Precision Tailored: The Impact of Custom Machined Parts in Modern Industry

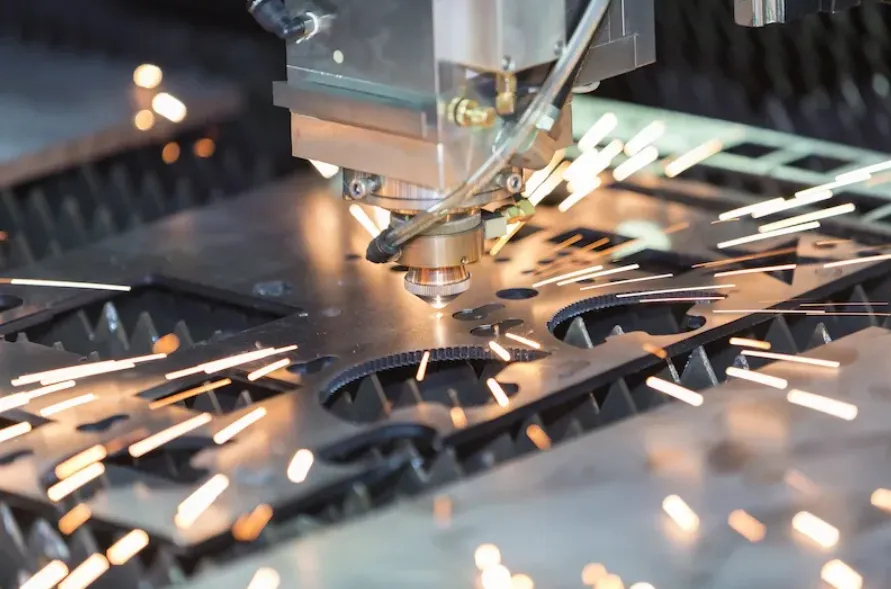

In the intricate world of manufacturing, custom machined parts have emerged as pivotal components driving innovation and efficiency across diverse industries.

In the intricate world of manufacturing, custom machined parts have emerged as pivotal components driving innovation and efficiency across diverse industries.

In the dynamic landscape of modern manufacturing, knee milling machines emerge as indispensable assets, seamlessly blending precision, versatility, and robustness to meet diverse industrial demands.

Anodizing aluminum is a pivotal electrochemical process that significantly augments the metal’s natural properties, making it exceptionally suitable for a wide range of applications.

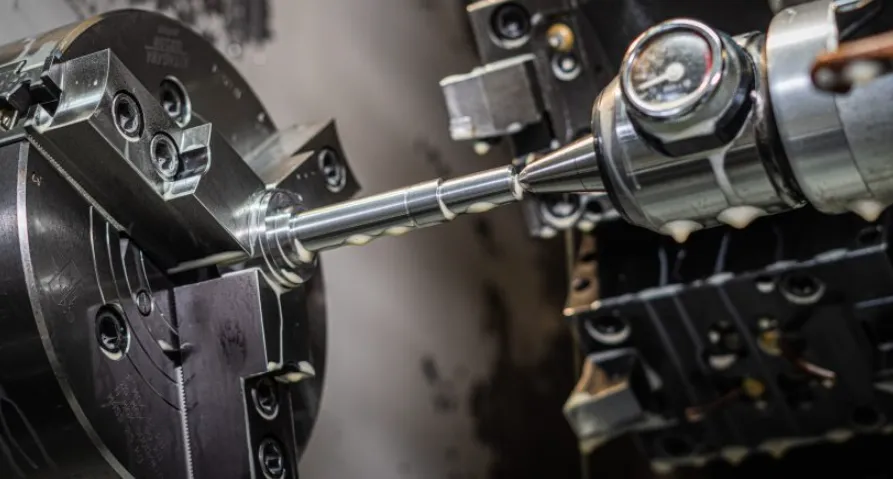

Lathes are crucial machine tools widely used in various manufacturing and fabrication processes. They specialize in shaping materials by rotating a workpiece against a stationary cutting tool.

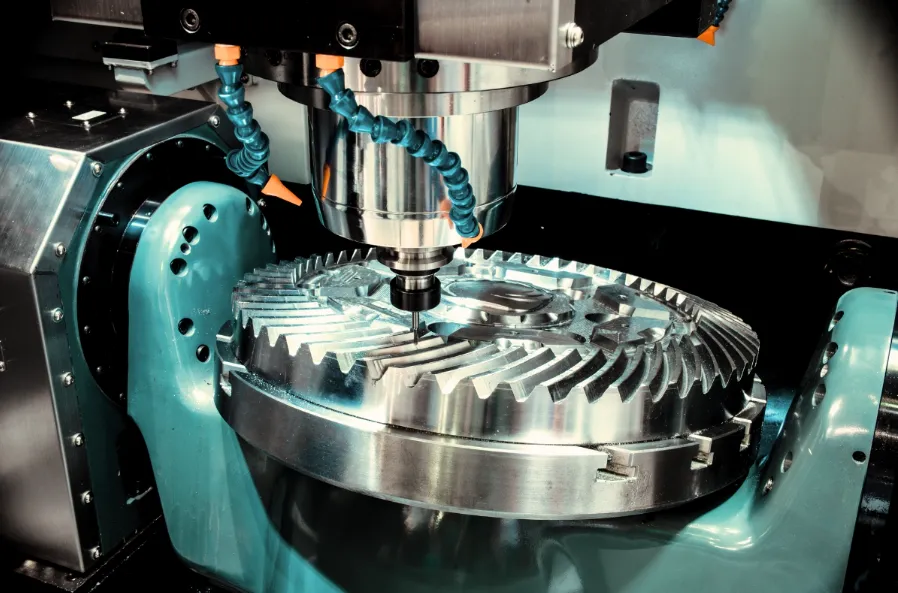

4-axis CNC (Computer Numerical Control) machining is a sophisticated technique that enhances the capabilities of traditional 3-axis machining by adding an additional rotational axis.

Machining titanium is a specialized process that requires a deep understanding of the material’s unique properties, challenges, and the appropriate techniques for effective manufacturing.

Global manufacturing is witnessing a steady push for higher precision and efficiency, driving a transformative evolution in sheet metal production. According to a Grand View Research report, the global sheet metal manufacturing market was valued at approximately USD 2300 billion in 2019, with an expected annual growth rate of around 3.7% in the coming years.

Cam manufacturing is a critical facet of the mechanical engineering and manufacturing sectors, integral to the functionality of numerous machines and systems. Cams are mechanical components used to convert rotational motion into linear or oscillating motion, enabling precise control over mechanical movements in engines, machinery, automation systems, and various industrial applications.

Swiss machining is a specialized form of metalworking that excels in producing high-precision components with tight tolerances and intricate geometries. Originating from the Swiss watchmaking industry, this machining technique has evolved to become a cornerstone in various high-precision manufacturing sectors, including aerospace, medical devices, electronics, and automotive industries.

3D machining has emerged as a pivotal technology in the manufacturing sector, revolutionizing how components are designed, produced, and inspected. This innovative process combines traditional machining techniques with advanced 3D modeling and printing technologies, enabling manufacturers to create complex parts with unparalleled precision and efficiency.

The manufacturing of automobile parts has reached new heights as technology continues to evolve and shape the automotive industry. Historically, the production of car components was a labor-intensive process, often characterized by manual assembly and limited precision.

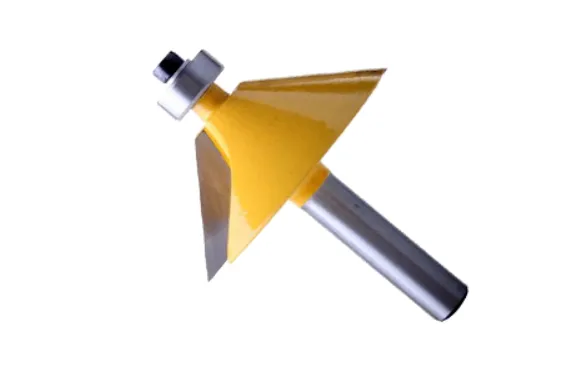

Chamfer bits are an essential tool in both woodworking and metalworking, renowned for their capability to create angled edges or bevels on materials. These bits are not only instrumental in improving the aesthetic appeal of joints and edges but also play a significant role in enhancing the functionality and safety of various components.

ROOM C-103, BAIFU BUSINESS GARDEN, NO.88 BAIFU ROAD, KUNSHAN, JIANGSU, CHINA

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

All of our products are available for sampling