Woodworking has come a long way from the days of hand tools and manual labor. Today, CNC wood cutting machines are at the forefront of the industry, offering unparalleled precision, efficiency, and versatility. Whether you’re crafting intricate furniture, creating custom cabinetry, or producing decorative art pieces, these machines have transformed the way woodworkers approach their craft. This article explores the world of CNC wood cutting machines, their features, applications, and how they are shaping the future of woodworking.

What is a CNC Wood Cutting Machine?

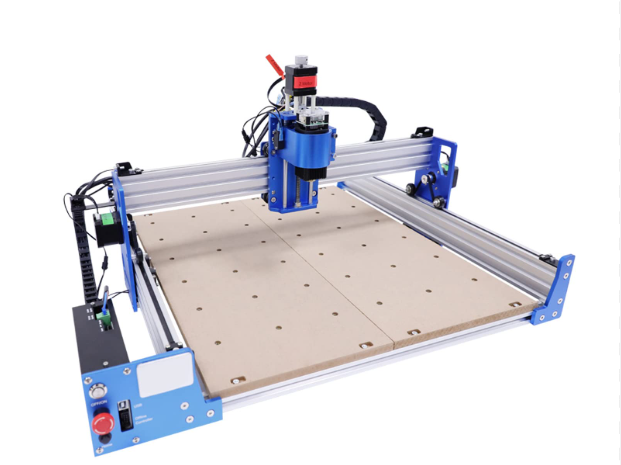

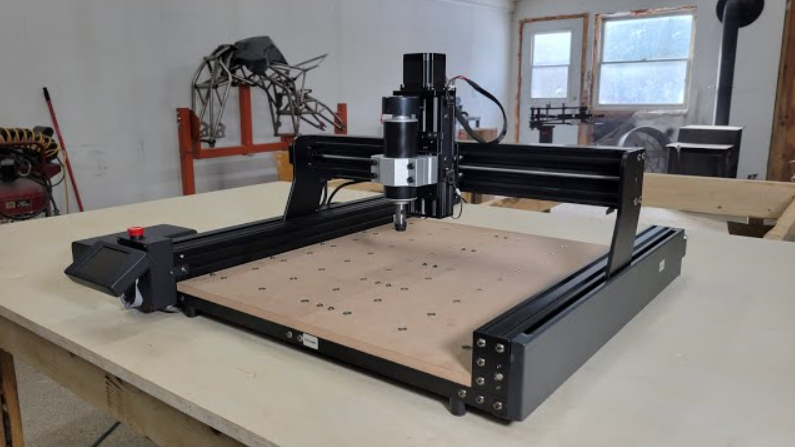

A CNC wood cutting machine is a computer-controlled device designed to cut, carve, and shape wood with high precision. These machines use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to translate digital designs into physical objects. By automating the cutting process, CNC wood cutting machines eliminate human error and significantly reduce production time.

Why CNC Wood Cutting Machines Matter

- Precision: Achieve intricate designs with tolerances as tight as ±0.005 inches (0.127 mm).

- Efficiency: Complete complex projects in a fraction of the time compared to manual methods.

- Versatility: Work with a wide range of wood types, from softwoods like pine to hardwoods like oak and mahogany.

- Repeatability: Produce identical parts with consistent quality, ideal for batch production.

Types of CNC Wood Cutting Machines

Types of CNC Wood Cutting Machines

There are several types of CNC wood cutting machines, each suited to specific applications:

1. CNC Routers

CNC routers are the most common type of wood cutting machines. They use rotating cutting tools to carve and shape wood.

- Applications: Furniture making, sign making, and cabinetry.

- Advantages: High precision, large work area, and ability to handle detailed designs.

- Example: The Shapeoko 4 is a popular CNC router for hobbyists and small businesses.

2. CNC Laser Cutters

CNC laser cutters use a high-powered laser beam to cut and engrave wood.

- Applications: Decorative art, intricate patterns, and custom engravings.

- Advantages: Clean cuts, minimal material waste, and ability to create fine details.

- Example: The Glowforge Pro is a well-known CNC laser cutter for creative projects.

3. CNC Plasma Cutters

While primarily used for metal, CNC plasma cutters can also cut wood, especially for large-scale projects.

- Applications: Large signs, structural components, and industrial designs.

- Advantages: Fast cutting speed and ability to handle thick materials.

- Example: The Hypertherm Powermax series is a reliable choice for industrial applications.

Applications of CNC Wood Cutting Machines

CNC wood cutting machines are used across a wide range of industries and applications:

1. Furniture Making

CNC machines are ideal for creating custom furniture with intricate designs and precise joinery.

- Example: A furniture maker used a CNC router to produce a set of custom dining chairs with intricate carvings, reducing production time by 50%.

2. Cabinetry

CNC machines streamline the production of cabinets, ensuring precise cuts and consistent quality.

- Example: A cabinetry shop used a CNC router to produce 50 identical cabinet doors in a single day, a task that would have taken weeks manually.

3. Sign Making

CNC machines are widely used in the sign-making industry to create detailed and durable signs.

- Example: A sign-making company used a CNC laser cutter to produce a series of custom wooden signs for a local business, achieving intricate details and a professional finish.

4. Decorative Art

CNC machines enable artists to create complex and unique designs that would be difficult to achieve by hand.

- Example: An artist used a CNC router to create a large wooden mural with intricate patterns, showcasing the machine’s ability to handle detailed work.

Benefits of CNC Wood Cutting Machines

1. Precision and Accuracy

CNC machines can achieve extremely tight tolerances, ensuring that every cut is precise and accurate.

2. Increased Efficiency

CNC machines can run 24/7 with minimal supervision, significantly speeding up production.

3. Cost-Effective

While the initial investment can be high, the long-term savings in labor and material waste often justify the cost.

4. Versatility

CNC machines can work with a wide range of wood types and thicknesses, making them suitable for various projects.

Choosing the Right CNC Wood Cutting Machine

When selecting a CNC wood cutting machine, consider the following factors:

1. Work Area Size

Choose a machine with a work area that matches your project requirements.

2. Material Compatibility

Ensure the machine can handle the types of wood you plan to work with.

3. Software Compatibility

Check if the machine is compatible with the CAD/CAM software you plan to use.

4. Budget

CNC wood cutting machines range from a few hundred to several thousand dollars. Determine your budget and choose a machine that offers the best value for your needs.

Future Trends in CNC Wood Cutting Machines

The CNC wood cutting industry is evolving with advancements in technology. Key trends include:

1. Smart Features

Integration of IoT and AI for real-time monitoring and optimization.

2. Hybrid Machines

Combining CNC machining with 3D printing for greater versatility.

3. Enhanced Materials

Development of machines capable of handling harder materials like MDF and plywood.

Conclusion

CNC wood cutting machines have revolutionized the woodworking industry, offering precision, efficiency, and versatility that were previously unimaginable. Whether you’re a hobbyist, a small business owner, or an industrial manufacturer, these machines can help you achieve professional-quality results in less time and with greater consistency.

If you’re considering investing in a CNC wood cutting machine, take the time to evaluate your needs and choose a machine that aligns with your goals. With the right tool, you can unlock new possibilities and take your woodworking projects to the next level.