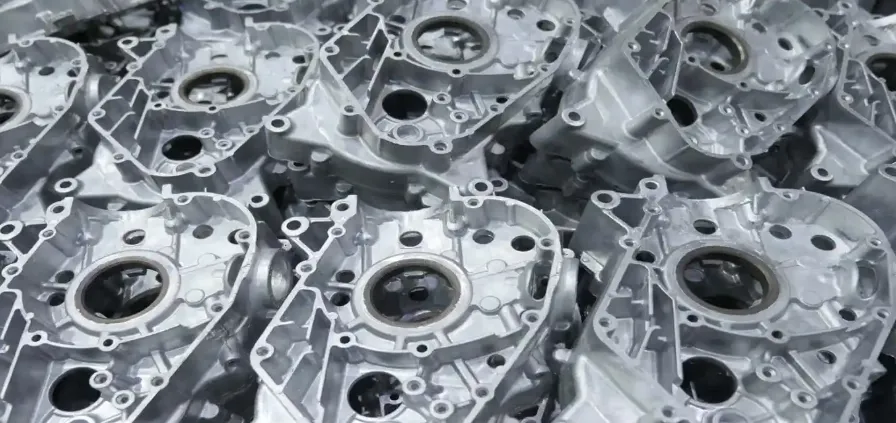

The aluminum die casting industry has evolved into a sophisticated manufacturing sector capable of producing complex, high-tolerance components at remarkable speeds. Modern cold chamber die casting machines now routinely operate at clamping forces ranging from 250 to 4,000 tons, with shot weights varying from a few grams to over 50 kg. This process dominates automotive component manufacturing, where approximately 65% of all aluminum cast parts are produced through die casting, offering the ideal balance of mechanical properties, dimensional stability, and cost efficiency.

Material Science Advancements

Contemporary aluminum die casting alloys have been specifically engineered to meet demanding performance criteria. The widely-used A380 alloy (AlSi8Cu3Fe) provides an optimal combination of fluidity and strength, with typical as-cast properties of 325 MPa tensile strength and 3.5% elongation. For structural applications requiring enhanced ductility, the modified A383 (AlSi10Cu2Fe) alloy offers 5-7% elongation while maintaining 310 MPa tensile strength. High-integrity components such as transmission cases increasingly utilize Silafont-36 (AlSi9MgMn), which achieves 250 MPa yield strength and 10% elongation in as-cast condition – properties previously only attainable through heat treatment.

Process Innovations

The introduction of vacuum-assisted die casting has revolutionized component quality, reducing porosity levels to below 0.1% in critical sections. Modern systems achieve vacuum levels of 80-100 mbar within the die cavity in less than 150 milliseconds, enabling the production of safety-critical automotive components like steering knuckles and suspension arms. Simultaneously, the development of multi-slide die technology allows for undercut features to be cast-in rather than machined, reducing secondary operations by up to 40%.

Equipment Technology

Today’s advanced die casting machines incorporate real-time process control systems that monitor and adjust parameters every 5 milliseconds. The Buhler Carat series, for example, uses 32-bit processing to control injection speeds up to 10 m/s with an accuracy of ±0.01 m/s. These systems maintain intensification pressures up to 1,000 bar during solidification, ensuring dimensional stability across production runs exceeding 500,000 cycles. The integration of infrared pyrometers for die surface temperature monitoring (±2°C accuracy) has extended die life by 30-50% through optimized thermal management.

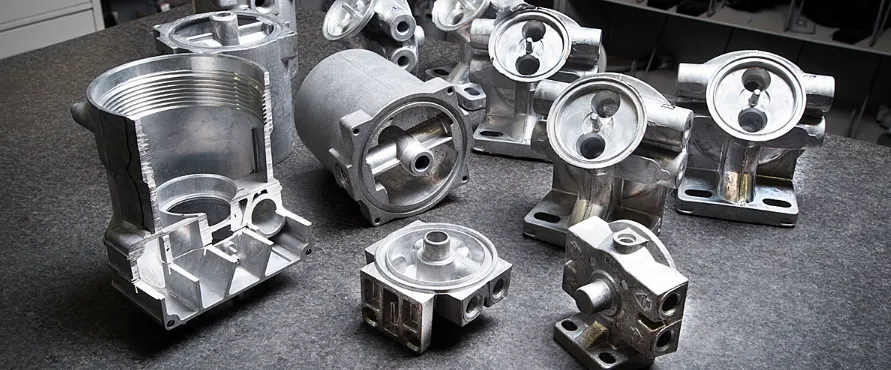

Surface Finish and Tolerances

Modern die casting achieves surface finishes ranging from 1.6 to 6.3 μm Ra without secondary processing. The process consistently holds dimensional tolerances of ±0.1 mm for the first 100 mm of part dimension, with an additional ±0.02 mm for each subsequent 100 mm. For critical bore diameters, post-casting machining allowances as small as 0.3-0.5 mm are now achievable through precise die design and process control.

Thermal Management Breakthroughs

Conformal cooling channels produced via additive manufacturing have transformed die temperature control. These complex cooling passages, following the exact contours of the die cavity, maintain temperature gradients within 5°C across the tool surface. The resulting improvement in solidification control has reduced cycle times by 15-20% while minimizing thermal stresses in the cast components.

Automotive Industry Applications

The electric vehicle revolution has created new demands for aluminum die casting. Tesla’s pioneering use of mega-casting technology produces entire rear underbody structures in a single 6,000-ton die casting operation, eliminating approximately 70 individual components from traditional designs. This approach reduces weight by 10-15% while improving structural rigidity by 20-30%. The industry is responding with new high-silicon alloys (AlSi17Cu4Mg) that maintain dimensional stability during the rapid solidification rates required for these massive castings.

Quality Assurance Systems

Advanced nondestructive testing methods have become standard in critical applications. Computerized tomography (CT) scanning detects internal defects as small as 0.2 mm, while automated vision systems inspect 200+ dimensional features per part at rates exceeding 60 components per minute. The integration of machine learning algorithms for defect recognition has improved classification accuracy to 99.7%, reducing false rejection rates by 40%.

Environmental Considerations

The aluminum die casting industry has made significant strides in sustainability. Modern systems recover and reuse 95% of the lubricants and release agents, while closed-loop water cooling systems reduce consumption by 80% compared to traditional setups. The energy efficiency of die casting has improved by 35% over the past decade, with state-of-the-art machines consuming as little as 0.35 kWh per kilogram of cast aluminum.

Future Directions

Emerging technologies promise to further transform aluminum die casting. Semi-solid casting techniques like rheocasting are gaining traction, offering 10-15% higher mechanical properties than conventional die casting. The development of self-lubricating die coatings using graphene composites shows potential to extend tool life by 300%. Meanwhile, the integration of Industry 4.0 technologies enables real-time process optimization across networked foundries, with initial implementations showing 15% reductions in energy use and 20% improvements in yield rates.

As material science, process control, and digital technologies continue to advance, aluminum die casting remains at the forefront of high-volume manufacturing solutions, combining the versatility of aluminum with the precision and efficiency demanded by modern industry. The process continues to evolve beyond its traditional applications, finding new uses in aerospace components, electronics enclosures, and renewable energy systems – each application driving further innovation in this mature yet constantly advancing manufacturing technology.