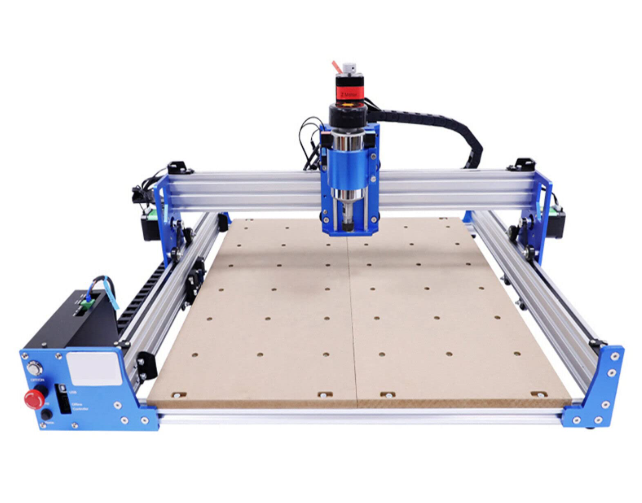

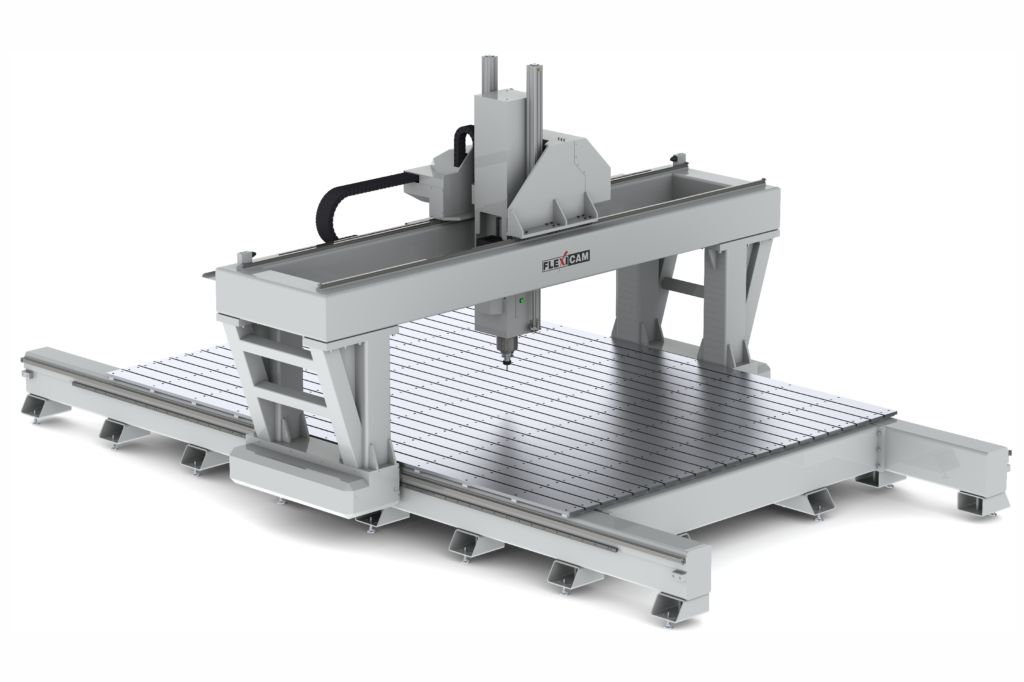

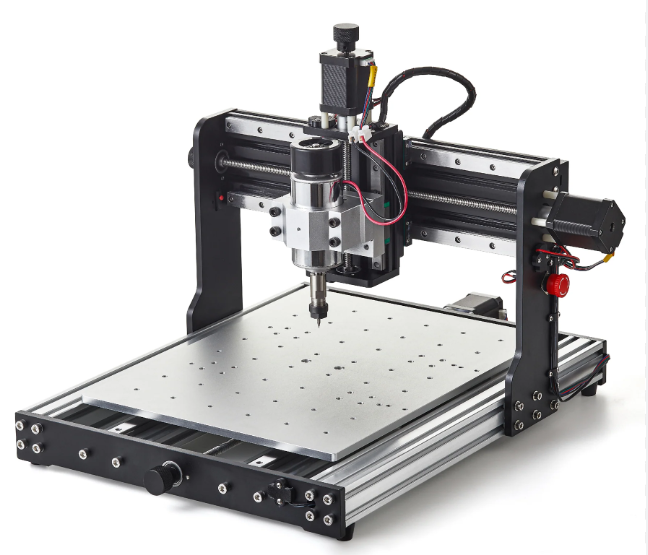

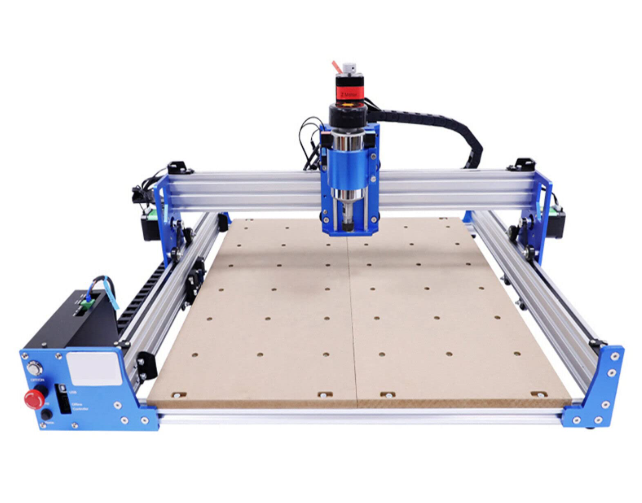

The CNC router machine represents a specialized category of computer-controlled cutting systems designed primarily for machining softer materials such as wood, plastics, and non-ferrous metals. These machines trace their technological lineage to traditional hand routers, with the critical distinction being their integration of computerized numerical control systems that enable precise, repeatable material removal operations. Unlike their industrial CNC milling counterparts designed for heavy metal cutting, router machines typically employ high-speed spindle systems optimized for rapid material removal in softer workpieces.

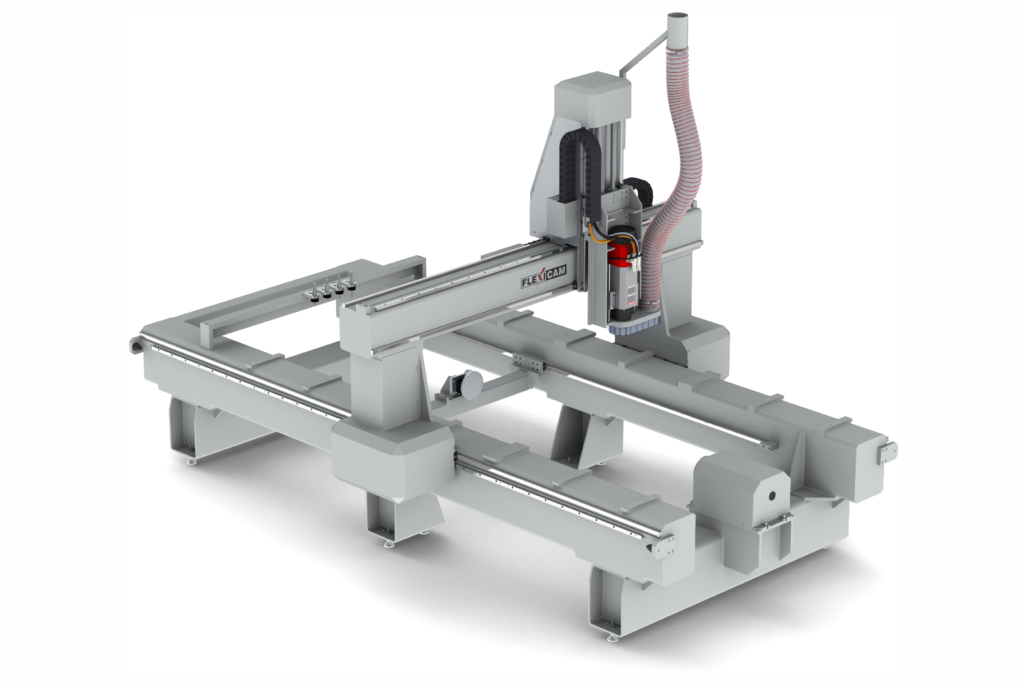

Modern CNC router systems operate on three primary linear axes (X, Y, Z) with positioning accuracies ranging from ±0.025 mm for entry-level machines to ±0.005 mm for industrial-grade equipment. The machine frame construction varies significantly by intended application – aluminum extrusion frames dominate the hobbyist and small business market, while welded steel frames with polymer concrete fill provide the vibration damping required for production environments. Linear motion systems typically incorporate profile rail guides with preloaded ball bearings, capable of maintaining straightness within 0.01 mm per 300 mm of travel under operational loads.

Modern CNC router systems operate on three primary linear axes (X, Y, Z) with positioning accuracies ranging from ±0.025 mm for entry-level machines to ±0.005 mm for industrial-grade equipment. The machine frame construction varies significantly by intended application – aluminum extrusion frames dominate the hobbyist and small business market, while welded steel frames with polymer concrete fill provide the vibration damping required for production environments. Linear motion systems typically incorporate profile rail guides with preloaded ball bearings, capable of maintaining straightness within 0.01 mm per 300 mm of travel under operational loads.

Spindle technology constitutes a critical differentiator among router machines. Standard configurations employ air-cooled induction motors with power ratings from 1.5 kW to 15 kW, achieving rotational speeds between 8,000 and 24,000 RPM. Advanced liquid-cooled spindles extend this range to 60,000 RPM for specialized applications requiring exceptionally fine detail work. The tool holding systems vary from basic collet chucks in smaller machines to hydraulic expansion chucks in industrial models, with runout specifications typically below 0.01 mm for quality systems.

Control systems in CNC routers have evolved significantly from early stepper motor-based designs to contemporary servo-driven configurations. Modern machines utilize 32-bit motion controllers capable of processing complex toolpaths at block processing rates exceeding 1,000 lines per second. The integration of look-ahead algorithms allows these systems to maintain cutting speeds up to 30 m/min while anticipating directional changes to prevent tool deflection or workpiece damage. Industrial models frequently incorporate additional features such as automatic tool changers with capacities ranging from 4 to 24 tools, significantly reducing non-cutting time between operations.

Workholding methods on CNC routers reflect the diversity of processed materials. Vacuum tables with zone control represent the most common solution, generating holding forces up to 80 N/cm² through regenerative blower systems. Mechanical clamping systems using toggle clamps or pneumatic actuators provide alternatives for irregularly shaped workpieces. Advanced production systems may incorporate automatic workpiece positioning with vision systems achieving placement accuracy within 0.1 mm.

The cutting tool selection for router applications demonstrates particular specialization. Solid carbide tools dominate the market, with geometries specifically optimized for material-specific chip evacuation. Compression spiral bits, featuring opposing helix angles along their cutting length, have become standard for panel processing as they simultaneously prevent tear-out on both the entry and exit surfaces of sheet materials. Diamond-coated tools extend tool life by factors of 3-5 when machining abrasive composites or high-pressure laminates.

Dust collection systems form an essential component of router installations, particularly given the voluminous chips generated during high-speed wood routing. Centralized collection systems with airflow rates of 5,000-20,000 m³/hr maintain adequate chip evacuation, while secondary HEPA filtration captures fine particulate matter below 10 microns in size. The integration of these systems with toolpath planning allows for optimized dust hood positioning during cutting operations.

Software ecosystems supporting CNC router operation have matured considerably. Contemporary CAD/CAM solutions offer specialized toolpath strategies for routing applications, including:

- Morphing between two curves for complex shape machining

- Rest machining routines that automatically identify remaining material from previous operations

- Advanced nesting algorithms that achieve material utilization rates exceeding 90% for panel goods

The industrial applications of CNC router machines span multiple sectors. In wood product manufacturing, they perform operations ranging from basic panel sizing to intricate decorative carving at production rates exceeding 100 sheets per shift. Sign-making industries utilize router systems for precision letter cutting in various plastic and aluminum substrates. The aerospace sector employs large-format routers for machining composite components, where the machines’ ability to maintain tolerances across multi-meter work envelopes proves critical.

Recent technological advancements continue to expand router capabilities. The integration of additive manufacturing heads enables hybrid manufacturing processes on a single platform. Improved thermal compensation systems counteract the effects of heat buildup during extended production runs. Machine learning algorithms now optimize feed rates dynamically based on real-time spindle load monitoring, increasing throughput while protecting tooling.

The economic aspects of CNC router ownership reveal distinct operational profiles. Industrial machines typically demonstrate return on investment periods of 12-24 months in production environments, with machine utilization rates often exceeding 85% in two-shift operations. Maintenance costs average 3-5% of initial machine cost annually, with spindle rebuilds representing the single largest recurring expense after approximately 15,000 operating hours.

Safety systems have evolved in parallel with machine capabilities. Current designs incorporate multiple redundant protections including:

- Light curtains preventing access to moving components

- Torque-limiting couplings on drive systems

- Automatic spindle braking achieving full stop within 2 seconds

- Software-based collision avoidance systems

The future development trajectory of CNC router technology points toward increased automation and connectivity. The implementation of Industrial Internet of Things (IIoT) protocols enables predictive maintenance through vibration and temperature monitoring. Automated material handling systems reduce labor requirements for loading and unloading operations. Continued improvements in cutting tool materials and coatings promise further gains in machining productivity and surface finish quality.

This ongoing technological evolution ensures CNC router machines maintain their position as versatile manufacturing solutions across diverse industries, adapting to new materials and production requirements while delivering the precision and repeatability expected of computer-controlled systems. Their unique combination of high-speed machining capabilities and large work envelopes continues to address manufacturing challenges that other CNC technologies cannot economically solve.