Computer Numerical Control (CNC) drilling has become a cornerstone in contemporary manufacturing, offering unparalleled precision, repeatability, and efficiency. This article explores the fundamentals of CNC drilling, its applications across various industries, the tangible benefits it provides, and the challenges it faces. By integrating recent industry data and real-world examples, we highlight the pivotal role CNC drilling plays in advancing manufacturing processes and shaping the future of production.

Introduction

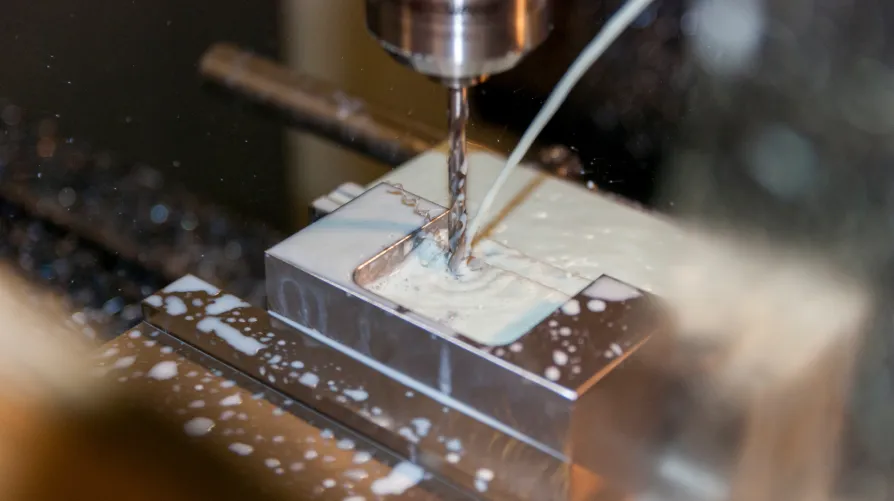

In the competitive landscape of modern manufacturing, precision and efficiency are paramount. CNC drilling stands out as a critical technology that meets these demands, enabling manufacturers to produce complex components with high accuracy and consistency. From automotive and aerospace to electronics and medical devices, CNC drilling has revolutionized production methods, enhancing product quality and reducing operational costs.

Evolution of CNC Drilling

CNC drilling has evolved significantly since its inception in the mid-20th century. Initially, drilling processes were manual, relying heavily on skilled technicians to achieve desired outcomes. The introduction of Computer Numerical Control in the 1950s marked a significant breakthrough, allowing for programmable controls that automated drilling tasks.

By the 1980s, advancements in computer technology and electronics led to more sophisticated CNC machines capable of multi-axis operations, enhancing the complexity and precision of drilled components. Today, CNC drilling machines are integrated with advanced software, Internet of Things (IoT) devices, and artificial intelligence (AI) algorithms, enabling real-time monitoring, adaptive control, and predictive maintenance.

Technical Aspects of CNC Drilling

CNC drilling operates by converting digital designs into machine-readable instructions, typically using G-code or M-code. The key components of a CNC drilling system include:

- Controller Unit: The brain of the CNC machine, interpreting programmed instructions to guide the drilling process.

- Spindle: Rotates the drill bit at precise speeds, essential for cutting through various materials.

- Axes Movement: Most CNC drilling machines operate on multiple axes (commonly three: X, Y, and Z) to position the drill accurately over the workpiece.

- Tool Magazine: Stores and switches between different drill bits automatically, allowing for versatile drilling tasks.

- Feedback Systems: Incorporate sensors and real-time monitoring to ensure precision and adjust parameters dynamically during the drilling process.

Modern CNC drills often feature integrated cooling systems, automated tool changers, and advanced safety mechanisms to enhance performance and reliability.

Applications Across Industries

CNC drilling’s versatility makes it indispensable across numerous sectors:

Automotive Industry

In automotive manufacturing, CNC drilling is crucial for producing engine components, chassis parts, and electronic assemblies. For example, cylinder heads require multiple holes drilled with micron-level precision to ensure proper sealing and performance. Companies like Toyota and BMW utilize CNC drilling to maintain high standards of quality and efficiency in their production lines.

Aerospace Sector

The aerospace industry demands stringent tolerances and high-quality standards. CNC drilling is used to fabricate components such as turbine blades, fuselage sections, and landing gear parts. Boeing and Airbus integrate CNC drilling in their manufacturing processes to achieve the necessary precision and reliability for aircraft safety and performance.

Electronics Manufacturing

Printed Circuit Boards (PCBs) rely heavily on CNC drilling for creating intricate hole patterns that accommodate densely packed electronic components. The miniaturization trend in electronics, driven by consumer demand for smaller and more powerful devices, makes CNC drilling indispensable. Companies like Intel and Samsung employ CNC drilling to meet the high-precision requirements of modern electronics.

Medical Devices

In the medical industry, CNC drilling ensures the manufacturing of precise components for implants, surgical instruments, and diagnostic equipment. For instance, orthopedic implants require exacting hole placements to ensure compatibility and functionality, enhancing patient outcomes and device longevity.

Advantages of CNC Drilling

High Precision and Accuracy

CNC drilling machines can achieve tolerances as tight as ±0.001 inches, significantly reducing dimensional errors and ensuring that each component meets exact specifications. This level of precision is critical in industries where even minor deviations can compromise product performance and safety.

Consistency and Repeatability

Automated CNC drilling processes ensure that each drilled part is identical, minimizing variability across large production runs. This consistency is vital for maintaining quality standards and reducing the need for extensive quality control measures.

Increased Efficiency

CNC drilling reduces cycle times by optimizing tool paths and minimizing manual interventions. For example, a CNC machine can complete a set of 1,000 holes in a fraction of the time it would take manually, enhancing overall production throughput.

Flexibility and Adaptability

CNC drilling systems can be quickly reprogrammed to accommodate different drilling patterns and workpiece geometries, allowing manufacturers to adapt to changing production requirements without significant downtime.

Cost Savings

By reducing material wastage and minimizing the need for manual labor, CNC drilling contributes to significant cost savings. Additionally, the decreased incidence of errors and defects lowers overall production costs and enhances profitability.

Real-World Data and Impact

According to a 2023 report by MarketsandMarkets, the global CNC machine tool market is projected to reach $125.98 billion by 2027, growing at a compound annual growth rate (CAGR) of 14.2% from 2022. CNC drilling constitutes a significant portion of this market, driven by the increasing demand for high-precision components across various industries.

In the automotive sector, the adoption of CNC drilling has led to a 20% increase in production efficiency and a 15% reduction in defect rates. Similarly, in electronics manufacturing, CNC drilling has enabled manufacturers to achieve drilling accuracies that support the miniaturization of components, aligning with the trend towards more compact and powerful devices.

A study by the International Manufacturing Technology Association (IMTA) in 2023 revealed that companies utilizing CNC drilling reported a 30% decrease in labor costs due to automation and a 25% increase in production capacity, underscoring the technology’s significant impact on operational efficiency and cost management.

Challenges and Limitations

Initial Investment

The cost of acquiring advanced CNC drilling machines, along with the necessary training for operators, can be substantial. This initial investment can be a barrier for small and medium-sized enterprises (SMEs) looking to adopt CNC drilling technology.

Maintenance and Downtime

CNC machines require regular maintenance to function optimally. Unexpected breakdowns can lead to production delays and increased operational costs. Implementing robust maintenance schedules and investing in predictive maintenance technologies can mitigate these risks.

Complexity of Programming

While CNC machines offer high levels of automation, setting up complex drilling patterns still requires skilled programmers. This complexity can limit accessibility for manufacturers without the necessary technical expertise, potentially necessitating additional training or hiring specialized personnel.

Material Limitations

Certain materials, particularly those that are extremely hard or brittle, can pose challenges for CNC drilling. Achieving the desired precision without damaging the workpiece requires specialized drill bits and optimized drilling parameters, which may increase production complexity and costs.

Future Trends

Integration with Artificial Intelligence and Machine Learning

AI and machine learning algorithms are poised to enhance CNC drilling by optimizing drilling parameters in real-time, predicting tool wear, and preventing potential failures. These technologies enable smarter, more adaptive machining processes that improve efficiency and reduce downtime.

Additive and Subtractive Hybrid Manufacturing

Combining CNC drilling with additive manufacturing techniques allows for the production of complex, multi-material components that are difficult to achieve with traditional methods alone. This hybrid approach opens new possibilities for innovation in product design and manufacturing.

Sustainable Manufacturing Practices

As sustainability becomes a critical focus, CNC drilling technologies are evolving to incorporate eco-friendly materials and energy-efficient processes. Advances in cooling systems and the use of biodegradable lubricants contribute to reducing the environmental impact of CNC drilling operations.

Advanced Automation and IoT Integration

The integration of IoT devices with CNC drilling machines facilitates real-time monitoring, data collection, and remote management. This connectivity supports proactive maintenance, enhances operational transparency, and enables continuous improvement in manufacturing processes.

Enhanced User Interfaces and Accessibility

Developments in user interface design are making CNC drilling machines more accessible to operators with varying levels of technical expertise. Intuitive software and automated setup processes reduce the learning curve, making advanced CNC drilling technology more widely adoptable.

Conclusion

CNC drilling has established itself as a fundamental technology in modern manufacturing, offering unmatched precision, efficiency, and adaptability. Its applications across diverse industries underscore its versatility and critical importance in producing high-quality components. While challenges such as initial investment and programming complexity exist, ongoing advancements in AI, hybrid manufacturing, and sustainable practices are poised to address these issues and further enhance the capabilities of CNC drilling.

As manufacturing continues to evolve towards greater automation and smart technologies, CNC drilling will remain at the forefront, driving innovation and excellence. Manufacturers who embrace these advancements stand to gain significant competitive advantages, positioning themselves for success in an increasingly demanding and dynamic global market.