Case hardening is a crucial process in metallurgy that significantly enhances the surface properties of materials, particularly metals. This treatment is essential for industrial applications where wear resistance, fatigue strength, and overall durability are paramount. In this article, we will explore the principles, methods, advantages, and applications of case hardening.

What is Case Hardening?

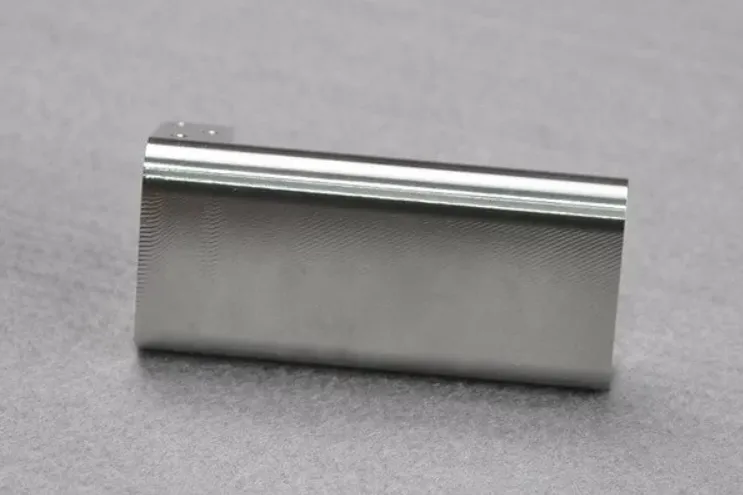

Case hardening refers to a variety of surface hardening processes that increase the hardness of the outer layer of a material while keeping the inner structure relatively soft. This creates a tough exterior that can withstand high levels of stress and wear, making it ideal for components that endure repeated impacts or friction.

How Does Case Hardening Work?

How Does Case Hardening Work?

The primary objective of case hardening is to alter the properties of the metal’s surface, forming a hardened layer. This is typically achieved through various methods, which can be classified into two main categories:

-

Diffusion Processes: In these methods, elements such as carbon or nitrogen are diffused into the surface of the material.

- Carburizing: This involves heating the steel in the presence of carbon-rich materials, allowing carbon atoms to diffuse into the surface. The typical temperature range for this process is between 750°C to 950°C.

- Nitriding: In this process, the material is exposed to nitrogen sources, typically at lower temperatures (around 500°C to 550°C). The nitrogen atoms diffuse into the surface, creating a hard layer of nitrides.

-

Thermal Processes: These methods involve heating the material and then rapidly cooling it to lock in desired properties.

- Quenching: This process is often used in conjunction with case hardening, where a metal is heated and then rapidly cooled, creating a hard martensitic structure.

Advantages of Case Hardening

The benefits of case hardening are numerous and can be critical for many industrial applications:

- Increased Wear Resistance: Case-hardened surfaces can significantly resist abrasion and wear, extending the life of machine parts and tools.

- Improved Fatigue Strength: The toughness of the inner core, combined with a hard surface, provides exceptional resistance to fatigue failure, making it suitable for high-stress applications.

- Reduced Friction: Many case-hardened surfaces exhibit lower friction properties, which can enhance the performance of moving parts and reduce energy consumption.

- Cost-Effective Longevity: By extending the lifespan of components, case hardening reduces the frequency of replacements and maintenance, leading to lower overall costs.

Applications of Case Hardening

Case hardening is widely used in various industries where durability and wear resistance are critical. Common applications include:

- Automotive Industry: Gears, camshafts, and crankshafts often undergo case hardening to withstand the high stresses encountered in operation.

- Aerospace: Components subjected to extreme conditions and pressures benefit from enhanced fatigue strength and wear resistance.

- Manufacturing Equipment: Tools such as drills, cutters, and dies are frequently case-hardened to maintain their cutting edges and reduce wear during operation.

Conclusion

Case hardening is a vital process that significantly enhances the surface properties of metals, making them suitable for high-performance applications. With methods like carburizing and nitriding, manufacturers can create components that resist wear, reduce friction, and improve overall durability. As industries continue to push for better performance and longevity in materials, case hardening will remain an essential technique in metallurgical engineering.

By understanding the importance of case hardening, industries can leverage this technology to improve their processes and products, ultimately leading to greater efficiency and reliability in their operations.