The CNC (Computer Numerical Control) router is a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and versatility. This article explores the technical aspects, applications, and advantages of CNC routers, drawing on data from reputable sources to provide a comprehensive and professional overview.

Technical Specifications

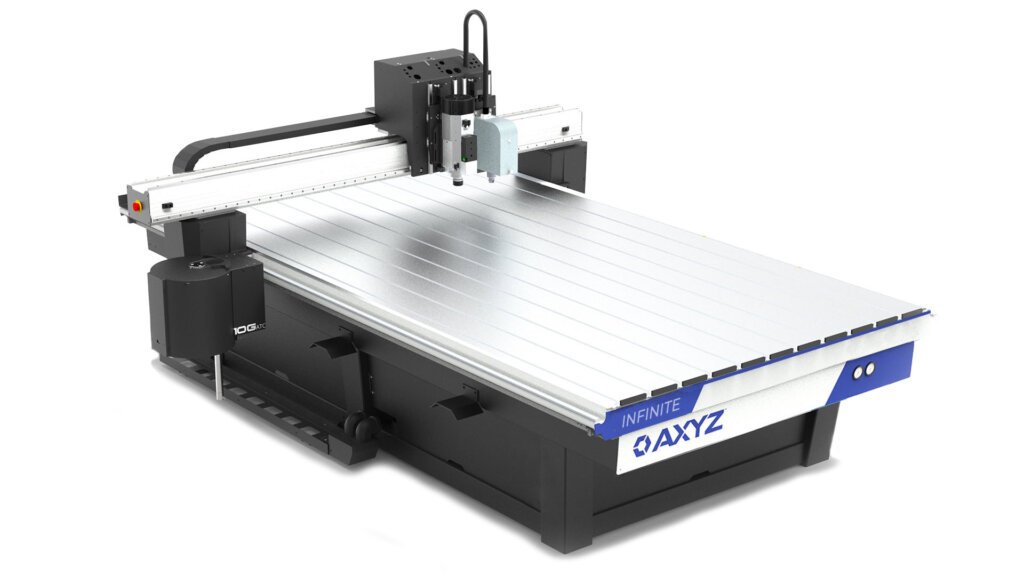

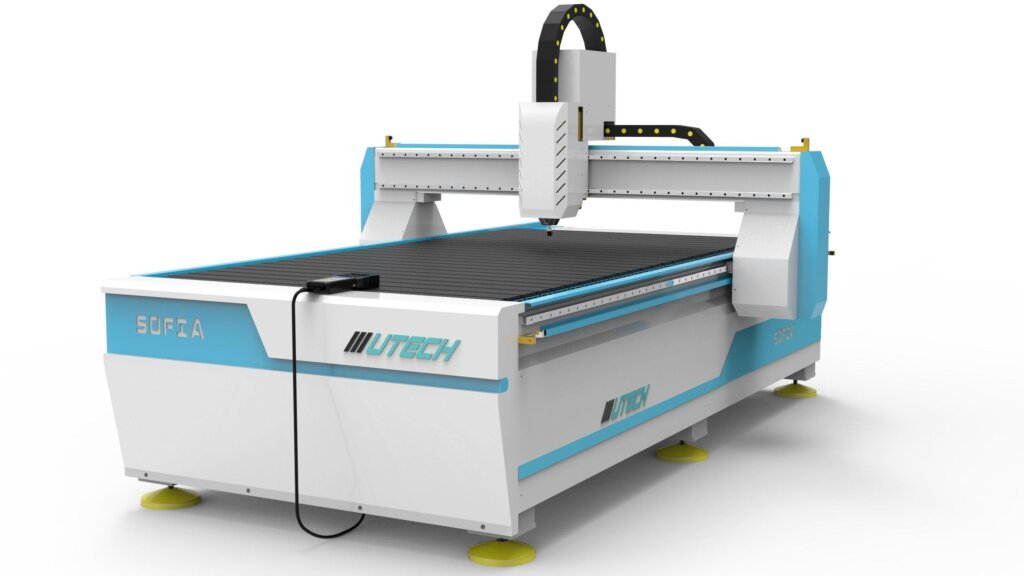

CNC routers are automated cutting machines that use computer-controlled movements to carve, cut, and shape materials with high precision. They are equipped with a spindle that rotates at high speeds, typically ranging from 8,000 to 24,000 RPM, allowing for efficient material removal. The working area of a CNC router can vary significantly, from small desktop models (e.g., 300mm x 300mm) to large industrial machines (e.g., 2,500mm x 1,250mm).

According to a study published in the International Journal of Advanced Manufacturing Technology, CNC routers achieve a positional accuracy of ±0.01mm, making them ideal for intricate designs and high-tolerance applications. The machines are typically constructed from aluminum or steel frames, ensuring stability and durability during operation. Advanced models may also feature multi-axis capabilities (e.g., 3-axis, 4-axis, or 5-axis), enabling complex geometries and undercuts.

Applications

CNC routers are widely used across various industries due to their versatility and precision. In the woodworking industry, they are employed for cutting, carving, and engraving tasks. A report from Woodworking Network highlights how CNC routers have revolutionized furniture manufacturing, enabling the production of intricate designs with minimal waste.

In the signage industry, CNC routers are used to create detailed lettering and logos from materials such as acrylic, PVC, and aluminum. A case study published in Signs of the Times demonstrates how a signage company increased production efficiency by 30% after adopting CNC routing technology.

CNC routers are also essential in the aerospace and automotive industries, where they are used to machine lightweight materials such as carbon fiber and aluminum composites. According to a study in the Journal of Materials Processing Technology, CNC routers play a critical role in producing high-strength, lightweight components for aircraft and vehicles.

Advantages

One of the primary advantages of CNC routers is their precision. The ability to follow digital designs with high accuracy ensures consistent quality across multiple production runs. A study in the Journal of Manufacturing Systems found that CNC routers reduce material waste by up to 20% compared to traditional machining methods, making them a cost-effective solution for manufacturers.

Another significant advantage is their versatility. CNC routers can process a wide range of materials, including wood, plastic, metal, and composites. This flexibility allows manufacturers to use a single machine for multiple applications, reducing the need for specialized equipment.

CNC routers also offer significant time savings. Automated tool changes and high-speed spindles enable rapid production cycles, reducing lead times and increasing throughput. A report from Modern Machine Shop highlights how a custom furniture manufacturer reduced production time by 40% after integrating CNC routers into their workflow.

Conclusion

CNC routers are a vital tool in modern manufacturing, offering precision, versatility, and efficiency. Their applications span multiple industries, from woodworking and signage to aerospace and automotive manufacturing. With their ability to reduce material waste, shorten production cycles, and handle complex designs, CNC routers are an indispensable asset for manufacturers seeking to stay competitive in today’s market.

For those considering investing in CNC routing technology, the benefits are clear: improved quality, reduced costs, and increased productivity. As the demand for high-precision, customized components continues to grow, CNC routers will remain at the forefront of manufacturing innovation.

References

- International Journal of Advanced Manufacturing Technology – Study on CNC router precision.

- Woodworking Network – Report on CNC routers in furniture manufacturing.

- Signs of the Times – Case study on CNC routers in the signage industry.

- Journal of Materials Processing Technology – Study on CNC routers in aerospace manufacturing.

- Journal of Manufacturing Systems – Study on material waste reduction with CNC routers.

- Modern Machine Shop – Report on production time savings with CNC routers.