The Unmatched Precision of CNC Broaching

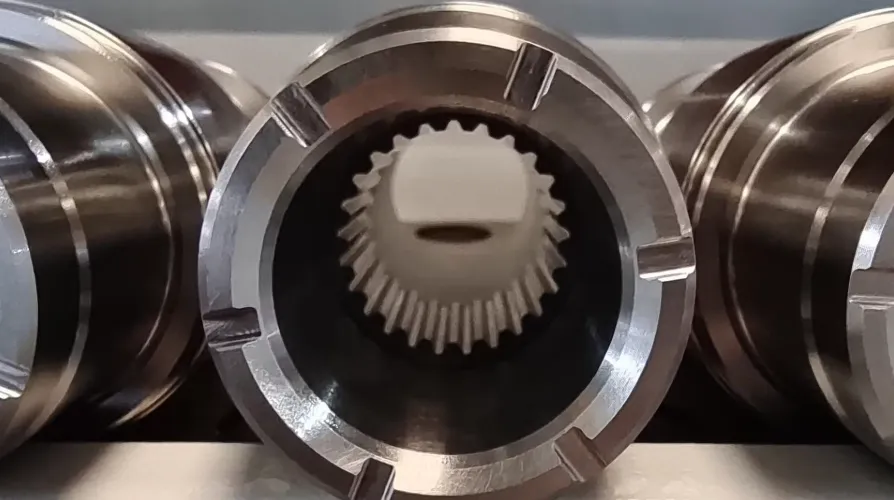

Unlike conventional machining methods, CNC broaching delivers unparalleled accuracy in producing internal keyways, splines, and non-circular profiles. Modern CNC broaching machines achieve tolerances as tight as ±0.003 mm (0.0001 inches) for critical components like aircraft landing gear and automotive transmission systems.

How CNC Broaching Works

How CNC Broaching Works

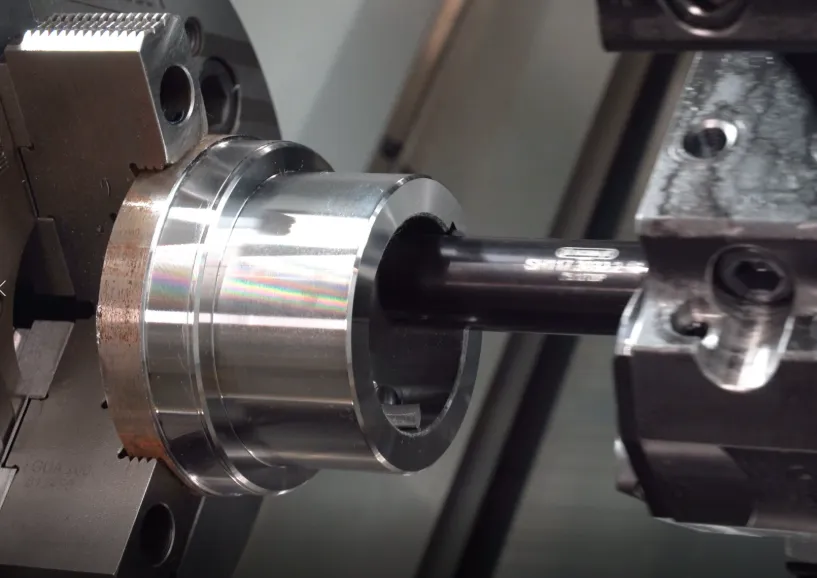

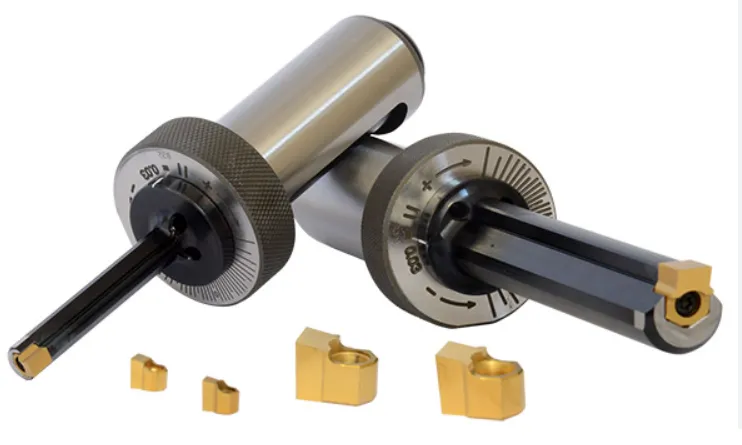

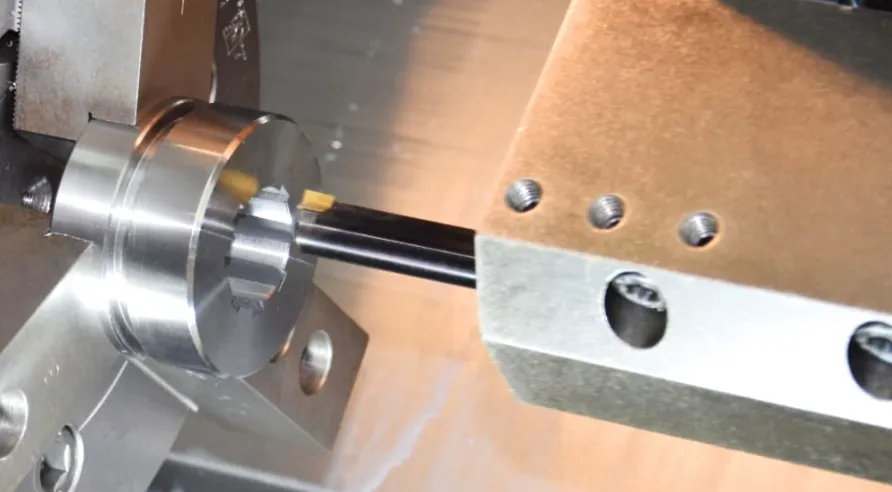

The process uses a multi-tooth, progressively cutting tool (broach) that removes material in a single linear pass. Key advantages include:

- One-Pass Machining – Eliminates multiple operations, reducing cycle times by 40-60% compared to milling or shaping

- Superior Surface Finish – Achieves Ra 0.4-0.8 μm without secondary polishing

- Material Versatility – Effectively machines hardened steels (up to 60 HRC), titanium alloys, and composites

Cutting-Edge Innovations

- Adaptive Force Control – Sensors adjust cutting pressure in real-time, extending tool life by 30%

- Linear Motor Drives – Enable faster strokes (up to 120 m/min) with near-zero backlash

- Hybrid Broaching – Combines rotary and linear motion for helical splines in single setup

Industry-Specific Applications

- Aerospace: Turbine disc fir-tree slots

- Automotive: Gearbox internal splines

- Medical: Implant hexagonal drive sockets

Market Outlook

The CNC broaching equipment market is forecast to reach $1.2 billion by 2027 (6.1% CAGR), fueled by EV gearbox production and defense sector demand. Leaders like American Broach & Machine and Forst Technologies are pioneering:

- AI-Powered Predictive Maintenance – Reduces unplanned downtime by 25%

- Ultra-Hard Broach Coatings – TiAlN-coated tools last 5x longer in Inconel machining

Overcoming Technical Challenges

- Chip Evacuation – High-pressure coolant systems (70 bar) prevent recutting

- Tool Deflection – Stiffened guideways maintain 0.005 mm/m straightness

Why CNC Broaching Outperforms Alternatives

| CNC Broaching | CNC Milling | EDM | |

|---|---|---|---|

| Speed | 5-10x faster | Moderate | Slowest |

| Accuracy | ±0.003 mm | ±0.01 mm | ±0.002 mm |

| Surface Finish | Mirror-ready | Requires finishing | Heat-affected zone |

The Future: Smart Broaching Systems

Next-gen machines will feature:

- Digital Twin Integration – Simulates tool wear before physical cuts

- Nanostructured Broaches – Cutting edges remain sharp for 1 million+ cycles