Chamfer bits are an essential tool in both woodworking and metalworking, renowned for their capability to create angled edges or bevels on materials. These bits are not only instrumental in improving the aesthetic appeal of joints and edges but also play a significant role in enhancing the functionality and safety of various components. This article delves into the details of chamfer bits, their types, applications, and best practices for use.

What Is a Chamfer Bit?

What Is a Chamfer Bit?

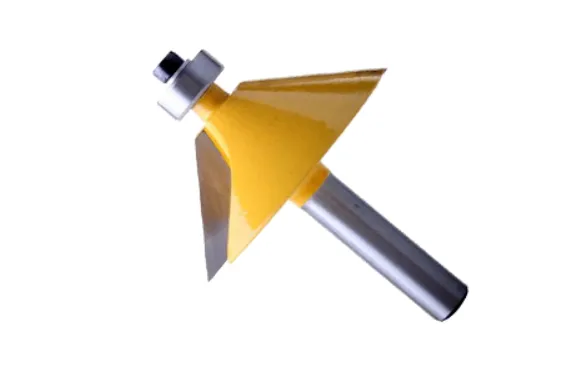

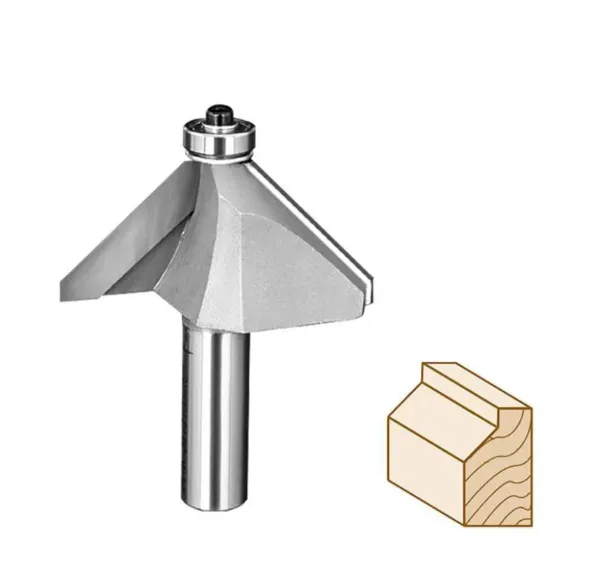

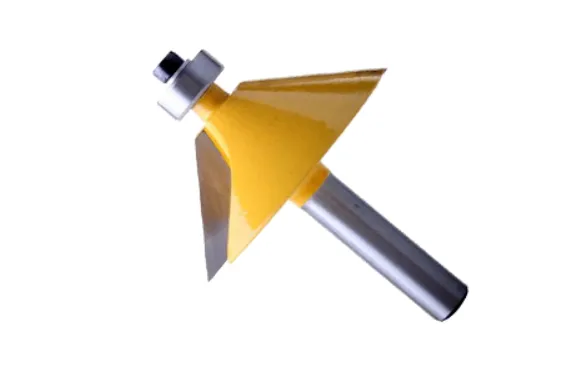

A chamfer bit is a specialized cutting tool designed to cut a beveled edge or shoulder on a workpiece. Typically used in routers for woodworking, these bits feature a cutting edge that is angled, allowing for precise cuts. The most common angles for chamfer bits range from 15 to 45 degrees, although custom angles can also be produced for specific applications. They can be found in various materials, including carbide for durability and longevity.

Types of Chamfer Bits

Chamfer bits come in several styles, each suited to different tasks:

-

Straight Chamfer Bits: These bits have a simple straight edge and are commonly used for creating clean beveled edges on wood or metal.

-

Cove Chamfer Bits: These bits feature a curved profile, allowing for more complex designs. They are ideal for creating decorative edges or features on furniture.

-

Offset Chamfer Bits: With an offset design, these bits allow access to tighter spaces. They are particularly useful when working on multi-layered or complex assemblies.

-

Multiple Flute Chamfer Bits: These bits have several cutting edges, enabling faster cuts and smoother finishes. They are often employed in production environments where efficiency is critical.

Applications of Chamfer Bits

Chamfer bits serve a variety of purposes across different industries:

-

Woodworking: In furniture making, chamfer bits are used to soften edges and create visual interest. They can also be used in cabinetry to facilitate better fitting joints.

-

Metalworking: Chamfering edges on metal parts helps in deburring, ensuring smoother assembly and reducing the risk of injury from sharp edges. Additionally, chamfered edges improve the welding surface, enhancing joint strength.

-

Construction: In construction, chamfer bits are used to prepare edges for installation, particularly in door frames and window sills where aesthetics and proper alignment are critical.

Tips for Using Chamfer Bits

To achieve the best results with chamfer bits, consider the following tips:

-

Choose the Right Bit: Select a chamfer bit that matches the desired bevel angle and material type. This will ensure a clean and precise cut.

-

Set the Correct Speed: Adjust the router’s speed according to the material being cut. Typically, harder materials require slower speeds, while softer materials can be cut at higher speeds.

-

Feed Rate: Maintain a steady feed rate. Too fast can cause burning and chipping, while too slow can lead to unnecessary wear on the bit.

-

Practice Safety: Always wear appropriate protective gear and ensure the workpiece is securely clamped. A safe work environment is crucial for avoiding accidents.

-

Test Cuts: Before making final cuts on your workpiece, conduct a few test runs on scrap material. This helps to ensure that the angle and depth of the chamfer are as desired.

Conclusion

Chamfer bits are versatile tools that enhance the quality and appearance of both woodworking and metalworking projects. Whether you are a professional craftsman or a DIY enthusiast, understanding how to effectively use chamfer bits can elevate your work to new heights. From creating intricate designs to ensuring tight joints, these bits are a valuable addition to any toolkit. With the right knowledge and practice, anyone can achieve beautiful, functional results using chamfer bits.