The advent of Computer Numerical Control (CNC) manufacturing marked a revolutionary shift in industrial production capabilities, transforming how components are designed and fabricated across global industries. This technology emerged from early numerical control systems developed in the late 1940s at the Massachusetts Institute of Technology, funded by the U.S. Air Force to produce complex aircraft components with greater precision than manual machining could achieve. The transition from mechanical automation to true CNC occurred in 1971 with the integration of minicomputer technology, enabling the processing of complex geometric data in real-time and establishing the foundation for modern computer-controlled manufacturing.

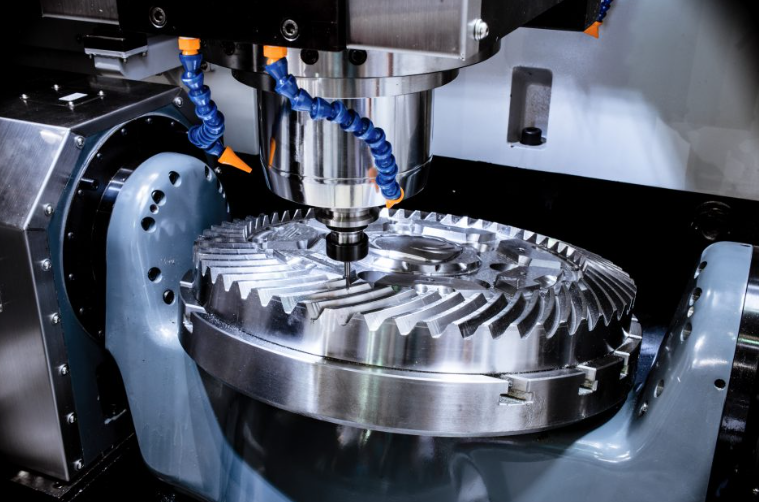

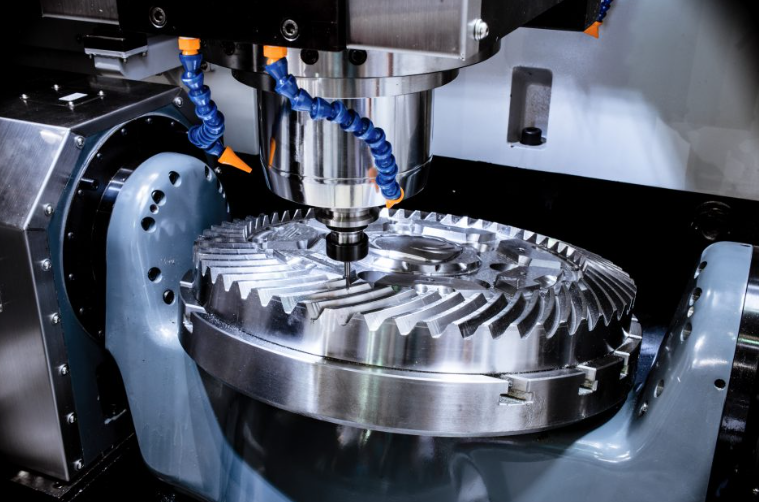

CNC systems operate through an intricate sequence of digital-to-physical translation processes that begin with computer-aided design (CAD) models. These digital representations define component geometry to exacting specifications, with commercial applications typically requiring ±0.025mm tolerances while aerospace components may demand ±0.0025mm precision. The CAD data undergoes processing through computer-aided manufacturing (CAM) software, where sophisticated algorithms generate optimized toolpaths accounting for material properties, cutting dynamics, and machine kinematics. The CAM system calculates appropriate spindle speeds ranging from 50 RPM for large diameter boring operations to 50,000 RPM for micro-milling applications, with feed rates carefully balanced between 0.1 m/min for finishing passes and 20 m/min for roughing operations in aluminum alloys.

CNC systems operate through an intricate sequence of digital-to-physical translation processes that begin with computer-aided design (CAD) models. These digital representations define component geometry to exacting specifications, with commercial applications typically requiring ±0.025mm tolerances while aerospace components may demand ±0.0025mm precision. The CAD data undergoes processing through computer-aided manufacturing (CAM) software, where sophisticated algorithms generate optimized toolpaths accounting for material properties, cutting dynamics, and machine kinematics. The CAM system calculates appropriate spindle speeds ranging from 50 RPM for large diameter boring operations to 50,000 RPM for micro-milling applications, with feed rates carefully balanced between 0.1 m/min for finishing passes and 20 m/min for roughing operations in aluminum alloys.

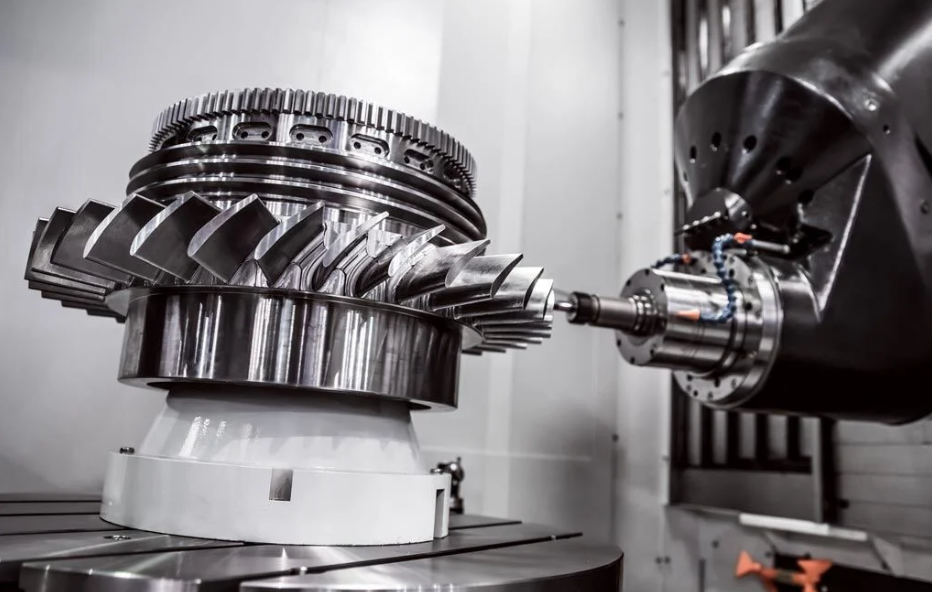

The mechanical architecture of CNC machine tools reflects rigorous engineering principles applied to achieve micron-level precision. Linear motion systems incorporate hardened steel guideways with preloaded ball bearings that maintain straightness within 0.01mm per 300mm of travel. Servo motors with absolute encoders provide positional feedback with resolutions reaching 0.1 micrometers, while ballscrews with pitch errors below 5 micrometers per 300mm ensure accurate axis movement. Spindle assemblies represent particularly critical components, with high-speed models utilizing ceramic hybrid bearings and liquid cooling to maintain rotational accuracy below 1 micrometer TIR at 30,000 RPM. The machine frame itself must provide exceptional rigidity, with polymer concrete fill now commonly used to damp vibrations that could compromise surface finishes.

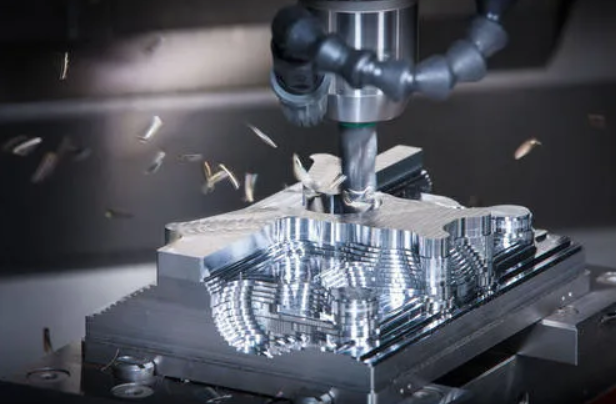

Tooling technology for CNC operations has advanced significantly to meet evolving manufacturing demands. Solid carbide end mills with specialized coatings like AlTiN withstand temperatures exceeding 800°C during high-speed machining of hardened steels. Modern tool geometries feature variable helix angles and unequal flute spacing to mitigate harmonic vibrations, enabling stable machining at length-to-diameter ratios exceeding 10:1. Automatic tool changers with 60+ station capacities and sub-2-second exchange times maximize machine utilization in production environments. Tool condition monitoring systems employ acoustic emission sensors and power consumption analysis to predict edge wear before dimensional accuracy degrades.

The programming languages governing CNC operations have evolved from simple G-code to sophisticated parametric programming. Contemporary controls support advanced features like spline interpolation for complex curvature machining and look-ahead algorithms that process hundreds of program blocks ahead to optimize feed rates during contouring. Five-axis simultaneous machining introduces additional computational complexity, with modern processors capable of executing millions of calculations per second to maintain tool center point control during intricate movements. Post-processors translate generic toolpath data into machine-specific instructions, accounting for unique kinematic configurations like tilting-rotary tables or trunnion-style work positioning.

Quality assurance in CNC manufacturing employs multiple verification methodologies. On-machine probing systems measure workpiece features with 1-micron repeatability, enabling in-process adjustments that compensate for thermal growth or tool wear. Laser interferometers periodically verify machine geometry, detecting positional errors as small as 0.5 micrometers per meter of axis travel. Surface finish analysis using contact profilometers quantifies roughness averages (Ra) down to 0.05 micrometers for precision components. Statistical process control tracks key variables including dimensional variation and tool life, maintaining process capability indices (Cpk) above 1.67 for critical aerospace applications.

Industrial applications of CNC technology span virtually every manufacturing sector. Automotive production utilizes transfer lines with dozens of CNC stations performing sequential operations on engine blocks and transmission cases. Medical device manufacturers employ Swiss-type lathes with guide bushings to machine bone screws with 0.005mm tolerances. The mold and die industry relies on high-speed machining centers with 30,000 RPM spindles to mill hardened tool steels to mirror finishes. Aerospace manufacturers operate gantry mills with 20-meter work envelopes to machine monolithic wing spars from aluminum billets. Energy sector applications include CNC-controlled pipe bending machines that form offshore risers with precise curvature control.

Recent technological advancements continue expanding CNC capabilities. Additive manufacturing integration allows hybrid machines to alternately deposit and machine material, creating complex internal geometries impossible with subtractive methods alone. Artificial intelligence applications analyze vast datasets from machine monitoring systems to optimize cutting parameters in real-time. Digital twin technology creates virtual replicas of CNC equipment that simulate machining processes before physical production begins. IoT connectivity enables predictive maintenance by tracking spindle vibration signatures and ball screw wear patterns.

The economic impact of CNC manufacturing is reflected in global market metrics. Industry reports value the worldwide CNC machine tool market at $83 billion in 2023, with projected compound annual growth of 6.5% through 2030. Labor productivity in CNC operations exceeds conventional machining by factors of 3-5, while material utilization improvements reduce waste by up to 40% through optimized nesting algorithms. The technology’s precision capabilities have enabled weight reductions of 15-20% in aerospace components through topological optimization and thin-wall machining.

Environmental considerations have driven significant process improvements in CNC operations. Minimum quantity lubrication systems reduce cutting fluid consumption by 90% compared to flood cooling. Energy recovery systems capture braking energy from axis motors, returning up to 30% of power consumption to the electrical grid. Chip management systems separate and sort metal swarf for efficient recycling, achieving recovery rates exceeding 99% for valuable alloys. Newer machine designs incorporate thermal stabilization features that maintain accuracy while reducing energy-intensive climate control requirements.

Workforce development remains crucial for advancing CNC manufacturing. Modern machinists require skills spanning traditional metrology, CAD/CAM programming, and data analytics. Training programs increasingly incorporate virtual reality simulations that allow safe practice of complex setups before operating physical equipment. Certification standards like NIMS (National Institute for Metalworking Skills) validate competencies in CNC operation, programming, and maintenance across multiple proficiency levels.

The future trajectory of CNC manufacturing points toward greater autonomy and connectivity. Developments in machine learning promise self-optimizing systems that adapt cutting strategies based on real-time sensor feedback. Advanced robotics integration enables lights-out manufacturing with automated workpiece loading and unloading. Quantum computing applications may eventually solve complex toolpath optimization problems currently requiring hours of computation in seconds. These innovations will further cement CNC technology’s central role in global manufacturing ecosystems while continuing to push the boundaries of precision, efficiency, and capability.