as electrodes to cut intricate profiles through conductive materials, with precision guide systems maintaining wire position within 1μm and CNC controls coordinating X-Y-U-V axis movements to produce tapers up to 30° or intricate shapes with sharp inside corners.

The two primary EDM variants – sinker EDM (also called ram EDM) and wire EDM – employ distinct methodologies for material removal while sharing fundamental spark erosion principles. Sinker EDM machines utilize shaped electrodes (typically graphite or copper) that replicate inverse geometries into workpieces through thousands of sparks per second, with advanced machines incorporating multi-axis CNC controls (up to 5 axes) for complex cavity machining in hardened tool steels. These systems precisely control spark duration (as short as 0.1μs for fine finishing) and off-time intervals to optimize material removal rates (typically 100-500mm³/min for roughing) while minimizing electrode wear (as low as 0.1% for copper electrodes in finish passes). Wire EDM machines employ continuously fed brass or coated wires (0.02-0.3mm diameter) as electrodes to cut intricate profiles through conductive materials, with precision guide systems maintaining wire position within 1μm and CNC controls coordinating X-Y-U-V axis movements to produce tapers up to 30° or intricate shapes with sharp inside corners.

The dielectric fluid system plays a critical role in EDM operations, serving multiple functions including spark channel formation, debris removal, and cooling. Wire EDM machines primarily use deionized water with resistivity carefully controlled between 5-50 kΩ·cm through continuous ion exchange filtration, while sinker EDM often employs hydrocarbon-based dielectric oils with flash points around 110-140°C. High-pressure flushing systems (up to 15 bar) direct dielectric flow through specially designed nozzles to efficiently remove eroded particles from the cutting zone, preventing secondary sparking that could compromise surface finish. Advanced filtration systems maintain dielectric cleanliness to sub-5μm particle levels using combinations of paper filters, centrifugal separators, and electrostatic precipitators – critical for achieving consistent machining performance and extended component life. Temperature control units regulate dielectric fluid within ±0.5°C of setpoint to minimize thermal distortion during precision operations.

Control systems on modern EDM machines incorporate sophisticated adaptive technologies that monitor and optimize the sparking process in real-time. Gap voltage sensing (sampled at MHz frequencies) detects abnormal discharge conditions, with the CNC automatically adjusting servo feed rates to maintain optimal spark gap distance. Advanced power supplies utilize transistor-controlled pulse generators that shape individual sparks with precision, allowing independent control of current rise time, duration, and interval to balance removal rate against surface finish requirements. Some machines incorporate machine learning algorithms that analyze historical performance data to automatically optimize parameters for specific material-electrode combinations, reducing setup time by 30-50%. The human-machine interface typically features touchscreen controls displaying real-time spark condition analysis, electrode wear compensation data, and 3D machining simulations, with some systems offering augmented reality overlays for setup verification.

EDM machines handle an extensive range of conductive materials that challenge conventional cutting tools. Hardened tool steels (up to 65 HRC) represent common applications, with EDM providing the only practical method for machining intricate features after heat treatment. Tungsten carbide machining utilizes reverse-polarity EDM with specialized graphite electrodes to achieve precise geometries without inducing microcracks. Aerospace applications frequently employ EDM for nickel-based superalloys like Inconel, where the process avoids the work hardening issues encountered with mechanical cutting. Other specialty materials effectively processed by EDM include titanium alloys, polycrystalline diamond compacts, and metal matrix composites. The technology also machines delicate features in thin materials (down to 0.1mm thickness) without distortion, as the process exerts negligible mechanical force on the workpiece.

Industrial applications of EDM technology span critical manufacturing sectors requiring precision in hard materials. The tool and die industry relies heavily on sinker EDM for producing injection molds with complex cores and cavities, often achieving draft angles and textured surfaces in a single operation. Wire EDM proves indispensable for manufacturing precision gears and splines in hardened steels, maintaining tooth profile accuracies within 0.005mm after heat treatment. The medical device industry utilizes micro-EDM (using electrodes as small as 0.03mm diameter) to create intricate features in surgical instruments and implant components. Aerospace manufacturers employ EDM for turbine blade cooling holes and fuel system components requiring precise geometries in heat-resistant alloys. Even the electronics industry uses EDM for producing precision dies for connector pins and semiconductor lead frames, where conventional machining would compromise delicate features.

Technological advancements continue expanding EDM capabilities through several key innovations. Dry EDM techniques using gaseous dielectrics reduce environmental impact while enabling machining of materials sensitive to liquid dielectric contamination. High-speed EDM drilling machines achieve penetration rates exceeding 10mm/min in tough materials using rotating tubular electrodes and enhanced dielectric flushing. Hybrid EDM-milling machines combine traditional EDM with mechanical rotation of form electrodes, enabling complex 3D geometries without dedicated electrode fabrication. Additive EDM processes build up surface features through controlled material deposition from sacrificial electrodes. Monitoring systems have advanced to include real-time spark location analysis using high-speed cameras, allowing detection and compensation of abnormal discharge conditions before they affect part quality.

Operational parameters in EDM require careful optimization based on material, desired finish, and accuracy requirements. Roughing operations in steel might use high current (50-100A) with long pulse durations (100-200μs) to maximize removal rates, while finishing passes employ currents below 5A with pulse durations under 1μs to achieve mirror-like surfaces. Electrode wear compensation algorithms automatically adjust the tool path based on measured wear rates, maintaining dimensional accuracy through multiple roughing and finishing passes. Wire EDM machines carefully control wire tension (typically 5-15N for 0.25mm wire) and feed rates (5-15mm/s) to minimize wire breakage while optimizing cutting speed. Advanced machines store hundreds of material-specific parameter sets and automatically recall appropriate settings when workpiece materials are identified through barcode scanning or manual input.

Maintenance protocols for EDM machines focus on preserving their exceptional precision capabilities. Daily maintenance includes checking dielectric fluid levels and resistivity, cleaning work tanks, and inspecting filters for clogging. Weekly tasks involve verifying guide and way lubrication (using way oil with ISO VG 32 or 68), checking wire alignment on wire EDMs, and calibrating gap sensing systems. Monthly preventive maintenance includes cleaning dielectric circulation pumps, inspecting power cables and contacts for erosion, and verifying axis positioning accuracy using laser interferometry or precision gauge blocks. Annual overhauls may require replacement of dielectric filters, servo motor brushes, and guide components, along with comprehensive electrical system testing to ensure stable spark generation. Proper maintenance combined with controlled operating environments (temperature stability within ±1°C, humidity below 70% RH) enables EDM machines to maintain specified accuracies for decades of production service.

Future developments in EDM technology focus on increasing process efficiency and integration with digital manufacturing systems. Research into plasma-channel controlled EDM aims to improve energy utilization efficiency from current 30-40% levels to above 60%. Intelligent adaptive control systems using artificial intelligence promise to automatically optimize parameters throughout the machining cycle based on real-time spark condition analysis. The integration of EDM with additive manufacturing systems allows for hybrid processes that build and finish complex components in single setups. Standardization efforts aim to create universal data models for EDM processes that can be shared across machine platforms and locations. As Industry 4.0 initiatives progress, EDM machines are evolving into networked manufacturing nodes that not only perform machining but also collect process data for predictive maintenance and quality assurance systems – transforming what was once considered a specialized process into an intelligent manufacturing solution capable of meeting increasingly stringent industry requirements.