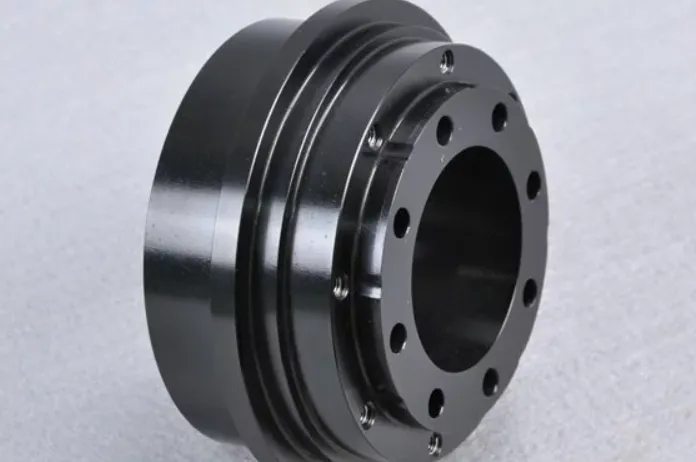

Black oxide coating,also known as blackening or black oxide treatment, is a widely used surface finishing technique that enhances the aesthetic and functional properties of metal parts. By creating a protective oxide layer on ferrous metals, this process provides corrosion resistance and improves lubrication, among other benefits. This article will explore the intricacies of black oxide coating, its applications across various industries, and the specific benefits it offers.

The Black Oxide Coating Process

The black oxide coating process involves several steps that transform the surface of metal components into a durable, black oxide finish. Here are the key stages of the process:

-

Preparation: The first step involves cleaning the metal parts to remove any oils, greases, or contaminants. Typically, this is done through various methods, including solvent degreasing, ultrasonic cleaning, or acid pickling.

-

Black Oxide Application: There are several methods for applying black oxide, including:

- Hot Black Oxide: In this method, metals are submerged in a hot alkaline solution containing oxidizing agents such as sodium hydroxide and nitrates. The temperature generally ranges from 285°F to 325°F (140°C to 160°C). This method provides superior corrosion resistance.

- Mid-Temperature Black Oxide: This process is performed at moderate temperatures (around 190°F to 250°F or 88°C to 121°C) and is widely used for its efficiency and better control over oxide layer thickness.

- Cold Black Oxide: A chemical solution applied at room temperature, this method is less common but offers a cost-effective solution for treating small batches of parts.

-

Sealing: After achieving the desired thickness of the oxide layer, the parts are treated with a sealant, often oil or wax, to enhance corrosion resistance and prevent moisture penetration. This step further improves the performance characteristics of the coated parts.

-

Quality Control: The final stage of the process entails quality checks, including visual inspections and maintenance of dimensional tolerances to ensure that the black oxide coating meets the specified standards.

Benefits of Black Oxide Coating

Black oxide coating offers numerous benefits for industries requiring reliable and durable metal finishes:

-

Corrosion Resistance: The primary function of black oxide coating is to provide a protective layer that enhances corrosion resistance. While it does not completely eliminate rust, it significantly slows down the oxidation process, making it ideal for environments subjected to moisture.

-

Aesthetics: The blackened finish offers a sleek, professional appearance that can be desirable for consumer products, tools, and machinery. It provides a uniform look, reducing glare and improving the overall visuals of precision parts.

-

Dimensional Stability: Unlike traditional coatings, such as paints or electroplating, black oxide is a conversion coating that does not add significant thickness to the part’s surface. This characteristic ensures that dimensional tolerances remain intact, making it suitable for applications where precision is critical.

-

Improved Lubricity: The porous nature of the black oxide layer promotes the retention of lubricants, thus improving wear resistance during operations that involve friction. This property is beneficial in applications such as gears and bearings, where lubrication is vital for longevity.

-

Cost-Effectiveness: Compared to other metal finishing processes, black oxide coating is relatively cost-effective, particularly in large-scale manufacturing. The process offers substantial savings long-term due to reduced maintenance and replacement costs associated with corrosion.

Applications of Black Oxide Coating

The versatility of black oxide coating allows it to penetrate numerous industries and applications, including:

-

Automotive Industry: In automotive manufacturing, black oxide is employed to treat parts such as brake components, gears, and under-the-hood components that require corrosion resistance and reduced glare. It is particularly popular for treated fasteners to prevent rust while maintaining aesthetics.

-

Tooling and Machinery: Tools formed from steel or cast iron often receive a black oxide finish for improved performance. This includes cutting tools, jigs, and dies, as well as industrial machinery components that require protection against wear and corrosion.

-

Firearms: The firearms industry heavily utilizes black oxide coating due to its excellent anti-corrosion properties and aesthetic appeal. Receivers, barrels, and other components benefit from the coating, which enhances their durability while providing a non-reflective finish.

-

Aerospace: In aerospace applications, black oxide coating is employed for surface treatment on various components, including fasteners, brackets, and structural components. The need for lightweight solutions with high corrosion resistance makes black oxide coating ideal in this sector.

-

Electronics: In the electronics industry, black oxide is utilized for metal housings, connectors, and other components that require both electrostatic discharge protection and enhanced conductivity. The coating can improve electronic performance while providing aesthetics.

-

Decorative Applications: Beyond functional uses, black oxide finishes are also applied to decorative items such as hardware fittings, jewelry, and art objects, where a visually striking finish is desirable.

Conclusion

The black oxide coating process serves an essential purpose across various industries by enhancing the durability, aesthetics, and performance of metal parts. Its corrosion resistance, dimensional stability, and cost-effectiveness make it an indispensable solution for many applications. As materials science progresses, the adoption of black oxide coating continues to rise, catering to the demands of advanced manufacturing and craftsmanship. By understanding the intricacies of this process, industries can leverage its benefits to enhance product quality and longevity.