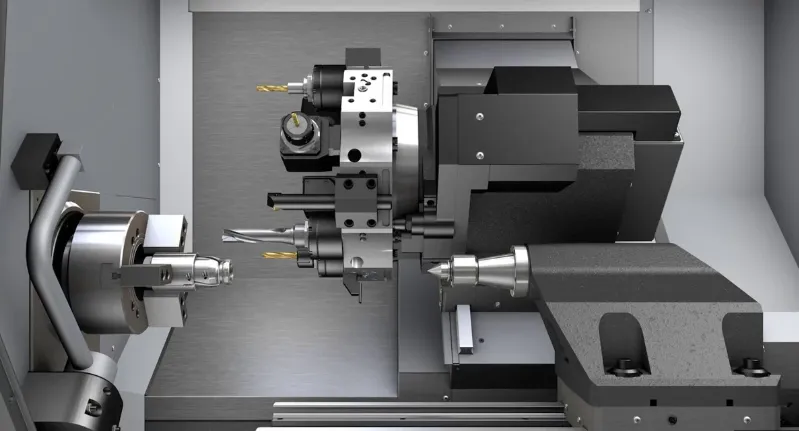

Machine Construction and Framework

CNC lathes feature a heavy-duty cast iron bed that provides exceptional vibration damping and thermal stability. The machine’s base supports precision-ground linear guideways that ensure smooth movement of the carriage and turret assemblies. A rigid headstock housing contains the main spindle assembly, typically supported by high-precision angular contact bearings capable of maintaining tight runout tolerances under heavy cutting loads.

Control System Operation

Control System Operation

The CNC system operates through an industrial-grade computer running specialized machine control software. This software interprets G-code programs and converts them into electrical signals that drive servo motors with positional accuracy down to 0.1 microns. Modern controllers incorporate multi-core processors that simultaneously manage axis movements, spindle control, tool changes, and auxiliary functions while providing real-time monitoring of all machine parameters.

Cutting Tool Configuration

A typical CNC lathe turret holds between 8 and 24 tools in quick-change holders. Live tooling stations allow for milling and drilling operations without removing the workpiece. Tool presetters measure exact tool geometry, with this data automatically loaded into the machine’s tool offset registry. Advanced machines feature automatic tool wear compensation systems that adjust cutting parameters based on real-time sensor feedback.

Material Processing Capabilities

These machines process a wide range of materials:

- Steel alloys: Cutting speeds from 100-400 surface feet per minute (SFM)

- Aluminum: 300-1000 SFM with appropriate tooling

- Titanium alloys: Requiring specialized tool geometries and reduced speeds (50-150 SFM)

- Plastics: Processed at higher speeds with specialized chip-breaking tooling

Precision Machining Operations

Standard operations include:

- Rough turning with depth of cut up to 6mm

- Finish turning achieving surface finishes to 0.4μm Ra

- Thread cutting with pitch accuracy within 0.01mm

- Grooving operations with width tolerances of ±0.005mm

- Drilling and boring operations with positional accuracy to 0.002mm

Automation Integration

Modern CNC lathes interface with:

- Robotic loaders handling parts up to 50kg

- Gantry systems for larger workpieces

- Conveyor systems for chip removal

- Automated measurement devices for in-process inspection

- Factory network systems for production monitoring

Safety Systems Implementation

Comprehensive safety features include:

- Light curtain protection at access points

- Hydraulic chuck pressure monitoring

- Tool collision detection systems

- Emergency stop circuits with redundant monitoring

- Chip containment guards with interlocks

Maintenance Requirements

Regular maintenance involves:

- Daily lubrication system checks

- Weekly way cover inspections

- Monthly spindle bearing condition monitoring

- Quarterly ball screw backlash measurements

- Annual electrical system testing

Technological Advancements

Recent developments include:

- Integrated workpiece measurement probes

- AI-based tool wear prediction systems

- Energy recovery systems for servo drives

- Cloud-based machine monitoring platforms

- Augmented reality maintenance assistance

Industrial Applications

Primary application sectors:

- Automotive component manufacturing (axles, hubs)

- Aerospace part production (landing gear components)

- Medical device fabrication (bone screws, implants)

- Energy sector applications (valve bodies, fittings)

- Defense industry parts (munitions, weapon components)

Environmental Considerations

Modern machines incorporate:

- High-efficiency spindle motors

- Coolant recycling systems

- Chip compaction units

- Energy-saving standby modes

- Low-emission cutting processes

Operator Interface Features

Control panels typically offer:

- 15-24″ touchscreen displays

- 3D toolpath simulation

- Conversational programming

- Multi-language support

- Remote access capabilities

Quality Assurance Systems

Integrated quality control includes:

- In-process gauging systems

- Tool breakage detection

- Adaptive control systems

- Statistical process control

- Full machining documentation

Workholding Options

Available configurations:

- Hydraulic chucks with 3-6 jaws

- Collet chuck systems

- Faceplate fixtures

- Between-center turning

- Specialized mandrels

Coolant System Technology

Advanced systems feature:

- High-pressure through-tool delivery

- Minimum quantity lubrication

- Temperature control

- Filtration to 5 microns

- Automated concentration monitoring

Electrical System Specifications

Power requirements typically:

- 3-phase 400V power supply

- 15-100kVA transformer

- Regenerative drive systems

- Uninterruptible control power

- Shielded cable routing

Software Ecosystem

Supporting software includes:

- CAD/CAM integration packages

- Simulation software

- Tool management systems

- Production monitoring

- Maintenance scheduling

Global Standards Compliance

Machines meet:

- ISO 13041 safety standards

- CE marking requirements

- Country-specific electrical codes

- Environmental regulations

- Quality management systems

Economic Production Factors

Key considerations:

- Machine hour rate calculations

- Tooling cost per part

- Energy consumption

- Floor space requirements

- Operator productivity

Future Development Trends

Emerging technologies:

- Digital twin integration

- Advanced material machining

- Nanotechnology applications

- Hybrid manufacturing

- Increased automation

Educational Applications

Training implementations:

- Engineering school labs

- Vocational training centers

- Apprenticeship programs

- Industry certification

- Continuous education

Service and Support

Aftermarket services:

- Field technician support

- Spare parts inventory

- Software updates

- Retrofit options

- Technical hotlines