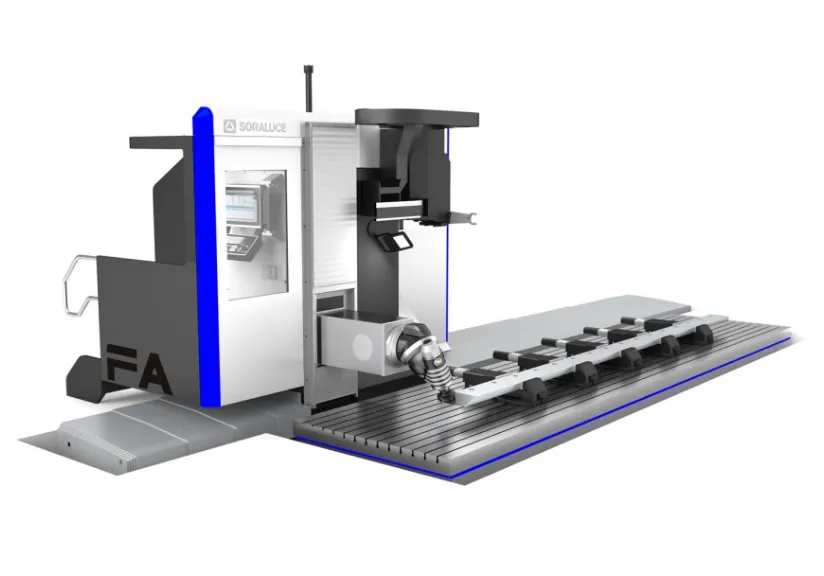

CNC boring machines are specialized machine tools designed for high-precision hole enlargement, finishing, and internal machining operations. These machines play a critical role in industries requiring tight-tolerance components, such as aerospace, automotive, and heavy equipment manufacturing.

Technology and Operation

Modern CNC boring machines utilize programmable controls to achieve accuracies within ±0.005 mm (0.0002 inches) on bore diameters. The latest models incorporate linear motor drives, reducing backlash and improving positioning repeatability to 0.001 mm. Unlike conventional drilling, boring operations refine pre-existing holes to exact specifications, making them indispensable for engine blocks, hydraulic cylinders, and turbine housings.

Key Features and Advancements

- Spindle Technology – High-frequency spindles (up to 20,000 RPM) with HSK or CAT tapers ensure stability during heavy cutting.

- Automated Tool Changers – Reduce downtime with 60+ tool magazines for uninterrupted production.

- In-Process Measurement – Probing systems verify bore dimensions in real-time, correcting tool wear automatically.

- Multi-Axis Capability – 5-axis CNC boring machines enable complex internal geometries without repositioning.

Industry Applications

- Aerospace – Boring turbine casings to ±0.01 mm tolerances.

- Automotive – Machining cylinder liners for diesel engines.

- Energy Sector – Finishing large-diameter valve bodies for oil & gas applications.

Market Trends

The global CNC boring machine market is projected to grow at 5.2% CAGR (2024-2030), driven by demand for high-precision components in electric vehicles and renewable energy systems. Leading manufacturers like Toshiba, UNION, and FPT Industrie are integrating AI-driven adaptive machining to optimize feed rates and reduce cycle times by 15-20%.

Challenges and Solutions

- Thermal Deformation – Advanced coolant systems maintain ±1°C temperature stability.

- Vibration Control – Active damping systems minimize harmonic distortion during deep boring.

Conclusion

CNC boring machines remain essential for precision manufacturing, combining automation, rigidity, and cutting-edge metrology. As industries push for tighter tolerances, innovations in smart boring systems will continue to redefine machining efficiency.