China has emerged as a global leader in CNC machining, establishing itself as a dominant force in precision manufacturing across industries ranging from aerospace to consumer electronics. The country’s CNC machining capabilities trace their origins to the late 1970s when China began importing its first computer-controlled machine tools from Japan and Germany. This marked the beginning of a technological transformation that would see China evolve from basic manual machining operations to becoming the world’s largest producer and consumer of CNC equipment by the early 21st century.

The growth of China’s CNC machining sector has been fueled by substantial government support through initiatives like the “Made in China 2025” plan, which prioritized advanced manufacturing technologies. Industrial clusters specializing in precision machining developed in key regions, most notably in the Pearl River Delta (Guangdong province), Yangtze River Delta (Jiangsu/Zhejiang), and Bohai Economic Rim (Shandong). These manufacturing hubs now house thousands of CNC machining facilities equipped with multi-axis machining centers, Swiss-type lathes, and specialized equipment for processing everything from medical implants to automotive components.

Chinese CNC shops typically operate with a vertical integration model that provides significant competitive advantages. A single facility might house 50 to 300 CNC machines from domestic brands like Shenyang Machine Tool or international manufacturers such as DMG Mori and Mazak. This is complemented by in-house tooling departments, quality control labs with CMMs (Coordinate Measuring Machines), and often even metal finishing services. The average Chinese CNC machining business maintains an equipment renewal cycle of 5-7 years, ensuring relatively modern machine tool technology across the industry.

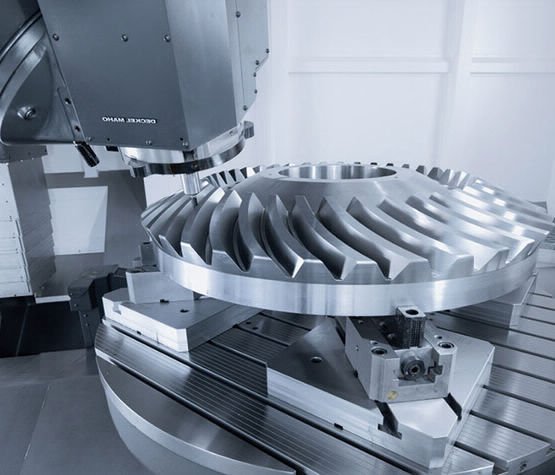

The technical capabilities of Chinese CNC machining providers have reached globally competitive levels. Precision tolerances of ±0.01mm are routinely achieved for aerospace and medical applications, with some specialty shops capable of holding ±0.005mm for optical components. Five-axis simultaneous machining has become commonplace in major production centers, enabling complex contouring operations on turbine blades and impellers. High-speed machining of aluminum alloys at spindle speeds exceeding 20,000 RPM with feed rates of 15-20 m/min represents standard practice in many facilities serving the electronics industry.

Material expertise represents another area where Chinese CNC machining has developed particular strengths. While early operations focused primarily on steel and aluminum alloys, contemporary shops demonstrate proficiency with:

- Titanium alloys for aerospace applications

- Inconel and other nickel-based superalloys

- Engineering plastics like PEEK and Ultem

- Advanced composites including carbon fiber reinforced polymers

This materials knowledge is supported by China’s domestic supply chain for metal stock, with specialized mills producing precision ground bar stock and custom extruded profiles tailored for CNC machining applications.

Quality systems in Chinese CNC machining facilities have undergone significant maturation. Where early operations relied heavily on manual inspection, modern shops implement comprehensive quality management systems. ISO 9001 certification has become nearly universal among export-oriented machining providers, with many aerospace suppliers achieving AS9100 compliance. On-machine probing, laser tool setters, and automated inspection stations have become standard equipment, while statistical process control (SPC) methods are widely adopted for production monitoring.

The workforce supporting China’s CNC machining industry has developed through a combination of vocational education and on-the-job training. Technical schools across manufacturing regions graduate thousands of CNC operators annually, with curricula covering G-code programming, CAD/CAM software operation, and precision measurement techniques. Experienced machinists in China’s major industrial cities typically command salaries 30-50% higher than general manufacturing workers, reflecting the specialized skills required. Many facilities now employ engineering graduates who bridge the gap between design and production, optimizing parts for manufacturability.

China’s CNC machining sector has particularly excelled in serving global supply chains. The country has become the preferred manufacturing base for:

- Automotive components (engine parts, transmission components)

- Industrial automation equipment (linear guides, robotic arms)

- Medical devices (surgical instruments, implantable components)

- Consumer electronics (enclosures, heat sinks, connectors)

This export orientation has driven continuous improvement in manufacturing standards, with many Chinese shops achieving certifications from European and North American OEMs. Lead times have become increasingly competitive, with rapid prototyping services offering 1-3 day turnaround and production runs shipping within 2-4 weeks being standard practice.

Technological adoption in Chinese CNC machining has accelerated in recent years. Industry 4.0 concepts are being implemented, with:

- Machine monitoring systems tracking OEE (Overall Equipment Effectiveness)

- Digital twin technology for process simulation

- Automated guided vehicles (AGVs) for material handling

- Cloud-based production management platforms

These digital transformation initiatives are supported by China’s robust industrial IoT ecosystem and widespread 5G infrastructure in manufacturing regions.

The economic scale of CNC machining in China is staggering. The country accounts for approximately 30% of global machine tool consumption annually, with domestic CNC equipment sales exceeding 200,000 units per year. Chinese CNC machining service providers generate an estimated $50 billion in annual revenue, serving both domestic and international markets. Pricing remains competitive, typically 30-50% lower than Western counterparts for comparable precision work, though this gap narrows for highly specialized applications requiring extreme tolerances or exotic materials.

Environmental considerations are increasingly shaping China’s CNC machining practices. Newer facilities incorporate:

- Centralized coolant filtration and recycling systems

- Energy-efficient servo motors and drives

- Waste heat recovery technology

- Sustainable cutting fluid alternatives

Government regulations now mandate proper disposal of metalworking fluids and chips, driving more environmentally responsible practices across the industry.

Looking forward, China’s CNC machining sector continues to evolve through several key trends:

- Increased automation with robotic loading/unloading systems

- Expanded use of domestic high-end CNC machine tools

- Growth in hybrid manufacturing combining additive and subtractive processes

- Specialization in difficult-to-machine materials

- Further digital integration across the production chain

This ongoing development ensures China maintains its position as the world’s most comprehensive CNC machining base, capable of serving everything from high-volume production runs to low-volume, high-complexity precision components. The combination of technical capability, supply chain depth, and competitive economics makes Chinese CNC machining an enduring pillar of global manufacturing.