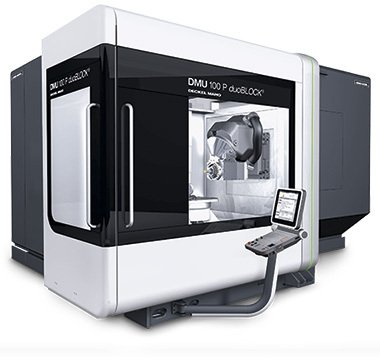

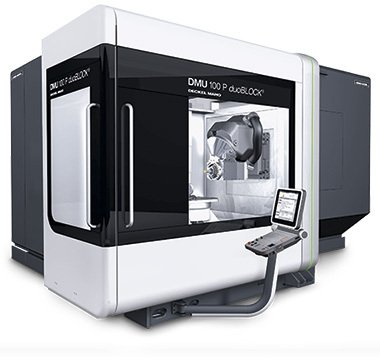

The DMU100P duoBLOCK represents the pinnacle of German machining technology, offering a massive 1,000 × 1,000 × 800mm work area with exceptional 0.005mm/m positioning accuracy. The revolutionary duoBLOCK construction provides unmatched thermal stability, maintaining less than 5μm thermal drift over 8 hours of continuous operation. With its 18,000rpm, 48kW spindle delivering 350Nm continuous torque, this machine handles everything from aluminum to high-temperature alloys with ease.

Key Specifications

- Work Envelope: 1,000 × 1,000 × 800mm (39.4″ cube)

- Spindle: 18,000rpm (48kW/350Nm) with HSK-A100 interface

- Rapid Traverse: 50m/min (1,969 ipm) all axes

- Positioning Accuracy: 0.005mm/m (0.0002″/ft)

- Repeatability: ±0.003mm (0.00012″)

- Control System: Heidenhain TNC640 with 19″ touchscreen

5-Axis Performance

- Rotary Table: Ø800mm (31.5″) with 500kg (1,102 lbs) capacity

- Tilting Range: ±110° (A-axis) with 0.0001° resolution

- Simultaneous 5-Axis: Full support for complex freeform surfaces

- Table Speed: 30rpm continuous, 50rpm positioning

- Direct Measuring Systems: Absolute encoders on all axes

duoBLOCK Technology Advantages

- Thermal Symmetry: Maintains <5μm thermal drift over 8 hours

- Vibration Damping: 3x better than conventional designs

- Structural Rigidity: 25% higher stiffness compared to competitors

- Accessibility: 3-side machine access for easy loading

- Thermal Management: Active cooling of spindle, axes, and control cabinet

Detailed Technical Data

| Parameter | Specification |

|---|---|

| X/Y/Z Travel | 1,000/1,000/800mm (39.4″) |

| Rapid Traverse Rate | 50m/min (1,969 ipm) |

| Cutting Feed Rate | 1-30,000mm/min |

| Tool Capacity | 60+1 tools (optional 120+1) |

| Tool Change Time | 3.5 sec (chip-to-chip) |

| Spindle Power (cont./40%) | 48kW/60kW |

| Spindle Torque (cont./40%) | 350Nm/420Nm |

| Table Diameter | Ø800mm (31.5″) |

| Machine Weight | 18,000kg (39,683 lbs) |

| Power Requirement | 75kVA (3-phase) |

| Air Consumption | 250L/min @ 6bar |

Premium Features

- Cooling Systems: Active cooling for spindle, axes, and control cabinet

- Process Monitoring: Integrated vibration and load sensors

- Automation Ready: Full compatibility with robotic systems

- High-Pressure Coolant: 80bar (1,160 psi) through-spindle option

- Tool Management: RFID chip integration available

- Safety Systems: Laser-protected work area with emergency stops

Target Industries

- Die/Mold: Complex cavities, electrodes, forming tools

- Energy Sector: Turbine housings, compressor vanes, manifolds

- Precision Engineering: Optical components, scientific instruments

- Aerospace: Structural components, engine parts, landing gear

- Automotive: Prototypes, transmission cases, suspension components

Installation Requirements

- Floor Space: 4,500 × 5,000mm (177″ × 197″) including service area

- Foundation: 500mm (20″) reinforced concrete minimum

- Power: 400VAC ±10%, 50/60Hz, 3-phase

- Compressed Air: 6bar (87 psi) clean, dry air

- Ambient Temperature: 18-22°C (64-72°F) optimal

- Installation Time: 3-5 days with factory support

Maintenance Program

- Daily Checks: Way covers, lubrication levels, coolant condition

- Weekly Maintenance: Air filter inspection, chip removal

- Monthly Service: Guideway lubrication, ball screw inspection

- Annual Overhaul: Complete system diagnostics and recalibration

- Spindle Maintenance: 30,000-hour expected bearing life